In January 2014, Schneider Electric completed its acquisition of Invensys Plc. The deal, valued at $5.6 billion, was reached after Schneider fended off competition from other suitors, including Emerson Electric and ABB. Now that some of the dust has settled on Schneider’s purchase of Invensys, a clearer picture is beginning to emerge on what the combined company will look like, as well as Schneider’s future prospects in the process automation marketplace.

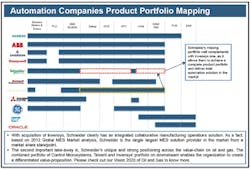

Prior to acquiring Invensys, Schneider was missing some key components to compete as a mainstream process automation supplier—namely in the area of Distributed Control Systems (DCS), safety systems, and Enterprise Asset Management. Through Invensys, Schneider now has a strong presence in each of these key categories and can compete head-to-head with other leading automation service providers (Figure 1).

“Acquiring Invensys was always about creating and delivering additional value to customers,” says Mary Ramsey, Schneider’s senior vice president of U.S. Industry Business. “The Invensys portfolio of offerings improves our ability to help our customers become safer, more secure, and more agile, as well as achieve new levels of performance, efficiency and profitability in real time.”

According to Muthuraman “Ram” Ramasamy, industry manager for Frost & Sullivan’s Industrial Automation and Process Control research unit. “The acquisition [of Invensys] kindles a transformational stepping stone for Schneider as it evolves from an product company to a technology and solutions company. Progressively, we predict that Schneider will deliver an integrated software platform focused on big data analytics and combine it with Invensys’s offering in order to create a uniquely positioned managed digital service offering within the next 2 to 3 years. The timing has never been better. The industry trends, market challenges resonate very well with the synergistic portfolio of Schneider.”

From discrete to process, Ramasamy says Schneider Electric has acquired critical mass to expand on its technologies, expertise and services, and gained access into energy-rich process industry segments. He says the convergence of Invensys’s process-intense portfolio with Schneider’s existing discrete portfolio enables Schneider to be a single-source supplier for the entire plant.

The ability to operate as a full-service provider is a key capability in today’s process automation marketplace, particularly in the oil & gas sector where the trend toward Main Automation Contractors (MACs) and Main Electrical Contractors (MECs) is strong. Ramasamy says oil & gas companies increasingly will only do business with suppliers who can provide end-to-end solutions for both process automation and electrical. With Invensys in its fold, Schneider is now one of a few companies that is positioned to serve as both MAC and MEC, i.e., MAEC (Main Automation Electrical Contractor), on large projects. Ramasamy says recent analysis on MACs in th oil & gas market has also revealed a trend toward Main Information Contractors (MIC), which adds another element to the mix of solutions Schneider may need to deliver to meet the needs of oil & gas companies going forward.

“We predict that the synergies enjoyed by Schneider and Invensys [will] make it the single largest solution provider with equal strengths across the oil & gas value-chain,” says Ramasamy. “As this is a core industry vertical with top-dollar capital spending in the next few years, Invensys’s strength in upstream and downstream combined with Schneider’s strength in midstream creates a unique solution offering in the oil & gas market that no other competitor possesses.”

“Industrial automation is a critical business driver for Schneider Electric’s clients through its ability to increase productivity, manage input costs and control margins,” says Ramsey. “The Invensys acquisition is a big step in allowing Schneider Electric to bring a more complete offering to market.”

Another key advantage Invensys brings to Schneider is in personnel, as Invensys has long-term and reputable expertise and strong industry connections. “Acquiring Invensys technology and people strengthens Schneider Electric’s position in the integrated industrial automation, software, and energy management markets, delivering an unmatched portfolio of proven innovation and strong brands,” says Ramsey.

Ramsey believes the addition of Invensys positions Schneider particularly well in the software space, with a portfolio of offerings that can help end-users anywhere in the plant and across their process, from design and simulation to business systems.

While early signs point to a range of new opportunities for Schneider now that it has added Invensys, the company’s go-to-market strategy will be key. “It’s all about the integration—both internal and external,” says Ramasamy. “While solutions are important to a company, so are the people who build it. Not a lot has been spoken about this, but Frost & Sullivan believes that the intrinsic skillsets of erstwhile Invensys [will] be critical to long-term success of the combined organization.”

Ramasamy says Schneider must be shrewd in its approach regarding the integration of product lines to optimize its go-to-market strategy. “To merge or not to merge, that is a key question,” he says. “Invensys’s and Schneider’s solution portfolios both complement and contrast each other in terms of brand identity, offerings and strategy.”

Matt Migliore is the director of content for Flow Control magazine and FlowControlNetwork.com. He can be reached at [email protected]. Connect with Matt on LinkedIn.