By using an NVLAP-accredited flowmeter calibration provider, calibration service customers gain a high confidence level from knowing their measurements have the closest possible correlation with National Institute of Standards and Technology (NIST) requirements. Indeed, accredited labs can be viewed as an extension of the NIST itself and its accuracy standards. Flow calibration will be the focus of an “Outlook” article in the July issue of Flow Control magazine. This blog post is designed to wet your appetite for the July article and provide some insight on the importance of NVLAP accreditation for flow calibration.

In addition, NVLAP accreditation requires the use of correlation flowmeter testing periodically to ensure the calibrator is repeating from the time of system calibration certification. This is not only done internally but externally by means of NIST proficiency testing. This is critical to make sure the calibrator not only produces repeatable results, but also provides statistical data indicating bias and evidence that flowmeters were calibrated within the stated uncertainty of the system. Plus, it ensures that calibration uncertainties, as documented on the NVLAP Certificate of Accreditation, are maintained.

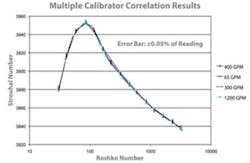

Flow Dynamics, a Badger Meter NVLAP-accredited primary standards calibration laboratory, continually runs correlation studies on the performance of its positive-displacement calibrators. The intra-laboratory study shown in the graph here was designed to compare the performance data of each calibrator. In this case, one correlation master flowmeter was run on calibrators of various sizes, including 65 GPM, 300 GPM, 400 GPM, and 1200 GPM. The graph shows how well the Roshko/Strouhal data compared on each calibrator. The error between each calibrator falls well within +/-0.05 percent of reading. This data demonstrates the capabilities of a quality calibration laboratory, which practices and conforms to NVLAP-audited procedures.

Ron Madison, is manager of Calibrator Sales & Marketing at Badger Meter. He can be reached at [email protected].