Eight out of ten power plant operators do not realize what they are risking if they allow seal wear in hydraulic actuators to simply take its course. This practical guide explains how to cost-effectively prevent damage and production downtime with predictive planning.

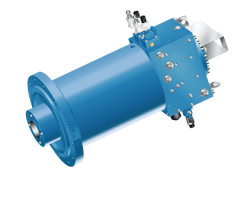

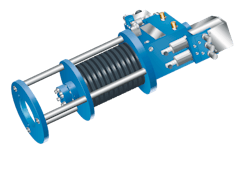

In order for gas and steam turbines to generate electricity with the right output and rotational speed, the supply of media must be precisely controlled. Hydraulic actuators ensure exact control of the valves. In the event of a malfunction, they also carry out an important safety function by mechanically moving the valves into a safety position via spring force to disrupt the flow of medium or redirect it. To ensure this in the long term, it is essential that the hydraulic actuators for gas and steam turbines are inspected and maintained at regular intervals in accordance with the relevant legal regulations and manufacturers’ recommendations. The reason: Each hydraulic actuator — no matter the quality — exhibits wear due to operational reasons. The wear starts on the seals and, in the absence of maintenance, may extend to other components. Anyone who disregards this and waits until an obvious failure occurs, risks high repair costs and long waiting periods until unrestricted production can be resumed.

Key insights and considerations

Damage to actuators can be caused by a variety of events, such as gradual aging and wear, maintenance errors or extreme heat and discharge. Also, poor maintenance may result in diminished quality control and even permanent damage to machine integrity. To reduce costs and avoid damage or prolonged downtime to the machine, long-term maintenance planning and testing are recommended.

Imminent loss of the SIL capability

If the specifications from the operating instructions and the safety manual are not complied with — for example, maintenance requirements and proof-test intervals — or if the actuators are not properly used, under certain circumstances, the drive loses its SIL conformity and thus its suitability for safety-related applications. Improper usage includes the use of dirty or contaminated hydraulic oil. This can lead to failure of the solenoid valves and cartridge valves, as well as increased wear on the piston rod seal and the piston rod. In addition, unsuitable placement in the escaping steam can cause damage due to overheating (discussed further in the following section), which can subsequently result in strong corrosion on safety-related components, such as magnetic and cartridge valves, piston rod and spring assembly. Last but not least, a lack of regulation or control poses a risk to the SIL capability, because inadmissible oscillations could cause significant wear in a short time.

Damage causes

Ongoing seal wear

If the piston and rod seals are not replaced according to the schedule for the actuator — at the latest, after six years — the wear will lead to functional impairments. First, leakage occurs. Later, there is damage to the piston and the piston housing. Depending on the circumstances, this leads directly to failure. On one hand, the wear ensues regardless of the product quality due to the aging process of the sealing material, which gradually becomes brittle and porous, so the sealing effect decreases. On the other hand, the frequency of the changes in movement, in combination with the stroke length, plays a role. Therefore, the strokes are determined by the control system to ensure an adequate lubricating film and thus low-wear operation for the seals.In the short-stroke range, constant operation leads to increased seal wear and damage to the mating surfaces. Especially in the case of short strokes at high frequency, the replacement intervals for seals recommended in the maintenance schedule can be significantly reduced. Regular monitoring is essential. In the case of actuators that only extend to short strokes or remain in one position over a longer period of time — depending on the application, this could be several weeks or months — separated seal particles mostly remain in the chamber, as there is hardly any exchange of the oil. Thus, contamination on the inside of the cylinder builds up and the sealing rings wear down more quickly.

Incorrect maintenance or assembly

Apart from the wear, maintenance or assembly errors could also be the cause of permanent damage to the actuators. A common source of error is the alignment to the steam or gas valve. If a valve and piston rod are not properly aligned, lateral forces acting on the coupling place stress on the guide belts. Consequently, the guide belts and the seals wear excessively. A further cause of damage resulting from faulty handling is the filling of the hydraulic system with an incorrect fluid. This can trigger a chemical reaction between the seal and the fluid, which accelerates the process of wear and tear.

Special risks associated with steam valves

Power plant operators who generate electricity by means of steam should also observe the leak tightness of the steam valves in the direction of the cylinder. If the hot medium (more than 500°C) flows long enough over the outer coating of the actuator, the coating can “burn off” and the surface becomes corroded. Apart from this obvious damage, the spring assembly inside the cylinder can also be damaged, which, in the event of a malfunction, subjects the valve purely mechanically up to 400 kN force in the locked position.

At the interface to the armature — the coupling — the ambient temperature must not exceed 200°C. As a result of the effects of excessive heat, the existing anticorrosive coating — consisting of a layer of wax on the Belleville washer system — can be damaged. If a rusty spring cup breaks, the actuator loses its safety function. In this case, the component requires an immediate overhaul in a manufacturer’s certified service center.

In addition, uncontrolled steam discharge can damage the actuator due to overheating of the hydraulic fluid, because the fluid temperature must not exceed 70°C in circulation. If the system cannot compensate for the influx of heat, the hydraulic oil will be “burnt.” This means it becomes viscous and sticky. The seal wear increases, while valves and other components lose their freedom of movement and function.

Consequences of inadequate maintenance

Reduced control quality

Even before the seals lose their originally intended function through continued wear, increasing internal or external leakage leads to energy losses. The accompanying temperature rise promotes wear and tear in other areas of the hydraulic system. Another consequence of the increased leakage is diminished control quality. Therefore, under certain circumstances, the system would no longer be able to adjust the required performance of the turbine with sufficient accuracy.

Mechanical damage: Worst-case scenario

If the damage of the seal system has deteriorated to such an extent that it leads to mechanical contact between the piston rod and cylinder housing, the main components suffer permanent damage. Due to the leakage that occurs, the actuator can no longer properly perform its regulatory function. Although this is not safety-relevant with the Belleville spring washer system intact, the damage is much greater. The seal wear increases, while valves and other components lose their freedom of movement and function. The reason: The main components of the actuator, such as the cylinder housing and piston, are generally not stockable items for the manufacturer due to the large variance. Some parts must even be cast and then machined. In the worst case, this could take weeks or months. If the waiting period occurs during the high season, operators must possibly accept painful constraints to production.

Recommendations for practical use

Preventing the worst-case scenario

To avoid the worst-case scenario in a cost-efficient manner, operators should not only comply with the maintenance rules and instructions, but also schedule major inspections in a timely manner. This way, the manufacturer has enough time to provide the necessary parts, carry out repairs and perform the final functional test.

If the actuator must be repaired, it is essential that the power plant operator ensure that the final examination also includes the safety functionality and that everything is documented in detail. This is the only way to ensure that, in the event of a malfunction, the actuator operates perfectly and the SIL capability is maintained. However, only the original manufacturer can guarantee this, as they have the original specification, e.g., for the spring tension. Alternative providers cannot guarantee this, because they do not have the same materials, nor do they have specific information regarding rigidity, for example. Only with the right combination of hydraulic fluid, piston rod, spring assembly, corrosion protection, etc., can the manufacturer achieve the same longevity and the same safety level as with the initial delivery.

Performing proof-tests

To ensure the SIL conformity in the long term after five years — at least every six years or after 50,000 hours of operation — a proof-test must be performed. During this test, the manufacturer inspects all safety-related components in accordance with the maintenance requirements. If components with restricted functionality are discovered, or during preventive maintenance, they will be replaced. Furthermore, a functional test is always performed in accordance with the instructions for commissioning of the system and its safety-related functions, as well as according to the manufacturer’s operating instructions and documentation. The actuator is tested the same as during the initial commissioning of the system. The reason is, before every recommissioning, the user is required to validate the safety function, including the safety period of the safety system, and to traceably document it.

Predictive planning

In terms of risk minimization, the standard overhaul with seal replacement should be a matter of course – every two to six years, depending on the maintenance schedule and load stress. Power plant operators should plan approximately 10 working days for the duration of this measure, including functional testing, plus transport as well as import and export from the country, as the case may be. If the accompanying inspection reveals damage to the actuator, the manufacturer will inform the customer with corresponding photographic proof and submit a subsequent offer. The further procedure will be jointly discussed. If there is still time for the repair, replacement parts can be ordered or manufactured at an early stage for a later maintenance step. In addition to the regular seal replacement, the condition of the spring assembly should be a major focal point. This can be done in advance of a maintenance operation by a specialist, checking the spring force and apparent condition (e.g., rust formation).

A good point in time for major overhauls or repairs is during a low-output phase of the power plant — in spring, summer or winter, depending on the geographical location. After the overhaul, OEM manufacturers typically offer a 12-month guarantee on the entire drive.Maintenance backlog

If the maintenance has been neglected in the past, the operator should lose no time and immediately contact the manufacturer. Discussing matters with experts makes it possible to better assess the condition of the actuators to minimize time and financial risks. Typically, the manufacturer first informs about the technical interrelationships and then explains the various options for action. Based on age and maintenance history, it can now be decided as to whether the device needs to be returned for a standard overhaul or whether it is sufficient to inspect the device within the scope of an on-site visit to the power plant. There, field service specialists assess the current condition of the system and, if necessary, carry out additional measurements. If there are several actuators of the same type in the same power plant, under certain circumstances, it is worthwhile to stock a spare device to bridge a gap in maintenance times.

Standard overhaul at the manufacturer’s facility with original spare parts includes:

- Visual inspection of the condition in the delivered state with photographic documentation

- Disassembly: Cylinder housing, piston rod, piston, spring unit, add-on components and measuring unit

- Verification:

- Cylinder housing, piston rod and piston and the measurement of the running surfaces and adherence to permissible wear limits, in accordance with the design requirements, and the chrome layer in terms of minimum thickness

- Spring unit: visual inspection of the Belleville spring washers and protective pipe

- Add-on components (e.g., control block, valves and filters)

- Measurement units: position transducer and limit switch

- Drafting of findings report with photo documentation

Repair by the manufacturer with original spare parts includes:

- Cleaning of all components

- Resealing of the sealing elements of the cylinder and all components with certified OEM spare parts, ensuring operational safety

- Finishing of the running surfaces by polishing with precision processing machinery

- Maintenance of the filters by replacing the seals, filter elements and the clogging indicator

- Replacement of all wear parts, e.g., air filters, measuring ports, plug screws, bolts, locking rings and guide rings.

- Assembly with manipulators and state-of-the-art lifting devices

- Functional testing of all assembly components according to specified criteria and with settings per the initial delivery to ensure operational safety

- Full functional test of all specified values according to the initial delivery state

- Creating a test protocol

Conclusion

It is advisable for power plant operators with steam or gas valves to protect hydraulic actuators against unplanned downtime and avoid the ensuing costs. The easiest way to do this is to adhere to the manufacturer’s maintenance schedules from the first day of operation. In addition, regular condition analyses by field service specialists can help discover unusual damage and the error sources and initiate immediate countermeasures or plan them in a timely manner. In case of a maintenance backlog, it is urgently recommended to immediately contact the manufacturer to jointly assess the situation and discuss the next steps. This ensures that power plant operation can continue unrestricted or with planned maintenance.

Volker Tenhaeff is the head of service sales support for industrial hydraulics at Bosch Rexroth. He has more than eight years of global experience in sales, service and application engineering in hydraulic drive systems for various industry sectors such as metallurgy, marine and power generation. He holds a Master of Engineering in mechanical engineering from Technical University Munich, Germany.