Pipeline ball valves (as shown in Figure 1) are routinely misapplied in the field. For example, isolation valves are often used in control applications, leading to poor flow control and possible valve damage. This is because their seal and packing designs are typically unsuited for throttling applications.

In most cases, control applications have relatively high pressure drops across the valve that can lead to increased noise, cavitation and vibration. Without adequate trim, a control valve is unsuited for the application and can be damaged by noise, cavitation and vibration caused by these pressure drops. Accurate controllability greatly depends on the ball shaft connection, adequate shaft guiding, packing design and actuator style. Isolation valves do not have the required features for these types of throttling applications.

On the other hand, control valves should not be used in isolation applications. Control valves are designed to have inherent leakage as specified by ANSI/FCI 70-2, which typically makes them unsuited for isolation applications. Most control valves are also not fire-tested like isolation valves. And, flow coefficient (Cv) is calculated differently for isolation and control valves.

Inside isolation valves

On pipelines, isolation valves are often used to isolate process fluid from moving downstream when a nearby control valve is closed. For every control valve, there should be an isolation valve upstream and downstream if applicable.

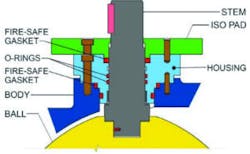

Isolation valves use a nonmechanically retained seal to leverage seal injection ports for tight shutoff. These valves have O-ring style packing (see Figure 2), ideal for low-cycling applications, and the packing includes a fire-safe gasket. These valves can either be manually operated or automatically operated by an actuator.

Figure 2. Isolation valves have several features designed for bubble-tight shutoff and fire safety.

The ball/shaft connection is typically pinned or has a double-D style design. The actuator/valve shaft connection is keyed. These connections have inherent lost motion in the design, and the valve can perform poorly when throttling.

When selecting an isolation valve, look for:

- Seal injection ports for tight shutoff

- Suitability for buried service applications

- O-ring packing construction

- Suitability for manual operation

- Compliance with API 6D

While isolation valves are good for low-cycling applications, they are not ideal for dynamic performance. Isolation valves are not designed to be installed at angles between 0 and 90 degrees like control valves and should only be fully closed or wide open.

General service control valves

General service applications do not require noise attenuation, cavitation protection or tight control; therefore, general service valves do not have splined shafts or attenuators but are still equipped for dynamic applications. Severe service applications are those in which excessive noise or cavitation is expected.

Figure 3. A general service control valve, such as this Fisher Model V270, is designed for line pressures of up to 1480 psi.

A general service, trunnion-mounted and full-bore pipeline ball valve (as shown in Figure 3) can be used in both control and isolation applications. It has the mechanically retained seals necessary for throttling without the risk of seal failure. Taking a high pressure drop across the valve while throttling at low degrees of travel can cause nonmechanically retained seals to be sucked out of the carrier, resulting in damage to the seal and preventing the valve from being shut off.

Other features include live-loaded packing and a robust drive train designed to absorb energy properly at mid-travel. As the control valve throttles, it absorbs energy, creating side-loading on the valve shaft. The live-loaded packing guides the valve shaft under these conditions. Mechanically retained seals prevent damage to the trim during pressure drops often experienced when flow is throttled down significantly.

When selecting a general service control valve, look for:

- Design compliance with both B16.34 and API 6D

- Mechanically retained seal inserts

- Live-loaded packing

A general service control valve can be used in almost any application that does not require noise reduction and extreme precision. However, a double-D or pinned ball shaft connection does not provide the highest performance because general service applications generally do not have stringent throttling requirements.

Severe service valves

Typical severe service applications require high-performance actuation. This could be needed for fast stroking speeds or higher cycles. Proper O-rings, actuator accessories and other valve components and features need to be considered when selecting valves for severe service. To greatly reduce lost motion, a severe service, trunnion-mounted and full-bore pipeline ball valve (as shown in Figure 4) has splined ball-to-shaft and shaft-to-actuator connections.

Figure 4. A severe service, anti-surge valve, such as this Fisher Model V260A, has a rugged actuator and other features for fast stroke, long life and high performance in demanding applications.

Cavitation can be a problem in severe service applications. When pipeline fluid flows through a fixed restriction like a control valve, the pressure drops. Depending on the severity of the pressure drop and the fluid properties associated with the process, this can cause cavitation.

Cavitation occurs when the pressure at the vena contracta falls below the vapor pressure of the process and then recovers downstream. Cavitation can lead to extensive damage to valve bodies and trim. In gas service, noise and vibration can be generated by high pressure drops across the control valve; therefore, dealing with these sources of cavitation and noise is essential in preventing damage to the valve in severe service applications.

Pipeline ball valves can be supplied with various types of anti-cavitation and noise-protection trims to stage the pressure drops and prevent cavitation. This allows the valve to not take the entire pressure drop at once. Aerodome-style trim can be used to keep the noise level down to a reasonable level. These trims can be customized for different startup cases and for full capacity to fit the desired application.

When selecting a severe service ball valve, look for:

- Anti-cavitation trim

- Splined-shaft connections

- Fast-stroking capabilities

- Adaptable product platform for special constructions

Pipeline applications

Ball valves can be used in the following applications:

- Within a gate station

- As a worker/monitor valve

- To provide over-pressure protection

- As a pump station pressure-control valve

- Within a compressor station

- To provide anti-surge protection

As pipeline gas travels from higher-pressure pipelines to lower-pressure pipelines in cities, the gas passes through a gate station with worker and/or monitor valves to reduce pressure. The worker valve handles the pressure drop and maintains a lower pressure downstream. This considerable pressure drop generates noise and vibration.

Typically, noise attenuation trim is required along with features that provide tight throttling control. The monitor acts as a backup to the worker; if something happens, it takes over and controls the pressure downstream. While the monitor valve may require less throttling control, it may still be needed to perform like a control valve.

An over-pressure protection, or super monitor valve, often performs as a general service valve. It can be upstream of the worker and monitor or at the inlet of a gate station or compressor station. If the station needs to shut down, this valve will close, so throttling control and shutoff are important for this application.

A pump station pressure-control valve minimizes the pressure drop when fully open. These valves need to be able to handle transient conditions with higher pressure drops — often occurring during startup — that could lead to periods of cavitation.

Compressor stations may be placed every 50 to 100 miles on a pipeline to help boost pressure. Typically, an anti-surge control valve is used to prevent the compressor from experiencing surge, which can cause costly damage to the equipment.

Conclusion

Proper ball valve selection will result in more uptime and better performance, and it will prevent "sucking out" of seals and damage to the drive train. The correct valve will provide appropriate control and reduce required valve maintenance.

Users should check published specifications to ensure the valve meets the aforementioned requirements. The valve manufacturer should be able to provide technical assistance and demonstrate that the valve being considered has been used in similar pipeline applications.

Alex Schick is a product marketing manager for Fisher Rotary Valves at Emerson. He is a graduate of the University of Iowa with a B.S. in Engineering and an MBA. Schick has been with Emerson in Marshalltown, Iowa, for five years.

Joe DeMonte supports Emerson’s flow control products as the global midstream oil and gas and LNG industry manager. He is also Emerson’s subject-matter expert on anti-surge valves. DeMonte received a B.S. and M.S. in engineering from the University of Iowa.