The 2008 commodities market crisis served as a wakeup call for industry, forcing companies to find ways to optimize production. However, even with the changes that were made, the challenges process industries face are still adding up. There is the pressure of global competition from companies with newer, more advanced facilities. Plants that can meet short lead times and high volumes have a distinct advantage. At the same time, the skilled, experienced process and reliability workforce is aging. And in some facilities, the total number of staff has been reduced, increasing the amount of responsibility on every employee.

Most professionals in the process industry would agree that reliability is the strategic answer to these challenges, but how are companies solving for it? Some users have figured out that integrated control and asset management offer one way to change the equation. Access to real-time optimized control and asset health information helps operators make the right operational decisions and maintenance and reliability teams increase their effectiveness—critical factors in improving reliability. In the simplest terms, the key variables include understanding failures before they occur, knowing what to do and how, and focusing resources on the most important issues.

Minimizing disruption and improving performance

Operators monitor the plant from the process perspective. They’re focused on the quality, throughput and stability of the process. The operator acts only when he sees a problem or unexpected change in the process variables. The operator will try to solve the problem with control and operations tools. If those tactics don’t work, the operator will engage the maintenance team to help diagnose why the controls are not responding.

READ ALSO: Emerson Touts Reliability Focus, Showcases New Products at 2014 Users Exchange

Maintenance teams monitor the plant from the equipment condition perspective. The maintenance technician is typically the first one to spot a potential problem, and the operator hears about the problem when maintenance calls to plan for repair or replacement.

At some plants, the interaction between the operator and maintenance technician has a different twist. With online monitoring, maintenance technicians are getting information about changes in asset health before problems impact production. After analyzing a potential issue, the criticality of the asset and the rate of change, the maintenance technician can provide a meaningful update to the operator, who can in turn use that information to determine the best action for the process. An example from a chemical industry user demonstrates how the interaction plays out in real life. In this instance, a low supply pressure alert on a six-inch disk level control valve prevented a valve failure. The maintenance team had defined the appropriate air supply pressure range. Based on a low-pressure alert and diagnostics, the maintenance team determined that the critical rotary valve had to be removed immediately for repair. Without sufficient air pressure against the diaphragm, the piston would not be able to open the valve. The maintenance team informed the operator and he took the necessary action to prevent impact to production. After the valve had been pulled, the team could see that the piston was deeply scored and the diaphragm was cut. It would have been only a matter of time before the valve failed shut, causing a significant and costly upset in a primary process unit.

Working with their reliability team, operators are identifying actions they can take to enhance performance. For example, a reliability team spotted a drive over-range alert in the asset management system. The alert indicated a partially plugged sensor tube in a mass flowmeter. The team contacted the operator to ask if he had observed any issues with the loop. The operator said that from his end everything looked fine. Based on the reliability team’s diagnostic information, the operator performed an automated backflush sequence without shutting down the production unit. At his workstation, the operator observed the dramatically improved performance of the mass flow and density variables provided to the control system as a result of his action. By avoiding unplanned downtime, the company prevented the production loss of $400,000.

With these types of successes, site process engineers have experienced how predictive monitoring can help them improve performance by addressing underlying asset conditions. Many engineers are asking for email alerts for key assets in their production areas in order to enable them to be more proactive with operational decisions.

More precise troubleshooting

Helping maintenance and reliability teams become more effective and efficient is another key variable. Case in point: Operators use make-up nitrogen to control top pressure of columns when column pressure is too low. When operators were having trouble controlling that top pressure in a column, they added the gas frequently to maintain overall column pressure. The control system, however, indicated that the valves were operating properly, meaning there should have been no leakage. But when technicians checked the digital valve positioner using the asset management software, they determined immediately that the globe valve controlling the discharge of nitrogen to a flare was actually slightly open. The technicians knew this because the valve provided its actual valve position to the control system and asset management system. While the technicians eventually would have found the problem, pinpointing it quickly enabled them to adjust the positioner, which in turn allowed operators to stabilize column pressure.

That maintenance action prevented further nitrogen loss and allowed uninterrupted production of a quality product. The company avoided an unplanned shutdown and saved an estimated $20,000 in energy and production losses, as well as repair costs.

Better planning, increased efficiency

Confidence in the power of prediction, based on actual experience, has impacted maintenance practices in other ways. Maintenance teams are extending the time intervals for preventive maintenance on equipment. In the past, preventive maintenance schedules were overly protective. In fact, users have often acknowledged they implemented schedules simply because that’s what was recommended by the original equipment manufacturer. As production managers have become more comfortable with the fact that critical process equipment is adequately protected through monitoring and the application of the field-generated diagnostics, many plants have substantially reduced the amount of time devoted to preventive maintenance.

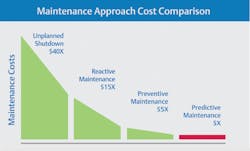

The high cost of reactive maintenance is caused by lost production, while the cost of preventive maintenance is driven by the unnecessary repair of equipment. Excessive preventative maintenance costs can add up as illustrated in Figure 1. Plants that are expanding their use of predictive maintenance are reducing their maintenance costs by doing targeted repairs only while increasing equipment availability.

Lean operations and reliability teams are effectively using notifications and alerts to target the work to be done. With the recognition that lines between operations and maintenance roles are blurring, some users are now using such techniques as custom email notifications and mobile alerts for the alarms generated by the control system and the asset management application. This ensures the right people get dynamic notification no matter the time of the day. The notification provides criticality, device tag, description, and other essential information. Managers and operators get the information they need in time to take action. Technicians don’t have to be in the reliability shop monitoring their computer systems; instead they’re freed up for other critical tasks in the plant.

Another way some users have improved reliability is in the way they use predictive tools to identify work early for effective maintenance planning. The result is minimal-to-no interruption or impact on production. To get the full benefit of early identification, some customers have integrated asset management with a computerized maintenance management system (CMMS). Using the asset management software, reliability teams access health, status and diagnostic information for assessment and prioritization of faults based on the asset’s criticality rating. Once a problem has been identified, the CMMS can generate the appropriate work order, ensuring the maintenance action can be completed in a controlled, safe, and effective fashion that does not impact production.

The payoff

The stakes are high. For sold out units requiring near 100 percent availability at full rates, the cost of downtime is significant. In a critical area of the plant, the need to pull and replace a mass flowmeter unexpectedly could result in hundreds of thousands of dollars to millions in lost profit. In addition, companies can face fines if they can’t meet their commitments—not to mention the impact on future sales.

The stakes are high, but so is the payoff for companies focused on reliability. They’ve seen significant improvement in process uptime. Some users have reported increases of production on stream time as much as 10 percent as a result of reliability efforts. For others, plant downtime has decreased from 18 percent to 4 percent. And companies have seen savings of more than $250,000 from avoiding production loss.

Plants have also experienced real savings in maintenance dollars through more efficient practices. Users have improved maintenance productivity by 10-15 percent. Based on predictive intelligence and asset prioritization, the knowledge of where to focus their attention has resulted in decreases in maintenance spending by as much as 10 percent.

Improved reliability is helping businesses achieve higher throughput and increased profitability. One company reported that sustained, better-than-expected production of one product led to investment in developing other product lines. Improvement has been realized in additional unexpected ways. For example, a reduction in waste going to a landfill from 1.5 percent to 0.3 percent.

The formula for reliability will continue to evolve. But based on the results users have experienced, integrated control and asset management will be part of the equation.

Claudio Fayad leads the product management team for Emerson’s DeltaV distributed control system and DeltaV SIS safety system offerings. Mr. Fayad is originally from Brazil, where he earned his Electrical Engineering degree and an MBA. He also received a post-MBA through the executive program at Northwestern University’s Kellogg School of Management. Mr. Fayad has held a variety of roles in the automation industry, including application and system engineering, engineering and sales management, and business management.