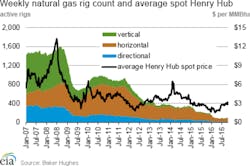

US experiences highest weekly increase in natural gas rig count in two years

Graphic courtesy of the EIA

The weekly natural gas rig count increased by 11 during the week ending October 14, 2016, according to American industrial service company Baker Hughes. One hundred and five natural gas rigs are now active in the U.S. This is the largest increase in natural gas-directed rigs since the week ending October 31, 2014, when the natural gas rig count increased by 14. Although this is the fourth consecutive week that Baker Hughes reported week-on-week increases in the number of active natural gas rigs, the current number in operation is still below last year’s total of 192 at this time, and it equals only about 25 percent of the recent peak of 401 natural gas rigs in operation in September 2013. Natural gas-directed rigs peaked at 1,606 in summer 2008.

Slump in oil & gas industry to negatively impact market

A new report released by Transparency Market Research projects that the global valve market will exhibit a compound annual growth rate (CAGR) of 5.6 percent from 2016 to 2020 in terms of revenue. If the number holds true, the market, which valued at $71.21 billion in 2015, is expected to rise to $92.65 billion by 2020. In terms of volume, the market is expected to grow at a CAGR of 4.6 percent during the forecast period.

The global oil and gas industry is one of the key consumers of valves. The recent downturn witnessed by the global oil and gas industry owing to oversupply and reduced demand has had a huge impact on the growth of the valves market as well. Owing to the crash, which is considered one of the toughest seen by the industry in the past many decades, oil and gas companies have been cutting costs, wrapping up many ongoing projects, and investing in very few new projects. This is leading to a huge decline in the demand for a variety of valves.

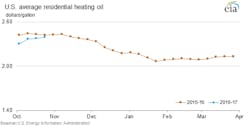

Heating oil expenditures expected to increase 38 percent this winter, but remain below normal

Graphic courtesy of the EIA

The U.S. Energy Information Administration‘s (EIA) recently released Winter Fuels Outlook projects that household heating expenditures and consumption will rise for all fuels compared with last year’s unusually mild winter. This is particularly true for households that rely primarily on heating oil, which comprise only 5 percent of households nationwide, but more than one-fifth of households located in the Northeast.

The EIA projects heating oil expenditures will increase by an average of $378 — or 38 percent — this winter compared to last winter, the largest increase of any fuel. The increase is the result of an expected rise in heating oil prices of 42 cents per gallon (20 percent), primarily due to higher oil prices, as well as a 15 percent increase in consumption, due to colder weather. Despite higher forecast expenditures compared with last year, household heating oil bills this winter are expected to be almost one-third lower than average expenditures over the five winters prior to last winter.

Shell divests noncore shale acreage in Western Canada

Royal Dutch Shell plc, through its affiliate Shell Canada Energy agreed to sell approximately 206,000 net acres of non-core oil and gas properties in Western Canada to Tourmaline Oil Corp., for a total consideration of approximately $1,037 million. The consideration is comprised of $758 million in cash and Tourmaline shares valued at $279 million. Subject to regulatory approvals the transaction is expected to close in the fourth quarter of 2016. The acreage includes 61,000 net acres in the Gundy area of Northeast British Columbia, Canada, and 145,000 net acres in the Deep Basin area of West Central Alberta, Canada. The assets are a combination of developed and undeveloped lands, along with related infrastructure, producing 24,850 barrels of oil equivalent per day of dry gas and liquids.