The market for ultrasonic flowmeters is among the fastest growing globally, as many end-users replace traditional metering devices with ultrasonic systems. There is, in particular, a great deal of attention being paid to ultrasonic flowmeters for liquid and natural gas custody-transfer applications. In fact, the market for ultrasonic meters for custody transfer of natural gas is one of the fastest growing niches within the entire flowmeter market.

The market for ultrasonic custody-transfer measurement is growing at approximately the same rate as the market for multiphase custody-transfer measurement. Coriolis flowmeters trail ultrasonic slightly, although the advent of large-line size Coriolis meters is having an impact on this market.

In response to the growing demand for ultrasonic systems, manufacturers are investing a lot of research and development in this area, perhaps at the expense of other meters, such as vortex and turbine. Suppliers have made significant progress in enhancing the accuracy and reliability of ultrasonic flowmeters—in part by increasing the number of paths and, thus, the number of measurement points, and also by adding greater diagnostic capability. Suppliers tout enhanced diagnostics as way to reduce the need for upstream piping and to better determine sources of error. Lately, new and more accurate meters have been developed for custody transfer of petroleum liquids, as well as for custody-transfer of natural gas.

Appreciating the Advantages and Improvements

Ultrasonic flowmeters have been gaining acceptance over the last 10 years as end-users come to understand and appreciate the technology—although some end-users are just now discovering the advantages and potential of ultrasonic flow measurement.

Advantages of ultrasonic flowmeters include high accuracy, high reliability, long service life, high turndown ratios, relatively low cost, low maintenance, no moving parts, valuable diagnostics, and redundancy capabilities. Clamp-on ultrasonic flowmeters, in particular, can offer redundancy by providing an easy check of an inline meter.

In addition to the traditional advantages, suppliers are significantly improving accuracy, sensitivity, and reliability. Energy, including energy conservation, and other markets have the potential to create even more demand, particularly as the technology improves to enable new applications. There is also an expansion in the usage of non-contact flow measurement.

Average ultrasonic prices are holding their own or even declining, which adds to their appeal. In comparison, the average price for Coriolis flowmeters is rising due to the recent introductions of large-line size models in the 10-inch to 16-inch diameter range. While the price for ultrasonic custody-transfer flowmeters remains high, it is still significantly less than the price of comparable Coriolis flowmeters for custody transfer.

Acceptance as the Highest Accuracy Gas Technology

Ultrasonic flowmeters have become accepted as the highest accuracy technology for gas, and acceptance for liquids is following suit. Some users trust ultrasonic flowmeters so much that they will use them with limited or no on-site proving. The acceleration in trust for gas ultrasonic meters began following U.S. approvals for their use in custody transfer of natural gas in 1998.

As Coriolis suppliers have begun releasing larger line size meters (up to 16 inches), they are generating some competition for ultrasonic flowmeters in the oil & gas segment. And while they cannot compete with ultrasonic meters that measure gas flow in pipelines from 20 inches and up, they may take some market share from ultrasonic meters in the 6- to 16-inch line sizes.

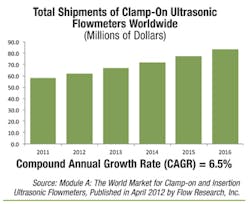

Growth in the Clamp-On Ultrasonic Flowmeter Market

While much of the attention to ultrasonic flowmeters had been based on progress in inline or “spoolpiece” meters, suppliers have also made important strides in clamp-on ultrasonic flowmeters. Clamp-on flowmeters have certain advantages over inline and insertion meters:

- They are portable, and thus can be used at multiple locations and to measure flow in different pipes.

- They are completely nonintrusive, since the transducers sit outside the pipe and do not penetrate it. This completely eliminates any possibility of pressure drop or flow disturbance.

- Clamp-on meters are also typically lower in cost than inline meters, since there is no meter body to pay for.

- Despite their advantages, clamp-on meters also have some disadvantages:

- Their signal passes through the pipe wall, which can attenuate the signal.

- The width of the pipe wall is sometimes an unknown factor that can have an impact on the accuracy of the measurement.

- The material from which the pipe wall is made can also have an impact on the ultrasonic signal, thereby affecting accuracy and reliability.

- Clamp-on meters tend not to be as accurate as inline meters, and they are not approved for custody transfer.

- Clamp-on meters need to be installed at the correct location on the pipe in order to work properly. While every meter needs to be installed properly, some are easier to install properly than others. Because there is more variability in the location of clamp-on than inline meters, they may be more difficult to install correctly.

Some suppliers have attempted to meet these difficulties by the use of tools to measure pipe thickness. Others, such as Siemens, have introduced clamp-on meters already mounted onto a spoolpiece so that pipe wall thickness and material is already taken into account. Despite these improvements, it is safe to say that inline meters are, generally speaking, more accurate and reliable than clamp-on meters, but that clamp-on meters have the advantage of lower cost and greater portability.

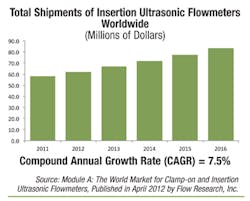

Insertion ultrasonic meters are also widely used for flare and stack gas applications. There is a growing need for this measurement worldwide, due to environmental considerations. However, ultrasonic meters compete with thermal meters and differential-pressure (DP) flowmeters with averaging Pitot tubes for these applications. Ultrasonic meters for flare and stack gas applications often sell in the $20,000 price range.

Insertion meters are also used in process pipes where they are installed by drilling a hole in the pipe and inserting ultrasonic transducers. While this form of measurement often does not achieve the same accuracy level as an inline or “spoolpiece” meter, it does have a cost advantage since the cost of the meter body is avoided. Insertion meters also have an advantage over clamp-on meters since their signal does not have to go through a pipe wall. This eliminates uncertainties that sometimes bedevil clamp-on meters involving wall thickness or the material of construction of the pipe wall.

A Role for All to Play

A great deal of research and development is currently going into multipath ultrasonic flowmeters for custody transfer of gas and liquids. This is resulting in greater growth in this market, as suppliers increase the accuracy, reliability and diagnostic capabilities of these inline meters. At the same time, important improvements are occurring among clamp-on and insertion flowmeters. Look for more improvements in all three technologies as the ultrasonic flowmeter market continues to expand.

Jesse Yoder, Ph.D., is president of Flow Research Inc. in Wakefield, Mass., a company he founded in 1998. He has 24 years of experience as an analyst and writer in process control. Dr. Yoder can be reached at [email protected].

For more information on Flow Research’s research in the area of ultrasonic flow measurement, see www.FlowUltrasonic.com.