By contrast, McIlvaine reports two-thirds of the capacity is fitted with scrubbers to remove acid gases such as SO2.There are 200 power boilers at 100 plants in China that have installed Selective Catalytic Reduction systems (SCR), according to McIlvaine. These power plants are mainly located in the population centers of Beijing, Guangdong, Zhejiang, Jiangsu, Shanghai, Fujian, Shanxi, etc. Only four power plants have installed the less efficient but cheaper Selective Non-Catalytic Reduction (SNCR) systems. All boilers installed since 2003 are equipped with Low NOx burners.

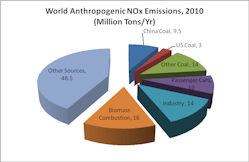

McIlvaine says the NOx emissions from Chinese coal-fired power plants were 9.5 million tons in 2010. This compares to three million tons of emissions from U.S. power plants. Japan, South Korea, Taiwan and all of Europe have higher percentages of NOx control on power plants than the United States. The result is that the Chinese and U.S. coal-fired power plants together emit almost as much NOx as the coal plants in the rest of the world combined.

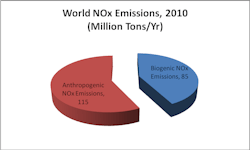

Man-made or anthropogenic emissions account for 57 percent of the total, according to McIlvaine. Chinese power plants emit 8.2 percent of the world’s anthropogenic NOx. Chinese power plants emit as much NOx as all the passenger cars in the world. India and other Asian countries are planning large numbers of new coal-fired power plants, notes McIlvaine, so the percentage contribution of China and the United States figures to shrink.

The market is served by a mix of Chinese and international companies. Initially all the technology came from outside of China. Now there are a number of experienced system vendors, including CPI Yuanda, Fujian Longjin, Beijing Guodian China Datang, Shanghai Electric and nine other significant suppliers.

There is rapidly growing catalyst manufacturing capability, according to McIlvaine. It started with KWH of Germany transferring operations to Sichuan in 2004. A number of other facilities are now in operation. Cormetech of the U.S is partnering with China Chongqing Yuanda and operates a 10,000 M3/yr catalyst facility in Chongqing.

Catalyst regeneration and replacement is presently very small market in China because most installations are less than five years old. However, in the longer term, China will offer the largest regeneration and replacement market. Through 2020, the United States will be the largest catalyst replacement and regeneration market, according to McIlvaine. Since most international catalyst manufacturers are working at near capacity and the domestic capacity is raising, the potential for import of catalyst to China is expected to diminish.