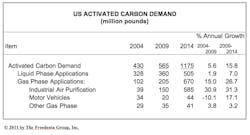

Demand for activated carbon in mercury control applications alone is forecast to grow more than fivefold to 520 million pounds, according to a report by the Freedonia Group. An activated carbon injection (ACI) system used for mercury control in a large industrial facility can consume up to two million pounds of activated carbon annually. As a result, Freedonia says the enactment of even a portion of the emissions standards currently in draft form will represent a tremendous growth opportunity for U.S. suppliers.

Since powdered activated carbon (PAC) is overwhelmingly the product type used in mercury control technology, the PAC segment will expand to account for two-thirds of US product demand in 2014 in volume terms. Granular activated carbon (GAC) types will see strong gains through 2014 as well, due primarily to expanded use of activated carbon filter systems in municipal drinking water treatment.

In addition to the rapid gains underway in the industrial air purification market, demand for activated carbon in gas phase applications will improve in the motor vehicle segment, according to Freedonia. Activated carbon will see modest growth in liquid phase applications other than drinking water treatment, such as the preparation of pharmaceuticals.

In regional terms, Freedonia says demand for activated carbon will be strongest in the South and Midwest, where above-average concentrations of coal-fired power plants, clinker cement plants, and other facilities with large industrial boilers will create substantial markets for activated carbon used in mercury control technology. The South will also see the largest gains in the drinking water treatment market through 2014 as Southern municipalities rely strongly on surface-water sources for their drinking water supplies.