A turnaround (TAR) can be one of the most difficult events for an operating plant to conduct. Most continuous processes run without interruption, leaving little opportunity for routine maintenance on critical equipment, especially if entire systems need to be isolated to complete work. The combination of cyclical repairs, equipment inspections, product changeover and capital projects can have a resounding effect on a company’s bottom line. Although taking a plant or production unit out of service for a short period of time to optimize productivity in the long run may be inconvenient, it is necessary to maintain continuity and optimal productivity. These highly complex events require significant capital expenditure and, since any plant downtime represents a loss of revenue, the incentive to stay on schedule is high.

Executing a perfect TAR is an extraordinarily difficult feat. As highlighted in Figure 1, the juggling of scope, process, planning and scheduling as well as many other factors all impact a turnaround’s cost and duration. A turnaround optimization program (TOP) is the only way for a company to successfully handle all the event’s components and prevent serious financial setbacks. This article outlines a TOP plan to help management limit expenditures, conduct a TAR event with the leanest maintenance possible and be back to maximum production in the shortest time possible.

Setting a worklist

The optimization program begins with forming a specifically designated TAR team that consists of stakeholders from every relevant department. The team’s first task is to conduct an analysis to identify the work necessary during the turnaround and define project goals. Because this group of workers is comprised of a variety of professions, it will be better equipped to choose the best option from a wide pool of opinions and viewpoints. Since it will also be responsible for developing the scope and framework for the turnaround timetable, the group’s diverse experience is an important factor that will help it move toward success.

Considering work performed during a TAR costs three to four times as much as work performed during regular operating times, each item proposed for a TAR scope registry needs to be scrutinized and debated among the team members. Only absolutely necessary improvements, capital projects and tasks essential to keep the plant operating efficiently should be included. A tight worklist is especially important at this stage because the backlog will almost certainly expand as the shutdown takes place – 90 percent of outages have a scope creep between 10 and 15 percent. These uncontrollable additions grow the project’s overall goal and should be avoided because they threaten to knock other essential tasks off the ticket so the project can stay on schedule. Ultimately, increasing the scope could negatively affect operational performance once the equipment is returned to service.

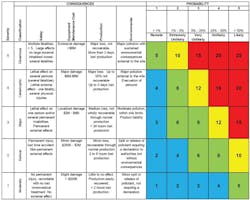

To avoid scope creep and properly evaluate which tasks deserve to be on the exclusive turnaround list, the team can utilize prioritization tools such as the criticality matrix (see Figure 2) to graphically rank tasks by importance. To use the matrix, members of the TAR team need to follow a thoroughly explained, agreed-upon assessment standard. In this particular example, a task ranked 15 or higher is classified as most critical, with those scoring five to nine slightly less important and lower levels considered secondary work. Proper scope management can have a 20 to 25 percent benefit to overall turnaround success. Once the TAR team has prioritized the work, it can create an organized maintenance activity timetable.

Figure 2. Criticality matrix

Project implementation

Developing the scope is essentially strategic planning, but it only provides a rough, vague overview of what needs to be done and does not delve into the particulars. The next step is for the TAR team to determine the specific maintenance activity timetable in the form of a detailed plan. By using agreed-upon site planning standards, the group should now create a step-by-step approach using the best execution estimates to complete the worklist and stay true to upcoming budget and duration targets.

Once the plan is in place, managers will delegate the tasks to the appropriate team members. This can become overwhelming if not handled properly because of the complex nature of turnarounds; The targets and milestones will likely be extensive. Management should assign team members responsibilities in accordance with their personal levels of expertise, knowledge, skills and experience. All TAR participants, especially managers and supervisors, should develop certain levels of accountability. Involving all team members in all aspects of the TAR process will help everyone understand their roles and responsibilities and build their skills to better handle these inevitably reoccurring, albeit infrequent, projects. Filling the appropriate positions with the right employees is crucial for the turnaround coordinators – who are in charge of overseeing the planning and execution of maintenance activities for each operational unit – to manage the flow of work.

As the project goes forward and resources are mobilized and managed throughout the planning and execution process, all activities should be monitored to confirm they meet efficiency and environmental requirements. Gathering sufficient strategic data is an important step to address risk and make the best possible decisions to maximize the potential for success. The TAR team should be able to provide exact records on how the project is developing by using key performance indicators (KPIs) that specifically track front-end loading (FEL) activity. Tracking and recording these FEL procedures will also aid in preproject planning the next time around. With the help of these metrics, decision makers can better control project performance and focus on areas that may need improvement. In addition to this data, the TAR team should organize a daily team meeting to report progress and act as a value-added communication platform between departments.

Figure 3. Deming cycle

It is important to remember that a TAR is not complete when the work packages are finished, but when the plant is back online. However, after all the adaptations the event will likely experience, the plant’s startup procedure will need to be reviewed a final time. Any work performed on equipment not originally included in the scope could have altered the recommission plan. To finish TAR execution, the operations and process engineering departments will need to review, revise and assess the risk of the procedure to prevent injury, spills and damage to equipment.

Sustainable improvement

In the final step in the TAR optimization program, after the plant is successfully back online, the TAR team from all departments will reflect on what was done well and what was not to improve for the next shutdown. All maintenance activities should make a habit of planning, executing, reflecting, improving and planning again, as highlighted in the Deming cycle (see Figure 3). This ritual is not exclusive to individual tasks but also applies to a site’s overall periodic shutdown routine. Discussing the data will help the team get the full picture of how the project turned out and identify ways to implement continuous improvement measures. For this meeting, companies may find inviting a facilitator from outside the organization can help control the flow of information and prevent finger-pointing.

Even though a TAR may be executed safely, efficiently and on schedule, an opportunity to optimize turnaround disciplines and practices will always exist. Tasks must be coordinated better, delays mitigated, the schedule adhered to and progress reporting accurate. By developing an effective process to help facilitate the shift from oversight to driving performance, managers can enforce proactivity, increase performance and have successful TARs with short- and long-term benefits.

Lee Williamson is a consultant at T.A. Cook Consultants in North America. With more than 25 years of manufacturing experience in the chemical industry, Williamson focuses on planning and managing large-scale projects and turnaround maintenance.