Trace gas detection, the ability to detect a scant quantity of a particular molecule — a whiff of formaldehyde or a hint of acetone — in a vast sea of others, underlies many important applications, from medical tests to air pollution detectors to bomb sniffers. Now, a sensor recently developed* at the National Institute of Standards and Technology (NIST) that is hundreds of times faster and more sensitive than other similar technologies may make such detectors portable, economical and fast enough to be used everywhere.

According to the NIST investigators, the new sensor overcomes many of the difficulties associated with trace gas detection, a technique also used widely in industry to measure contaminants and ensure quality in manufacturing. A trace level of a particular gas can indicate a problem exists nearby, but many sensors are only able to spot a specific type of gas, and some only after a long time spent analyzing a sample. The NIST sensor, however, works quickly and efficiently.

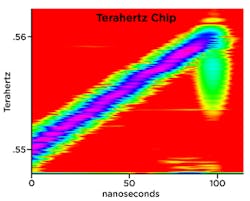

A major hurdle the new technology overcomes is that it is now possible to look at nearly all possible gas molecules instantly using terahertz frequencies. Previously, it was necessary to expose molecules to a vast range of terahertz frequencies — slowly, one after another. Because no technology existed that could run through the entire frequency band quickly and easily, the NIST team had to teach their off-the-shelf equipment to “chirp.”

The NIST team has applied for a patent on its creation, which can plug into a power outlet and should be robust enough to survive in a real-world working environment.