The oil and gas industry heads into the third quarter of a year that has, so far, continued in line with the overarching sentiment of 2016: uncertainty. Conditions remain challenging, and the industry is learning to adapt to what many have called a ‘new normal’ – maximizing profits through increasing rationalization at every stage of the drilling, exploration and transport process.

For suppliers, this presents an opportunity to work with customers to ensure they get the most out of the equipment delivered. It is no longer enough for suppliers to play a passive role – They are increasingly expected to, and they see the need to, work with customers to provide a collaborative approach. This involves helping customers from the beginning of a project to understand the nature of the often-challenging environments in which products will function, helping to select the most appropriate option and maintaining the product throughout its life cycle.

This attitude is borne out by recent research. In a survey of oil professionals by Trelleborg’s Oil and Marine operation, “quality and durability” was listed as “vital” more than 80 percent of the time, while “price” was listed as vital only 19 percent of the time. The next most “vital” factors were “aftersales support and service,” and “ease of installation” at 32 and 28 percent, respectively. In a separate survey from Trelleborg’s Offshore operation, 61 percent of facilities surveyed indicated they would be willing to spend more on a project upfront to ensure longevity and reduce the need for future upgrades.

These findings show a significant attitudinal shift in an industry that can often be resistant to change, especially when viewed in the context of the aforementioned uncertain sentiment in the market. The industry realizes that it now makes sense to invest in long-term solutions to the challenges of rationalization, and part of this is investing in the supplier relationship. Nowhere is this more crucial than in the field of oil transfer, in which pressure to work quickly and efficiently is intense, but must function without endangering the safety of those working on the project or the environment in which transfer occurs.

Connection of hoses with hydraulic wrenches. All images courtesy of Trelleborg Oil & Marine

Help find the right solution

One of the most valuable ways suppliers can help their customers is by ensuring they select the right product for the job.

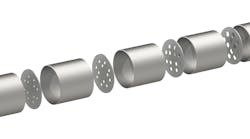

In most cases, the suitable solution for nonharsh, low-cost extraction environments is a single- or double-carcass nipple hose. The manufacture consists of using binding steel wires fixed on the nipple flange to block the hose body structure made with textile layers, reinforced by a steel helix. The standard nature of this design means that this type of hose is the most commonly used one in today’s market, in floating and submarine configurations.

However, in more challenging environments or situations where particularly long service life is required, it is necessary to use a nippleless hose. A nippleless hose does not have a stiff metal connector that reduces flexibility, and instead carries a flange embedded in the rubber itself. This reinforced flange design combined with an integrated bending stiffener can be optimized for reeling, and can therefore be used with reel systems that have a smaller drum diameter.

To help customers select the most suitable solution, hose suppliers can assist in the first instance by carefully analyzing the environments in which their products will function. It is increasingly vital for research and development (R&D) teams to get involved at the earliest stage of any project to accurately simulate the environment in which a hose will function and predict how it will behave.

In conducting these analyses, R&D teams usually begin by using prototypes, which undergo rigorous chemical and mechanical testing in addition to hydrodynamic analysis. This allows the creation of models that match real-life service conditions while granting researchers a detailed analysis of performance under fatigue. This process varies according to whether the product in question is a qualified hose designed to meet GMPHOM 2009 requirements or customized according to API Spec 17K. If API Spec 17K is selected, high fidelity finite element (FEM) and finite element analysis (FEA) models for each specific hose construction are created, enabling precise prediction of hose behavior, including specific characteristics and limitations.

Following this, the fluid properties of the product to be transferred, including temperature, pressure and viscosity – as well as the necessary standards and their specific requirements – are all scrutinized under hydrodynamic analysis (static, dynamic and extreme). This allows for a detailed comparison report on the limitations of each hose to be developed. Because the number of off-loadings will also affect the strain placed on the hose – particularly in more extreme environments – nippleless hoses, more commonly used in these conditions, are also tested against stress and strain databases for fatigue analysis, which is mandatory under API Spec 17K Standard. For hoses qualified to GMPHOM 2009 standards, a hydrodynamic analysis is conducted as necessary, taking into account how a qualified hose design will function in conjunction with its specific properties, performance expectations and the environment in which it will function.

Once this initial analysis is complete, other objects in the environment in which the product functions must be considered. Ease of installation is a top requirement for customers selecting an oil transfer solution, and hoses should be specifically engineered so they are easy to install with minimal requirements for the management of integration with other systems. Integrating hoses with other installation technology such as marine breakaway couplings, reeling apparatus or quick emergency release devices is also essential to ensure safety.

When the situation in which a hose will be used is fully analyzed, a recommendation can be made as to the most appropriate solution to use. But the role of the supplier should not end there.

Stay committed

Once equipment is selected and in place, suppliers must support projects throughout their execution to ensure the highest safety standards are upheld, as well as guaranteeing the benefits of proper life cycle management.

Manufacturers can ensure safety by advising customers on best practices for storing and handling hoses. Rubber can be sensitive to elements such as ozone, ultraviolet rays, humidity and heat, meaning storage must follow a few simple rules to protect the product against aging.

To stay competitive, suppliers need to offer more than just quality products; Buyers need to know suppliers invest in relationships with reliable partners who will support them throughout the life cycle of a project, and using their expertise will help them face up to an uncertain future.

Nicolas Landriere is product manager and Vincent Lagarrigue is PA oil & marine director for Trelleborg Oil and Marine.