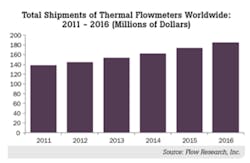

Thermal flowmeters came onto the market in the mid-1970s, not long after Coriolis flowmeters. While the worldwide market for Coriolis flowmeters now exceeds $1 billion, the market for thermal flowmeters is under $150 million. Faced with such a wide difference in market share, one might wonder why the Coriolis flowmeter market has developed so rapidly, while the thermal flowmeter market has developed more slowly.

To answer this question, it is important to understand some important differences between Coriolis and thermal flowmeters. Coriolis meters, for example, measure both liquids and gases, while the vast majority of thermal flowmeters measure gases.

Coriolis flowmeters also have a high degree of accuracy; in fact, they are the most accurate meter made. As a result, they are used for custody transfer of both of petroleum liquids and gases. Thermal flowmeters, by contrast, typically have accuracies in the 1–4 percent range, which is not sufficient for custody transfer. So while thermal flowmeter are used for a variety of gas applications, they are not yet used for custody transfer.

Finally, Coriolis flowmeters have received approvals from the American Gas Association (AGA) and the American Petroleum Institute (API) for use in custody transfer of both natural gas and petroleum liquids. This has greatly benefited Coriolis meters since custody-transfer applications are growing rapidly, particularly in the energy sector. The world’s increased need for natural gas and hydrocarbon liquids has generated rapid growth in custody-transfer measurement of these fluids.

Regardless of the market size, the thermal flowmeter category is responsible for some compelling technology innovations, which began with their introduction to the marketplace in the 1970s and continues to this day.

RELATED: A New Paradigm for Thermal Dispersion Mass Flowmeters

How It All Started

The history of thermal flowmeters is fascinating. Thermal flowmeters were born on the West Coast of the United States—the result of independent development by first two, then three separate companies. One company was Fluid Components International, which began by developing thermal flow switches that were used in the oil patch. The switches detected the movement of oil in oil well pipes, but they didn’t actually evolve into actual flowmeters until 1981.

While Olin and Kurz were doing research using anemometers, they were more interested in developing measurement products for industrial environments. This would require a more rugged device than an anemometer. They approached TSI about developing industrial products, but TSI wasn’t interested. As a result, Olin and Kurz decided to start their own company, incorporating Sierra Instruments (www.sierrainstruments.com) in Minnesota in 1973. In 1975, they moved the company to California, packing the business up into two trucks, driving it across the Continental Divide to set up shop in Monterey.

In 1977, Sierra Instruments was making both air sampling products and thermal flowmeters. That year, Jerry Kurz decided to become independent and formed Kurz Instruments. Sierra kept the air sampling products, while Kurz Instruments kept the thermal flowmeters. However, Sierra got back into the flowmeter market in 1983.

In the early 1980s, Sierra, Kurz, and Fluid Components were the only companies manufacturing thermal flowmeters. However, over time, more thermal flowmeter manufacturers arrived in the area of Monterey. These include Eldridge Products, Fox Thermal Instruments, and Sage Metering Inc.. These companies are largely offshoots of Sierra and Kurz. Eventually, some of the larger flowmeter companies entered the market, including Endress+Hauser and ABB. Magnetrol, a manufacturer of level and flow switches, also entered the thermal flowmeter market.

How They Work

Thermal Flowmeter Suppliers| ABB | www.abb.com |

| Delta M | www.deltamcorp.com |

| Eldridge Products | www.epiflow.com |

| E+E Elektronik | www.epulse.com |

| Endress+Hauser | www.us.endress.com |

| Fluid Components Intl. | www.fluidcomponents.com |

| Fox Thermal Instruments | www.foxthermalinstruments.com |

| Hontzsch | www.hontzsch.com |

| Intek | www.intekflow.com |

| KEM Kueppers Elektromechanik | www.kem-kueppers.com |

| Kurz Instruments | www.kurz-instruments.com |

| Magnetrol International | www.magnetrol.com |

| Sage Metering | www.sagemetering.com |

| Sierra Instruments | www.sierrainstruments.com |

| Thermal Instrument Co. | www.thermalinstrument.com |

| Tokyo Keiso | www.tokyokeiso.com |

| VP Instruments | www.vpinstruments.com |

This information was abstracted from Flow Research’s Worldflow Handbook. For more information about this 122-page guide to the worldwide flowmeter market, visit www.flowhandbook.com.

Thermal flowmeters are used almost exclusively to measure gas flow. They introduce heat into the flowstream, and measure the rate of heat dissipation. The heat dissipation is measured by one or more temperature sensors. This method works best with gas flow because the much greater heat absorption capacity of liquids rapidly saturates the signal, leading to a loss of measurement resolution.

While all thermal flowmeters inject heat into the flowstream, there are two different methods used to measure the rate of heat dissipation. One method is called constant temperature differential. Thermal flowmeters using this method utilize a heated RTD as a velocity sensor and another sensor that measures the temperature of the gas. The flowmeter attempts to maintain a constant difference in temperature between the two sensors. Mass flowrate is computed based on the amount of electrical power added to heat the velocity sensor to maintain this constant difference in temperature.

The second method is called constant current. It also uses a heated RTD as a velocity sensor and another temperature sensor to measure the temperature of the flowstream. With this method, the power to the heated sensor is kept constant. Mass flow is computed based on the difference in temperature between the heated velocity sensor and the temperature of the flowstream. Both methods make use of the principle that higher velocity flows produce a greater cooling effect. And both methods measure mass flow based on measuring the amount of cooling that occurs in the flowstream.

Environmental Applications Drive the Market

Thermal flowmeters are used for a wide variety of applications. However, there are two periods in the history of thermal meters when environmental applications have boosted sales. The first period was in the early 1990s, when the need for continuous emissions monitoring (CEMS) required measurement of sulfur dioxide (SO2) and nitrous oxides (NOX). Thermal flowmeters were ideal for this purpose. By combining a measurement of the concentration of SO2 and NOX with a measurement of flowrate, it can be determined how much of these gases are released into the atmosphere. This is important since they have been identified as the primary causes of acid rain. At that time, thermal flowmeters competed with averaging Pitot tubes and ultrasonic flowmeters to make this measurement.

The broad acceptance of global warming as scientific fact rather than as mere theory has presented a second opportunity for thermal flowmeters. Beginning with the election of the Obama administration in 2008, the U.S. government has made the identification and reduction of greenhouse gases a major priority. For example, the Obama administration has the stated goal of reducing greenhouse gas emissions by 80 percent by 2050.

Other countries have also joined in the effort to reduce greenhouse gases. The Kyoto Accord has resulted in the creation of several mechanisms for measurement of greenhouses gases internationally. These include Certified Emission Reductions (CER), a credit system designed to help European countries achieve reduced emission targets. A second program is the Clean Development Mechanism, which allows countries to help reduce emissions in developing countries by investing in sustainable development programs that have that result.

Some of the applications that have opened up as a result of efforts to reduce greenhouse gases include the following:

- Biomass gasification

- Ethanol distillation and refining

- Recovery of methane from coal mines

- Measuring emissions from boilers, process heaters, and steam generators

- Measurement of recovery of landfill gases

- Measurement and monitoring of flue gases and flare gases

Product Innovations Abound in Thermal Flowmeters

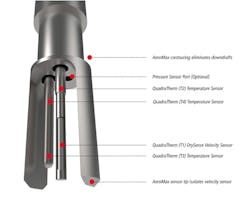

Thermal flowmeters are still a relatively new technology, and suppliers have responded to the sheer volume of new and challenging applications by introducing a wide range of important product improvements. Sierra Instruments has made such a step forward with its new QuadraTherm flowmeter. What has not previously been accounted for by thermal flowmeter companies is that some of the heat added to the flowstream by the heated temperature sensor is lost in several ways:

- Through radiation

- From "stem conduction," which is heat conducted up the probe shaft

- End loss of heat from the end of the sensor

- Natural convection

- Forced convection

Sierra actually measures this previously unaccounted for heat loss by placing two additional temperature sensors in the flowstream (Figure 1).

The QuadraTherm uses two temperature sensors to accurately measure heat dissipation not registered by other meters; this is in addition to the heated velocity and temperature sensors that measure mass flow like other meters.

The biggest payoff in this new design is enhanced accuracy. According to Sierra, the QuadraTherm has accuracy of 0.5 percent of reading when measuring above 50 percent of full scale flow. This accuracy level is for inline meters, while insertion meters achieve parallel accuracy of 0.75 percent. The QuadraTherm also features on-board in-situ diagnostics for field calibration verification, has multiple gas capability, and the insertion version can be used on different pipe sizes.

The QuadraTherm addresses one of the major issues that has limited the rate of growth of thermal meters—i.e., their limited accuracy. An accuracy level of 0.5 percent reading for gas measurement actually approximates that of Coriolis for gas. This means that, at least in theory, the QuadraTherm should be able to be used for custody transfer. What it lacks is the approvals from the AGA and other regulatory bodies. These may come with time.

In addition to Sierra’s QuadraTherm meter, other thermal flowmeter companies have introduced new and innovative products. Fluid Components International, for example, has released several models in its ST100 Series that feature a "dual-element averaging system." These models have two sensors instead of one. The transmitter electronics average the input from the two independent sensors into a single output. This idea might be compared to the type of averaging done by a multipath ultrasonic meter or a multipoint averaging Pitot tube. The ST100 is also one of only three thermal products to receive Safety Integrity Level (SIL) compliance.

Magnetrol’s Enhanced Model TA2 thermal mass flowmeter is another innovative product in this category. Designed for both air and gas applications, the Enhanced TA2 measures flowrates as high as 50,000 standard feet per minute (SFPM) for air. Like other thermal flowmeters, it has especially good sensitivity at low flowrates, along with high turndown rates. Another important feature is a field calibration verification procedure that does not require the purchase of external hardware. Among the applications for the Enhanced TA2 are measuring compressed air, natural gas, digester/biogas, and combustion air.

Other notable recent product developments in the thermal category include Fox Thermal Instruments FT3 thermal mass flowmeter and temperature transmitter, which features in-situ calibration validation, and Sage Metering’s Sage Rio thermal mass flowmeter, which is Class 1, Division 1 hazardous-area approved and features in-situ calibration verification as well.

More Growth & More Feature-Rich Products

The thermal flowmeter market is continuing to get a boost from the drive to measure greenhouse gas emissions, as well as other energy management applications. As a result, suppliers are responding with more feature-rich products that have enhanced performance levels. While the total market size still remains small relative to some other technologies, this market is poised for some very rapid growth. While thermal meters may never be as widely used as Coriolis meters, they have their own niche and set of applications. Competition in the market is increasing as suppliers introduce better performing products. This is a situation where end-users win. Look for more growth and more high-performance products to continue to emerge in this market.

Jesse Yoder, Ph.D., is president of Flow Research Inc. in Wakefield, Mass., a company he founded in 1998. He has 25 years of experience as an analyst and writer in process control. Dr. Yoder specializes in flowmeters and other field devices, including pressure and temperature products. Dr. Yoder can be reached at [email protected].

For more information about Flow Research’s coverage of the thermal flowmeter market, visit www.flowthermal.com.