Many process plants now have a network infrastructure in place to connect their wireless field instruments to gateways and, from the gateways, to a distributed control system (DCS) or other hosts. Conventional wired field instruments can join these wireless networks by using adapters, often increasing the number of connected instruments. Typical field instruments connected to wireless networks measure temperature, pressure, level, flow and other process parameters.

This infrastructure is usually designed to support hundreds or even thousands of field instruments, usually with multiple gateways. Systems of this size can be quite complex to design, install and maintain, although the benefits they provide more than justify the required efforts in most cases.

But what about those applications where wireless field networks are required but the number of instruments to be connected is 20 or fewer? Using the same types of wireless network hardware for these small applications as implemented in large installations can drive cost and complexity to an impractical level, so a better solution is needed.

The answer is to instead use wireless networks specifically designed for smaller applications. These types of networks cut cost and complexity to a level acceptable for these types of projects and can extend the number of applications where wireless field instrument networks are viable.

Before discussing the specifics of these small wireless networks, the following applications describe where they can be put to use.

Applications for small wireless field networks

Remote installations such as oil and gas well pads, water and wastewater pumping stations and others are often excellent candidates for small wireless networks. These remote installations usually have fewer than 20 wireless instruments and sometimes much less.

However, these instruments are often installed at a considerable distance from each other and from the local controller, typically a programmable logic controller (PLC) or a remote terminal unit (RTU). In other cases, new instruments need to be retrofitted to remote installations to improve operations, safety or regulatory compliance.

In either case, installing hardwiring from each instrument to the controller can be expensive and difficult. Wired fieldbuses such as HART and FOUNDATION Fieldbus are a solution used in many large process plants to minimize required field wiring, but these types of networks are complex and expensive to design, install and maintain. A better solution is a small wireless network, which eliminates the need to wire each instrument back to the controller.

Another application for small wireless networks is a temporary installation in an existing large process plant. These installations are often used to add points of measurement for nonregular operations such as startup, shutdown and maintenance turnaround where a plant is in a transitional state.

It is seldom practical to add wired instruments and connect each one back to the main control system for these temporary installations. It also does not make sense to add a wireless infrastructure capable of supporting thousands of instruments. The third option, adding new wireless instruments to an existing wireless infrastructure, is often not feasible because it may require the installation of new repeaters and gateways, along with reconfiguration of the network. Again, the best solution is a small wireless network designed specifically for these types of applications.

The process development labs and small pilot plants found in many process industries are another type of application where small wireless networks should be considered. These types of applications typically have mobile equipment, and equipment configuration and points of measurement frequently change, making them ideal candidates for wireless instruments. But as with the other two types of applications, it is seldom feasible to install a wireless network capable of supporting thousands of field instruments when there are just a few points of measurement.

The following examines how these networks are designed, installed and used.

Implementing a small wireless network

As mentioned, large wireless networks can be quite complex to design, install, connect and maintain. Small wireless networks simplify this procedure by eliminating one of the more time-consuming steps.

As shown in Figure 1, the steps required to design, install and connect a conventional large wireless network include:

- Delivery and installation of the wireless instruments and gateways

- Configuration of the instruments’ transmitters

- Configuration of the wireless gateway(s)

- Set up of the host system

Figure 1. Large wireless networks require four steps for design, installation and connection. Small wireless networks simplify the process by using preconfigured wireless transmitters and gateways.

With a small wireless network, step 2 is eliminated because the wireless instruments can be delivered preconfigured; however, this requires the use of instruments and a gateway from a single vendor, and there are a few limitations.

For example, one leading vendor offers a small wireless network with a gateway limited to 20 instruments — each with an update rate of two seconds or more. If a one-second update rate is required for each instrument, the maximum number of instruments drops to 10.

A second limitation is the ability to connect to only one host system instead of to multiple host systems as with most large wireless networks. This limitation can be address by connecting other systems to the host system.

A third limitation is the 20-meter maximum distance between the host system and the gateway, although this distance can be extended to 1.2 kilometers as shown in the application example in the following section.

The maximum distance from the gateway to each instrument is typically 500 meters with line-of-sight — the same as with a standard ISA 100 Wireless system, which is more than sufficient for most small wireless systems.

Figure 2 shows how a small wireless network is normally installed. The field wireless devices or instruments are shown on the lower right, and they communicate via an ISA 100 Wireless network to the palm-sized gateway, labeled FN110.

Figure 2. The field wireless devices and the FN110 gateway module are delivered preconfigured, and wireless communications are automatically established as soon as they are powered up.

The FN110 consumes just 0.3 watts, and when used with a PLC/RTU such as Yokogawa’s STARDOM with low power requirements, the combination can easily operate from a power source supplied by solar panels and a battery. This allows deployment of a monitoring system where a separate source of power is not available.

The gateway is hardwired to the LN90, which consists of an interface adapter, a RS-485 signal relay and power supply for the FN110 gateway module. The LN90 communicates to a single host system via a point-to-point Modbus serial link. The host is normally a PLC or an RTU, and Modbus is the most widely supported protocol by these types of hosts.

Application example: Well pad in oil and gas field

Sometimes, data from additional instruments may not be needed by a local controller but required by another host, such as a data acquisition system. For example, a well pad in an oil and gas field may need to collect and store data related to production outflows. This can be an ideal application for a small wireless system acting independently of the local control system.

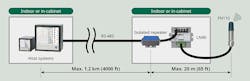

As previously mentioned, communication distance from the gateway to the host system is typically limited to 20 meters. But as shown in Figure 3, this distance can be increased to 1.2 kilometers by installing an isolated repeater.

In this example, the FN110 gateway module is installed outdoors and communicates with up to 20 wireless instruments. The gateway’s degree of protection is IP66/67, or Type 4X, so it is suitable for outdoor installation and can operate in a temperature range from minus 40°C to plus 70°C (minus 40°F to plus 158°F). Most wireless instruments have similar operating specifications, making the entire installation suitable for installation in harsh and corrosive environments, such as a well pad in an oil or gas field.

The gateway is hardwired to the LN90 protocol translation device, which connects to the isolated repeater. The repeater connects to the host system, which, in this case, is one of the two data acquisition systems shown in Figure 3.

Figure 3. Small wireless networks can use an isolated repeater to extend communication distances from the protocol translator to the host from 20 meters to 1.2 kilometers.

These systems allow data to be collected, stored and displayed locally. If desired, each can be connected to other systems via hardwired digital data links.

Conclusion

Large wireless networks are a good fit for most process plants but are often overkill for smaller applications with 20 field instruments or less. In these scenarios, it is simpler and less costly to use a small wireless network designed specifically for these types of applications.

Small wireless networks provide simplification by preconfiguring the wireless field instruments, eliminating one of the four main steps required to configure, install and connect a wireless system. The main tradeoff is a limit on the number of instruments, but this is usually not a concern for the small installations where these networks are used.

Kinichi Kitano is a senior engineer in Yokogawa’s New Field Development Center. He completed a master’s in engineering from Kyoto University with a specialty in control theory. Previous responsibilities with the company include DCS design and implementation, fieldbus technologies and wireless networking.