Because of a continually rising demand for hydrocarbons, the exploration of offshore oil and gas has moved past shallow reservoirs to even greater depths. As such, deepwater subsea production systems must now go deeper and reach further than ever before to extract more oil and gas from harsher stores in new locations around the world. As exploration and drilling go deeper, the need to reduce the risk of the uncontrolled release of formation fluids throughout the life cycle of a well is paramount.

The risks associated with annular pressure buildup between the oil well casings cannot be ignored. Looking at the evolving market for well integrity, this article reviews how preventing excessive overpressure can protect the steel casing and reduce unplanned downtime.

Under pressure

Annular pressure buildup (APB) refers to pressure increase caused by temperature changes in the wellbore that takes place during the normal production life of deepwater wells or in worst-case discharge conditions. It occurs when the heat generated during production increases the temperature of the fluids confined within the annular spaces of the casings. This increase in temperature will result in the volumetric expansion of fluids and consequently, pressure increase, because they are within a sealed annulus. The temperature will vary over the life of the well as a function of the flow rate and fluid composition.

On land, pressure can be relieved by opening the casing valve and venting the pressure to a tank, but this is not possible in deepwater wells. With no means for the fluid to vent, heat from normal drilling and production operations can cause the trapped fluids to expand. The resulting possible pressures of more than 10,000 psi can create a burst load on the outer casing and a collapse load on the inner casing.

If not managed properly, APB-induced loads can compromise well integrity during production operations. This could potentially lead to a fluid leak or a catastrophic rupture of the inner casing, halting production and shutting down operations.

Mitigation solutions

Over the last 20 years, a wide variety of APB mitigation techniques have been deployed to prevent APB from compromising well designs. The main mitigation solutions currently available include burst disks, collapse disks, nitrified spacers, open shoes, syntactic foam and vacuum-insulated tubing. These solutions can be broken down into two types of APB mitigation:

- Type-I mitigation techniques control APB by reducing heat loss from the production tubing to the wellbore, reducing APB in the annuli.

- Type-II mitigation techniques control APB by reducing annular stiffness (psi/°F) by modifying the annulus contents and wellbore boundaries or placing pressure regulating devices in the annulus.

Syntactic foam is classified as a Type-II mitigation technique and vacuum-insulated tubing is classified as a Type-I mitigation technique. While these innovative techniques have developed over time and helped expand the APB mitigation toolkit, selecting the proper mitigation technique is dependent on well, fluid and pipe characteristics.

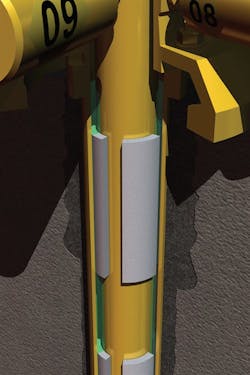

The most effective mitigation solutions for APB allow the fluid trapped within the casing annulus to expand. One such solution currently available is called crushable foam wrap (CFW), a collapsible material manufactured from a rigid polymeric material with a closed-cell, foam microstructure. Classified as a Type-II mitigation technique, CFW is a passive APB mitigation system specifically designed to collapse within a specified temperature and pressure envelope.

This collapsible barrier is typically installed on the casing’s outer wall within the B or C annuli of a subsea well before being immersed within the annulus fluid. This displaces the liquid in the casing annulus when the well is completed. When heat from drilling and production operations cause the trapped liquids to expand, the collapsible barrier acts as a mechanical fuse and collapses within a predetermined pressure and temperature envelope, allowing expansion of the annulus fluids and dissipation of any potentially hazardous pressure increases.

Installing a collapsible barrier in the casing annulus could prevent catastrophic failure from happening before any potentially dangerous pressure occurs.

Designed to collapse

CFW is designed to collapse within a narrowly specified temperature and pressure envelope, which defines the upper limits of pressure and temperature for the well. This increases the remaining volume in the annulus and facilitates a pressure reduction.

In the startup phase, the CFW remains intact with no significant volume change unless the temperature increases beyond the predetermined pressure and temperature collapse criteria. As the pressure and temperature in the well rise during operations, the materials begin to compress and relieve pressure in the narrow, confined space of the annulus. If conditions reach certain preset limits, the CFW undergoes a progressive and significant collapse, preventing excessive overpressure and thus protecting the steel casing from failure.

The crush mechanism occurs well before the casing collapse pressure, preventing excessive overpressure and reducing the risk of cracking. Normally, in a fully sealed annulus, once the foam is crushed, additional crushing cycles are unnecessary. However, to protect the steel casing from a possible second pressure increase, different foam compositions can be installed to guarantee additional annular volume.

An issue of control

The collapse volume is specified by the client and is defined as the calculated volume increase of the annulus fluid brought about by thermal expansion between the installation (or ambient) temperature and the operating temperature. The crush percentage is defined as the amount of compression under isostatic load; The foam will yield as a percentage of the syntactic foam volume. This value is usually between 25 and 35 percent, depending on the particular foam formulation. From the collapse value and crush percentage, a total volume of foam required may be calculated. Safety factors are employed during this design stage to ensure target criteria are always reached.

Case study

Trelleborg manufactured and installed CFW in wells located in the North Sea for a major operator. The well had been in service for several years when production was suspended. While the well was not producing, a portion of the crushable foam wrap was recovered and returned for laboratory testing to establish if it had collapsed in service.

Following testing, it was determined the foam still had its entire collapse capacity remaining, meaning no overpressure situation had occurred. This information was fed back to the operator, who confirmed the monitored pressure within the well had not spiked during its service. The operator was also pleased to know that after several years of operation, the foam still had its entire collapse capacity intact, indicating no buoyancy or volume had occurred over time.

Conclusion

Throughout the world, many deepwater wells have been identified as having conditions that could cause a trapped annulus and allow APB to affect well integrity, causing a real risk within the oil and gas industry — something that causes unscheduled downtime because of pipe damage and failures.

When the risk of subsea annular pressure buildup exists, well designers should consider appropriate mitigation in the fundamental well design and look at the entire APB mitigation toolkit to ensure they select the most appropriate mitigation technique for the life of the well. As drilling continues to travel to greater depths in many operating temperatures, this requirement will become even greater.

Andy Smith has more than 10 years of experience working in the offshore subsea industry and has been with Trelleborg for more than 15 years. He understands the subsea installation and production operations with a concentration on riser towers, installation buoyancy, buckling mitigation buoyancy, cable and flowline protection and crushable foam wrap. Smith currently specializes in buoyancy and downhole products, however, he is most familiar with hot and cold cure epoxy resin syntactic systems. Visit trelleborg.com for more information.