The equipment testing phase is an essential one — Without it, operators and engineers cannot be sure their equipment is reliable or accurate. But sometimes physical testing does not provide enough performance data to make design decisions. When this happens, another testing option is using virtual prototyping and fluids simulation.

On June 13, Flow Control and Autodesk will present a webinar on this process and answer your design questions. The free event is geared toward all computational fluid dynamics (CFD) users, including beginners. Autodesk’s Ryan Abel spoke with us about virtual testing to prepare us for the webinar.

What benefits does virtual testing offer, especially for beginners?

- Visualization of key performance

- Small changes can have a big impact

What is one of the biggest misconceptions you find that people have about CFD analysis and virtual testing?

- It is hard to use and can’t solve their problems.

How does using the cloud improve the design and testing process?

Scaling with the design process. Getting answers faster makes the results that much more valuable.

Are there any applications or common challenges for which CFD is particularly useful?

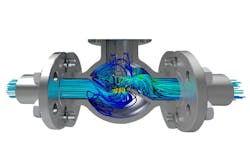

Pumps, valves, fuel distribution systems, HVAC equipment, heat exchangers, power generation equipment

What three key takeaways can attendees expect after participating in this webinar?

- CFD just got easier.

- The cloud is real.

- Autodesk is a simulation company and our technology is strategic to the future of making things.

The most efficient, longest-lasting equipment has benefited from good design. From initial concept to the testing phase, virtual testing help engineers ensure they products they design are built to last.

LIVE EVENT

Virtual Testing: Make Products Work Before Making Them Real Tuesday, June 13, 2017 1 p.m. Central Daylight TimeRyan Abel received a master’s degree in mechanical engineering from Lehigh University. He has more than a decade of firsthand analysis experience in the build environment including training, support and consulting, and he is now part of the Simulation Business Development team focused on CFD.