Although power failures at pumping stations are rare, experts responsible for safety and efficiency at these complex installations take no chances. They spend countless hours and costly resources to prevent any kind of power outage, distortion or noise from disturbing the operation of the equipment and processes at installations throughout the world.

Today’s pumping stations require constant, reliable system-wide control. This is typically accomplished with monitoring, using supervisory control and data acquisition (SCADA) systems and programmable logic controllers (PLCs). Without the continuous measurement and control of pumps and valves, built-up pressures can potentially burst pipes, check valves can remain open, etc., all of which cause cascading damage down the pipeline.

Despite improvements, SCADA and PLCs are extremely sensitive to power anomalies such as brownouts, blackouts, spikes and noise pulses. While electric utilities make every effort to provide relatively stable power, problem-free service is not guaranteed. Therefore, specifying an uninterruptible power supply (UPS) system is like getting an insurance policy against the consequences of unpredictable power.

UPS selection

Oil and gas industry engineers responsible for specifying pumping station design and equipment must consider many factors when deciding which UPS systems are best suited for their applications. One of the first decisions is identifying which type of UPS is needed.

Standby (offline) — The standby UPS is the simplest and least costly design with the least protection provided. The standby UPS is designed to pass the input voltage through to the load. This is not conditioned power, and it is not acceptable for industrial settings with periodic voltage, frequency deviations and transients to pass through to the load. These power anomalies cause dropped loads and data loss.

Line interactive — The line interactive UPS is a step up from the standby UPS. These UPS systems monitor the incoming power and buck or boost the voltage as needed. This UPS is ideal for applications in which the utility is clean. If this UPS system is placed in an industrial setting, electrical line noise, frequency variations and harmonic distortions are passed downstream to the critical loads.

Double conversion — The double conversion UPS provides the highest level of protection. The input isolation transformer prevents electrical line noise, voltage, frequency deviations and harmonic distortions from passing downstream. The alternating current (AC) input voltage is first converted to direct current (DC) and then back to AC. If a power loss occurs, transfer time to the battery is zero, making it ideal for sensitive equipment.

A double conversion UPS also has an internal static bypass switch. This static bypass switch provides a zero-transfer time to the alternate bypass source if batteries are depleted, if UPS maintenance is required or if a catastrophic failure occurs.

Environmental and mean time between failure considerations

Since many pumping stations are in remote and rugged environments, the UPS system should be designed to tolerate wide temperature swings, high humidity, corrosive environments, particulate contamination and high altitudes. Higher-power applications will also have epoxy-coated or nickel-plated copper bus bars, special anticorrosion terminal connections and acid-resistant metal surface coatings.

Industrial UPS equipment should have design margins built into components for the UPS system to have a 20- to 30-year life span when operating in industrial environments. These longer life spans are essential for these critical processes.

The industrial UPS should also have long-term support. When one considers the life cycle costs of a UPS, especially in large process applications, an industrial UPS design with a scheduled critical parts replacement program is a much lower cost solution compared to UPS replacements and pipeline shutdowns.

Network and intelligent communication

The latest UPS technology guards against malfunctions to ensure servers send the proper shutdown sequence prior to and after a power loss. The newest software built into UPS systems monitors remaining battery life more accurately and initiates control server shutdown protocols based on real-time, true battery life information.

Calculating remaining battery time is essential to create dynamic protocols for safe shutdown procedures of system control servers. A battery has a discharge design life based on the battery type, room temperature, age and number of discharges that have occurred.

To help users maintain control of complex remote pumping stations, other features built into UPS systems include:

- Storage of up to 2,000 data events

- Communication of customer-defined alerts pertaining to data log storage (i.e., an alarm alert when a certain percentage of the data log is full [percentage is configurable])

- The ability to retrieve data over Ethernet, including the data log

- Scheduled station battery equalization

- Constant “heartbeat” that monitors all servers and produces status reports

- Control of shutdown time intervals

- The ability to specify static IPs for all servers

- Time syncing the UPS to Network Time Protocol

- Two network adapters for redundancy and signal isolation

- The ability to test and initiate server shutdown from the UPS front panel and web interface

- Retrieval of the data log over TCP/IP using a web interface

Battery charger

The battery charger must be sized large enough to supply the inverter while simultaneously recharging a fully discharged battery bank within the specified amount of time. The output voltage regulation is important since the battery requires a precise charging voltage with minimum ripple voltage for maximum life and minimal maintenance.

Battery chargers should have temperature compensation charging. The charging process is managed by a chemical reaction and is impacted by ambient temperatures. The higher the temperature, the more current the battery accepts, causing more heat to be generated. Eventually the internal heat generated exceeds the rate at which the heat can be dissipated into the environment and a thermal runaway event occurs. To prevent such a situation, temperature compensation and maximum recharge current should be considered.

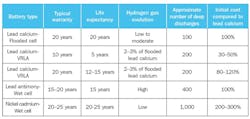

Battery selection

Several criteria can be used to help make the selection process a little easier and ensure the proper battery is employed for a given application. With careful thought and planning, the UPS battery will no longer necessarily be viewed as the weakest link in the power protection chain.

Many things should be considered when specifying a UPS for industrial applications. Though industrial UPS systems generally have higher initial costs, they are also more reliable and more serviceable for the life of the plant. Spending a little more on the front end can save a substantial amount of money in the long run.

Mission-critical systems require reliable, clean electricity to drive long-term success and are essential to the fail-safe equation. Selecting the right UPS is the first step toward ensuring the UPS system’s smooth and continuous operation. With the many crucial design factors to consider, the decision can be daunting. Consider the factors presented earlier to determine and design your insurance policy — the UPS system.

Resources

- NEMA Standard PE 1-2012 – UPS Specification and Performance Verification

- NEMA Standard PE 5 1997 – Utility-Type Battery Chargers

- IEEE-519 Recommended Practices and Requirements in Electrical Power Systems

- IEEE-946 Recommended Practice for the Design of DC Auxiliary Power Systems for Generating Stations

- IEEE-1184 Guide for Batteries for UPS Systems

- IEEE-485 Recommended Practice for Sizing Lead-Acid Batteries for Stationary Applications

- IEEE-1115 Recommended Practice for Sizing Nickel-Cadmium Batteries for Stationary Applications

- IEEE-693 Recommended Practice for Seismic Design of Substations

As an applications engineer at AMETEK Solidstate Controls, David McKinnon provides presales technical quotations and in-depth technical requirement analyses for customers to help them determine their specific power needs. Learn more at solidstatecontrolsinc.com.