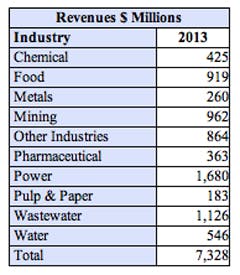

The report shows the power industry will be the largest purchaser of sedimentation and centrifugation equipment. Power plants extract 10 times more water than do municipalities. Before it can be used as boiler feedwater or even for cooling, the water must be purified. Clarifiers are used for primary particle removal. The flue gas desulfurization systems utilize hydrocyclones, centrifuges and clarifiers. Geothermal plants are also purchasers. Biomass energy plants require this equipment for the incoming water and for the scrubber wastewater clarification.

Municipal wastewater treatment plants will be the second largest group of purchasers. Decanter centrifuges are used to dewater the sludge. A series of clarifiers is needed in the physical and biological treatment of the sewage.

The mining industry will be the third largest purchasing group, according to the report. The mining industry is expanding capacity at greater than average rates. It is also retiring and replacing capacity. Clarifiers, thickeners and hydrocyclones are used in the beneficiation processes as well as treatment of tailing.

The food industry will also be a major purchaser. Centrifuges are often used to make products. Disc centrifuges are used to purify wine and juices. The dairy industry is also heavily reliant on centrifuges.

The pharmaceutical and biotechnology industries utilize disc centrifuges to purify products as well. These devices are often the largest capital expense in the process.

For more information on the Sedimentation/Centrifugation World Markets report, click here.