The two most common valves types are linear (go up and down), such as gate and globe valves, and rotary (quarter turn), such as a ball or butterfly valves. The quarter-turn valves usually move between the open and closed position by moving the stem 90 degrees. The majority of valves that are pneumatically actuated are rotary valves.

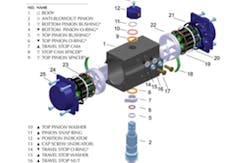

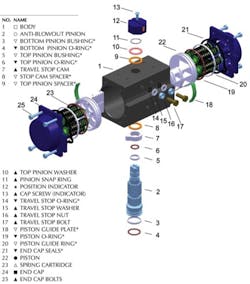

The primary principle behind quarter-turn actuation is a rack and pinion. This is where a shaft with teeth interfaces with a pinion that also has teeth (like gears). When the rack moves, the piston moves in a 90-degree rotation, which is attached to a valve stem, such as a ball or butterfly valve. This mechanical linkage between the rack and pinion is what actuates the valve (moves the valve open or closed).

Sometimes there are springs on the opposite side of the shaft, which will push the valve back to its original position. In the case of lack of pressure inside of the actuator, the springs will return the rack back to its original position. These Spring-Return Pneumatic Actuators are very common when the valve needs to fail in a certain position. The most popular configuration for these types of valves and actuator packages is “Air to Open (ATO), Valve Fails Closed” on loss of air pressure.

The other type of actuator is a Double-Acting Actuator. This type of actuator needs to have air pressure on both sides of the piston to push it back and forth. This air pressure in turn opens or closes the valve. Double Acting Actuators are often referred to as “air-to-open, air-to-close.” These valve and actuator packages will “fail in place” with loss of air pressure.

A popular accessory to be added to these actuated valve packages is a limit switch. Limit switches give a conformation electrical signal back to a PLC or DCS that a valve is in fact open or closed.

Gilbert Welsford Jr. is managing director of valve supplier ValveMan (www.valveman.com). He can be reached at [email protected]. Editor’s Note: This blog post originally appeared on ValveMan.com and has been adapted with permission.