Crude oil volatility decreases since peaking in March

Graphics courtesy of the U.S. Energy Information Administration

High uncertainty regarding supply, demand and inventories led to highly volatile crude oil prices during the first three months of 2016, according to the U.S. Energy Information Administration (EIA).

Crude oil prices have now risen since peaking in March, while economic growth concerns have lessened and inventory growth has slowed down since the beginning of 2016.

The 30-day oil price volatility measure rose to 45 percent on March 4 and fell to 33 percent on April 18. The March levels were the highest since early 2009. The 2015 volatility average was 27 percent.

The EIA notes some reasons for volatility include uncertainty about:

- Future production levels in key oil-producing nations

- Global economic growth, particularly in China and other emerging market economies

- Growth in U.S. gasoline demand following higher consumption levels in 2015

- Crude oil inventories and storage capacity constraints

Most US gasoline is now 10 percent ethanol

Blends of petroleum-based gasoline with 10 percent ethanol, known as E10, account for more than 95 percent of the fuel consumed in motor vehicles with gasoline engines in the U.S., the EIA said.

The total volume of ethanol blended into motor fuels has increased since 2010, albeit at a declining rate of growth, the EIA said. Meanwhile, the use of ethanol-free gasoline (E0) by fuel consumers has declined.

The federal renewable fuel standard (RFS) requires that renewable fuels, such as ethanol, be blended with transportation fuels in an effort to reduce emissions.

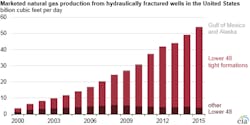

The EIA reported that hydraulic fracturing is responsible for about two-thirds of marketed gas production in the U.S., greater than the amount of crude oil produced by the same method.

Using data from IHS Global Insight and DrillingInfo Inc., the EIA’s profile shows a production increase with hydraulic fracturing. Less than 7 percent of the national marketed gas total was produced by about 26,000 hydraulic fracturing wells in 2000. Approximately 300,000 wells produced about 67 percent by 2015.

The EIA measures natural gas production in three ways:

- Gross withdrawals — Full volume of compounds extracted at the wellhead

- Marketed natural gas — Excludes natural gas used for repressuring the weel, vented and flared gas, and nonhydrocarbon gases.

- Dry natural gas — Also known as consumer-grade gas, this process extracts hydrocarbon gas liquids and removes impurities like water vapor and noncombustible gases.

Strong demand predicted to boost gas handling equipment market

In a new report, Research and Markets said it expects the industrial gas handling equipment market to be worth $72.22 billion by 2021, after growing at a compound annual rate of 6.82% from $51.93 billion in 2016. The demand will be driven by increasing demand for industrial gases for diverse applications in the chemical, metal fabrication, health care & medical and oil & gas sectors.

According to the report, the gas delivery systems segment — including gas cylinders, control panels, manifolds, switchovers, high pressure changeover systems and protocol stations — saw the largest demand in 2015 and is expected to hold the leading position through the forecast period. However, the fastest growth will be seen in the cryogenic products segment.

Atmospheric gases accounted for the largest consumption of industrial gas handling equipment in 2015 because of the huge demand for these gases in industrial applications. Demand is also growing rapidly for hydrogen and acetylene gas in the chemical, food processing and metallurgical industries.

Looking ahead, product innovations and technological developments are expected to create strong investment opportunities in the industrial gas handling equipment market. Strict government standards and regulatory legislation will also have a positive impact by requiring the safe and proper use of industrial gas handling equipment.