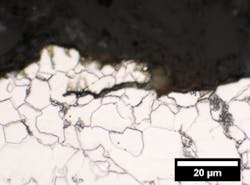

Image courtesy of Sowards/NIST

U.S. production of ethanol for fuel has been rising quickly, topping 13 bill. gallons in 2010. With the usual rail, truck and barge transport methods under potential strain, existing gas pipelines might be an efficient alternative for moving this renewable fuel around the country. But researchers at the National Institute of Standards and Technology (NIST) caution that ethanol, and especially the bacteria sometimes found in it, can dramatically degrade pipelines.

At a conference this week,* NIST researchers presented new experimental evidence that bacteria that feed on ethanol and produce acid boosted fatigue crack growth rates by at least 25 times the levels occurring in air alone.

The NIST team used a new biofuels test facility to evaluate fatigue-related cracking in two common pipeline steels immersed in ethanol mixtures, including simulated fuel-grade ethanol and an ethanol-water solution containing common bacteria, Acetobacter aceti. Ethanol and bacteria are known to cause corrosion, but this is the first study of their effects on fatigue cracking of pipeline steels.

Ethanol, an alcohol that can be made from corn, is widely used as a gasoline additive due to its oxygen content and octane rating. Ethanol also can be used as fuel by itself in modified engines. The NIST tests focused on fuel-grade ethanol.

The tests were performed on X52 and X70 pipeline steels, which are alloys of more than a dozen metals. Simulated fuel-grade ethanol significantly increased crack growth at stress intensity levels found in typical pipeline operating conditions, but not at low stress levels. The cracking is related to corrosion. The X70 steel, which is finer-grained than X52, had lower rates of crack growth at all stress levels. This was expected because larger grain size generally reduces resistance to fatigue. In the bacteria-laden solutions, acid promoted crack growth at stress intensity levels found in typical pipeline operating conditions.

Preliminary tests also suggested that glutaraldehyde, a biocide used in oil and gas operations, may help control bacterial growth during ethanol transport.

To read the full NIST report on this story, click here.

* J.W. Sowards, T.D. Weeks, J.D. McColskey, C. Williamson, L. Jain and J.R. Fekete. Effect of ethanol fuel and microbiologically influenced corrosion on the fatigue crack growth behavior of pipeline steels. Presented at DOD Corrosion Conference 2011, La Quinta, Calif., August 1, 2011.