Flow sensors are used to monitor and measure the flow of liquids, gases, steam/vapor and slurry in pipes. These sensors are attached to the inside or outside of a pipe and used to measure the material flow volume, mass or speed. To measure flow accurately, flow sensors consider factors such as differential pressure, process temperature, viscosity and absolute pressure. Flowmeters and flow sensors provide an electronic output signal, which is proportional to the flow inside the pipe; the only difference is that flowmeters have an integrated display to indicate the flow rate.

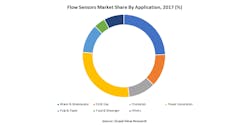

Since the commercial introduction of flow sensors in the global market, they have become one of the essential tools across various industry verticals, including oil and gas, waste and wastewater, chemical and petrochemicals, food and beverage and power generation. Over time, the market has undergone prominent evolution and developments; for instance, modern flow sensors possess features such as digital readouts, advanced sensors, and wireless control using Internet of Things (IoT).

Current global scenario and footprints of flow sensors worldwide

According to a recent study by Grand View Research, the flow sensors market is expected to grow at a CAGR of 6.03 percent from 2018 to 2025. The market was valued at $6.94 billion in 2017. The growing demand for flow rate measurement in water and wastewater management applications worldwide is expected to drive the growth of the global flow sensors market in the coming years. The adoption of flow rate measurement technologies has gained significant traction in the oil and gas, pulp and paper, food and beverage and power generation sectors worldwide and is projected to further increase over the next seven years. However, their demand would be particularly noteworthy in the oil and gas and chemical and petroleum refinery sectors owing to the recent detection of shale gas reserves in the North American, European and Asia Pacific regions.

The incumbents of flow sensors market are observed focusing on the oil and gas sector and investing extensively in developing innovative products and solutions that measure the flow rate of liquids, gases and vapors. The demand for intelligent flow sensors is expected to increase over the forecast period owing to the integration of IoT, which has led to the introduction of smart flow rate measurement solutions.

The Asia Pacific region is poised to emerge as the fastest-growing region over the forecast period, mainly due to the rapid urbanization triggering the need for adequate power generation and water and wastewater management. However, the lack of understanding pertaining to operational processes of smart flowmeters among unskilled labor, along with the high initial costs associated with these advanced products, are some factors that can hamper the growth of the market. Similarly, MEA region’s political instability and lack of adequate calibration facilities are also likely to hamper the market growth in the region.

Courtesy of Grand View Research

Custody transfer

The term custody transfer is referred to as the transactions involving the transfer of physical substances (oil, gas or petroleum) from one operator to another. In fluid measurement, custody transfer is a point of sale where the fluid is measured and sold by one party to another. During the custody transfer, precision and accuracy in the measurement of the material are of utmost importance.

Flow sensors are used for measurements due to their high level of accuracy. They must be approved by global and government organizations such as the American Petroleum Institute (API). The custody transfer operation can take place at various points along the way; for instance, gas or oil can be transferred from a production facility to a truck, barge, ship, railcar and finally to a refinery.

In an attempt to avoid errors in measurements, custody transfer involves:

- Industry standards regulating the transferring of petroleum products

- Agreements between the organizations/authorities involved in the custody transfer

- Stringent government regulations and taxation

The impact of the oil and gas sector on the flow sensors market

It is difficult to analyze the flow sensors market accurately without taking into consideration the effects of lower oil prices. The drop-in oil prices have resulted in delay or cancellation in many oil and gas projects, which have indirectly hampered the growth of the flow sensors market. The lower oil prices can be attributed to the growing potential threat posed by the U.S. shale gas production.

The Organization of Petroleum Exporting Countries (OPEC) was established in September 1960. Founding members of OPEC were Kuwait, Iraq, Iran, Saudi Arabia and Venezuela. Later, countries such as Algeria, United Arab Emirates, Libya, Equatorial Guinea, Congo and Nigeria joined in. The objective of the organization is to unify and coordinate petroleum policies among its members to secure stable and fair prices for petroleum producers, provide regular supply to consumer nations and offer fair and appropriate returns on capital to the investors in the industry.

The prices of oil recovered and gained stability between 2016 and 2017. New flow sensor technologies such as Coriolis flow sensors and wireless magnetic flow sensors have facilitated the market in recovering from its downfall, thereby achieving moderate growth in the last two years. Other prominent industries such as water and wastewater, chemicals and food and beverages were not affected by the low oil prices. The growth of these industries helped the flow sensors market to make up for the losses ensued due to the decline in growth of the oil and gas industry.

Key trends shaping the industry

- Factors such as reliability, accuracy, cost effectiveness and the need for less maintenance are ideally considered while opting for flow sensors; cost effectiveness is the most prominent parameter.

- Water and wastewater management is likely to emerge as a significant application sector over the foreseeable period.

- The emergence and discovery of shale gas reserves across the globe are expected to generate lucrative opportunities for the oil and gas industry and flow rate measurement solution providers such as manufacturers and service providers, especially in the North American region.

- Businesses in the Middle Eastern countries such as Iran, Iraq and Syria are highly influenced by the political instability, whereas countries such as the UAE, Saudi Arabia, Oman and Qatar are focusing on developing their markets by following friendly relations with the Western countries and their eminent manufacturers.

- Custody transfer application in the oil and gas sector is one of the critical sub-applications creating lucrative opportunities for the ultrasonic and Coriolis flow sensors, leading to the integration of IoT and the adoption of smart flow sensors.

- Coriolis flow sensors are predicted to emerge as the most demanding product type due to their enhanced smart capabilities to measure liquid carbons and the flow rate reliably and accurately in the trending custody transfer application.

- The Asia Pacific region is subject to portray the highest growth rate over the forecast period owing to the substantial demand and adoption arising from its developing nations such as China, India and other South East Asian countries.

- Calibration of flow sensors poses to be a challenging factor as it is a time-consuming process. Its effects are observed particularly in the Middle Eastern and African market as there are fewer calibration facilities located in the region.

Vikrant Patil is a research analyst with Grand View Research and is responsible for the company’s syndicate and consulting market research across the information, communication and next-generation technologies domains.

Ajinkya Ponkshe is a lead analyst and consultant with more than 5 years of experience in the consumer electronics, next-generation technologies and ICT domain. He has worked on more than 50 assignments and consult projects at Grand View Research in the field of next-generation technology across the value chain.