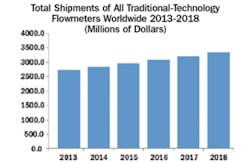

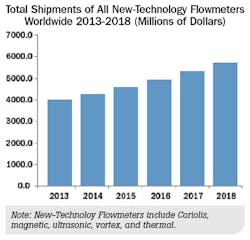

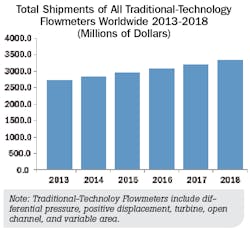

The global market for "new-technology" flowmeters will exceed $5.7 billion in 2018, with "traditional-technology" flowmeters eclipsing $3.3 billion in the same year, according to a new study by Flow Research Inc. These findings come from Flow Research’s Volume X: The World Market for Flowmeters, 5th Edition, which examines the flowmeter market as a whole, covering leading technology categories such as Coriolis, differential pressure, magnetic, positive displacement, thermal, turbine, ultrasonic, vortex, and variable area.

New-Technology Flowmeters

Flow Research defines "new-technology" flowmeters as meter types introduced on the open market after 1950. In this category, Flow Research says the Coriolis and ultrasonic flowmeter markets are showing the fastest growth, while the vortex, magnetic, and thermal flowmeter markets are growing more slowly, but still showing significant upticks.

Flow Research projects a compound annual growth rate (CAGR) in revenues for the total worldwide ultrasonic flowmeter market of 9.0 percent through 2018. The projected CAGR for the new-technology flowmeter market is 7.5 percent from 2013 to 2018. The most rapid growth is expected in China, the Middle East, and in developing Asian countries.

The search for energy sources is a major driver of the worldwide flowmeter market, with flowmeter growth strongest in the oil & gas industry, according to Flow Research. With crude oil selling in the $100-per-barrel range, measurement accuracy and reliability are becoming increasingly important. Flow Research says ultrasonic and Coriolis flowmeters for custody-transfer measurement are benefiting from this need. Suppliers of ultrasonic flowmeters have brought out new multipath ultrasonic meters with enhanced features for custody transfer of natural gas and petroleum liquids. And four Coriolis suppliers have introduced new Coriolis flowmeters designed for pipes with 8"-16" diameters. These new Coriolis meters target measurement of natural gas and petroleum liquids and are mainly designed for custody-transfer applications.

Traditional-Technology Flowmeters

Flow Research defines "traditional-technology" flowmeters as meter types introduced on the open market before 1950. In this category, Flow Research says differential-pressure (DP) and open-channel flowmeter markets are showing the fastest growth, with the DP flowmeter market the largest of the group in terms of revenues. Flow Research projects a compound annual growth rate (CAGR) in revenues for the total worldwide traditional-technology flowmeter market of 4.1 percent from 2013 to 2018.

Despite a trend toward new-technology flowmeters, Flow Research says traditional-technology flowmeters have been holding their own in the worldwide flowmeter market. One reason is their large installed base. Differential-pressure flowmeters have been around for over 100 years, and have been extensively studied and used for liquid, gas, and steam flow measurement. Differential-pressure and turbine flowmeters in particular were the first to receive approvals from the American Gas Association (AGA, www.aga.org) for use in custody transfer of natural gas. While Coriolis and ultrasonic flowmeters have also received corresponding approvals in the past 20 years, DP and turbine meters were already entrenched in the custody-transfer market at this point.

Positive-displacement flowmeters have also received approvals from the American Petroleum Institute (API) for use in custody-transfer measurement of petroleum liquids. Meanwhile, turbine flowmeter suppliers have been very active in developing products with new features, such as ceramic and sapphire ball bearings for improved longevity.

Another important area of development is primary elements, which are used together with differential-pressure transmitters to measure flow by placing a constriction in the flowstream. Flow Research says suppliers are innovating in the area of primary elements to enable efficiencies in the area of calibration and straight-run piping requirements.

For more details on Flow Research’s Volume X study, visit www.flowvolumex.com.