The first floating liquefied natural gas platforms (FLNGs) are set to become available during 2017, which will harness vast quantities of previously untapped sources of energy. The location of many of these fields makes the issue of gas transportation highly challenging. The liquefaction process, which reduces the volume of space taken up by the gas on transport vessels, is crucial. This places greater demands on cooling techniques and the equipment that supports this process. At the same time, the need for floating production storage and offloading (FPSO) vessels to access cold water is highlighted as the availability of colder water is known to significantly improve topside efficiency, while also reducing operational expenditure across the whole system. This article examines the issues around liquefaction and seawater intake, the new technologies being developed to meet these unique demands and how this equipment has been tested to meet the most stringent of international standards.

The advent of FLNGs

Developments in the oil and gas sector continue to grow — especially in the area of extraction. The demand for alternative sources of energy that are more sustainable and environmentally friendly continues to accelerate the rate of extraction of natural gas, which presents a number of advantages over oil.

One of the issues around gas is its location — frequently in remote offshore fields — and the associated challenge of transporting it from the point of extraction. The remoteness of many of these fields — under the sea bed, hundreds if not thousands of miles from land — will, in most instances, make the use of pipelines an economic and logistical impossibility. The alternative is the use of specialist transport vessels or tankers. The goal here, especially given the considerable distances involved, is to transport it cost-effectively, which means containing as much natural gas as possible on a single vessel.

The flexible design of the submarine flexible water intake hose and continuous inner liner with integrated gasket provide a solution for seawater extraction.

The importance of cooling and cold water

To cool cold water, the natural gas needs to be converted into liquefied natural gas (LNG), a process that requires cooling through the use of heat exchangers. While air can be used for this, it is not especially efficient. The more effective cooling medium that can be used is seawater, which is abundantly available around FLNGs and free of charge. The efficiency and speed of the liquefaction process (and therefore the effective filling of the storage tanks on the vessel and the speed at which it can leave the FLNG and return to shore) are governed to a large extent by the temperature of the water used for the cooling. The colder the water, the more rapidly the natural gas will condense into LNG. When it is noted that 600 cubic meters (m3)/21,189 cubic feet (ft3) of gas will condense into 1 m3/35 ft3 of LNG, the importance of this process becomes abundantly clear. Reliability is key and downtime can cost thousands of dollars each minute, so it is vital that any equipment used is robust, dependable and requires minimal maintenance.

The use of seawater for cooling is well-established in the oil sector, with water intake lines being a common sight on FPSOs. The operation of FPSOs is less demanding on water intake, and intake lines on FPSOs typically only extract water from a maximum depth of around 80 meters/262 feet. Things are changing since colder water is key to significantly improving the topside efficiency of new projects. Retrofitting existing installations with deeper suction is also under examination. Depending on the installation, a deeper suction point can be easily implemented with minimal modifications of the main structure.

On FPSOs and FLNGs, the usual configuration involves the use of free-hanging risers connected to the underside of the hull. The risers can be bundled or in stand-alone configuration. Water is collected using sections of hose, with the bottom of the riser fitted with a strainer for initial filtration. An inlet is present for the injection of hypochlorites, which controls the development of marine growths such as algae — these protect the inside of the riser, rather than the strainer itself.

The average water temperature drops rapidly with depth. For example, at 160 meters/525 feet below surface level, water temperature is typically 10ºC/18ºF cooler than at the surface. Extracting water from as great a depth as possible to optimize the efficiency of the cooling process has clear value. Maximizing the flow rate of the cooling water also aids in accelerating liquefaction, but creates further physical challenges for the equipment used for this purpose. Typically, a flow rate of 30,000 to 50,000 cubic meters per hour 1.05 million to 1.77 million cubic feet per hour is needed, while the suction lines will require a large bore of between 24 and 40 inches/600mm and 1 meter to ensure any pressure drops are limited. In suction applications where differential pressure is negative, the theoretical maximum permissible pressure drop is 1 Bar. However, in practice, any drop in pressure needs to be limited to around 0.1 to 0.5 Bar according to Net Positive Suction Head and the arrangement of the suction pumps.

Physical demands on extraction systems

The key issue concerning seawater intake hose design is length. Given the established desire to extract cold seawater, the requirement is for hoses with a length of 150 to 600 meters or longer to access deeper and colder water. The greater depth at which these hoses are now located means they are more subject to the effect of current which induces lateral motion. This has to be carefully managed to avoid the risk of physical clashes with other equipment present, such as adjacent production risers or mooring lines. For this reason, a heavy weight of up to 100 or even 150 tonnes can be attached to the bottom of each riser to ensure it remains stationary even in strong currents. However, this places additional physical strain on the hose.

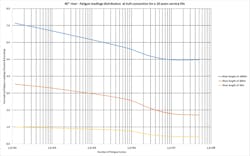

Fatigue loading cycles comparing various riser lengths

This is not the only force acting on the hose that might compromise its integrity if it is not sufficiently robust and well-designed. The connection of the riser to the hull is subject to a variety of significant mechanical loads: a vertical force resulting from the weight of the riser and vessel motions; a horizontal force created by drag on the riser; and the normal rotation of the vessel hull in the form of pitching, yawing and rolling. Tensile loads of between 50 and 300 tonnes typically depend on the system’s configuration. Coupled to this is a bending moment at the top of the riser, typically in the range of 200 to 1,200 Kilonewton meters. These forces place significant physical demands on the hose itself and the connection mechanisms chosen, making materials selection and system design and configuration pivotal.

The effect of the hypochlorites on the hose material must also be taken into account — some grades of rubber, for example, are prone to swelling and performance loss in relation to fatigue and static loads. Strong thermal insulation properties are desirable to keep the water cool on its journey to the surface.

Materials choice

When it comes to seawater intake hoses to meet these unique and varied lists of criteria, specifiers have a number of options to select from in terms of materials.

One option is high-density polyethylene (HDPE), which offers initial purchase cost efficiencies compared with some alternatives. However, as a plastic product, issues can include tensile strength and creep under heavy loading. Plastic pipes float and are subject to movement as a result of current. In addition, the use of weights to hold these pipes in place can cause stress in the material and lead to premature failure, and the manufacture of HDPE pipe creates a welded flange which is in itself a potential source of weakness.

Another option is steel, which is stronger but more expensive, heavy and does not typically perform well in the area of thermal insulation. Steel has the advantage of being naturally heavy, which stabilizes the riser. However, corrosion is an issue and fatigue performance of weld filets can also be challenging to demonstrate.

A third option and one already well-established in similar applications in the oil sector — especially in FPSOs — is a submarine flexible water intake hose system based on a bonded hose with a continuous inner liner and outer cover. The hose comprises steel cables bonded in a rubber matrix and is designed to optimize thermal insulation, which combine bending and tensile strength of up to 1,000 tonnes (compared with typically 30 to 60 tonnes for HDPE) in a strong yet flexible unit thanks to an integrated bending stiffener. Since these hoses can be supplied in lengths of up to 1,000 meters, significantly greater depths are achievable through a system with no weak points. The hoses can also come as part of a complete turnkey system, including a strainer and hull interface components for sea chest and caisson configurations.

The design criteria for this system have been defined to deliver ultra-low pressure drops and to optimize flow rates. Special coatings are also applied to the product to protect the strainer from corrosion, marine growth and erosion caused by water entering the system. In an effort to reduce cost, some manufacturers have suggested a configuration based on bonded sections at the top and bottom of a 1,000-meter length of HDPE. However, any joining of hoses introduces additional possible points of failure and might not be a risk worth taking.

Stand-alone or bundled risers?

Whatever hose material is specified, system designers can choose from either a stand-alone or a bundled riser configuration depending on individual application requirements and preference.

In a stand-alone riser configuration, each riser is physically separate from the others, typically between 5 and 20 meters. This is the most common configuration because it makes for easy installation, simpler design and fatigue assessment. The multiple nature of this solution means more space on deck and piping are required. Risk that individual risers can clash as a result of the effects of current is greater.

Bundled risers typically comprise a group of up to nine risers gathered together. While this removes the risk of clashes, has a smaller footprint and demands less space on deck, these systems can be much more challenging to design and install. It is more difficult to locate and remedy a problem in the riser bundle; even small maintenance jobs usually require complete system shutdown for them to be undertaken.

Submarine flexible water intake hose systems are equally suitable for stand-alone and bundled configurations, perhaps even more so for bundled configurations since they are highly unlikely to require any repair during service.

System installation can take place vertically from the FLNG deck for easy flange alignment. Installation can also take place with assembly beside the hull with connection of the intake flange by divers in the riser caisson in conjunction with lowering of the hang-off riser head. The system is designed for hydraulic simultaneous flange tightening, ensuring reliable and homogeneous bolt preloading and therefore more reliable and consistent long-term performance.

Verification of performance qualities

For a pipe to be regarded within the industry as entirely suitable for FLNG applications in demanding conditions, it must be certified to the stringent international American Petroleum Institute (API) Spec 17K Standard. Specification for bonded flexible pipe is a must. The testing process typically measures factors such as response to stress and strain, then computes fatigue for the whole service life, ensuring a minimum safety factor of 10.

During internal tests undertaken on the submarine flexible water intake hose — all under third-party observation — the hose was subjected to uniaxial and multiaxial loads to validate predictions made from finite element analysis, as well as testing under extreme load conditions to verify its performance against tensile, bending and combined loads.

The fatigue test based on the anticipated hydrodynamic outputs in a real 20-year project application resulted in mean damage of 0.00997. This result was based on a 300-meter riser subject to typical Malaysian metocean data. With a safety factor of 10, this meant the mean fatigue damage corresponds to 200 years of fatigue. A dedicated load case was simulated to reach mean damage of 1, with a survival load case simulated in front of independent third-party witnesses. Bolting process verification ensured accurate fatigue management. In all tests the hose products comfortably exceeded the required performance levels. This was demonstrated when the hoses showed no ill effects even under survival case loadings.

The next phase

The unique design of the system, drawing on design and technology proven in the oil sector, created a seawater intake system that meets the requirements of FLNG and FPSO designers seeking a reliable means to extract cold seawater. It is the first system of its kind to achieve API 17K certification.

The system has been specified for the Shell Prelude project in the Timor Sea, the first major FLNG platform that will go live globally.

Jonathan Petit is a product manager for Trelleborg Oil & Marine in charge of SWILINE hose. Petit is an expert in crude oil offloading solutions, seawater intake risers, rubber material, chemical transfer solutions, LPG transfer solutions and offshore/onshore installation. He has a degree in mechanical engineering.

Trelleborg provides engineered polymer solutions that seal, damp and protect critical applications in demanding environments. The Trelleborg Group has annual sales of $3.60 billion in more than 40 countries. The Group comprises five business areas: Trelleborg Coated Systems, Trelleborg Industrial Solutions, Trelleborg Offshore & Construction, Trelleborg Sealing Solutions and Trelleborg Wheel Systems. For more information, visit trelleborg.com.