A manufacturer of tortilla products utilizes large supplies of cooking oil as part of its production process of frying corn and flour tortilla chips. Two separate 20-foot tanks located inside the processing facility hold supplies of virgin and wasted cooking oil. Managing oil levels in these tanks is important to ensure when to order new supplies of cooking oil and dispose of the wasted stock.

Products supplied

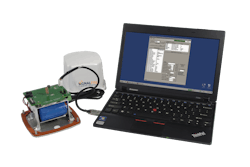

- SignalFire Remote Sensing System (Gateway Stick with Ethernet interface)

- Pressure Scout

- SignalFire Software Toolkit

Challenge

In the past, operators used sight gauges to estimate the tank volumes. Manual estimating is not an accurate science and requires frequent follow up to stay current on tank levels. The customer wanted a method to automate the ordering and removal of their oil consumables.

Solution

A SignalFire Remote Sensing System (SFRSS) configured with a Pressure Scout offered a wireless solution that automated the tank level monitoring process. In addition to eliminating the need for repeated manual measurements of cooking oil, the SFRSS automatically generates an email to the appropriate vendor to reorder a standard delivery volume of virgin oil or to remove a fixed amount of used oil.

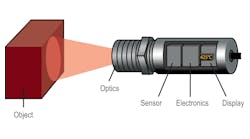

A SignalFire Pressure Scout installed on each tank communicates the relative oil levels by associated tank pressures. By integrating a wireless node, pressure sensor and intrinsically safe internal battery into one package, the Pressure Scout serves as a low-cost alternative to conduit, wired and other pressure sensor solutions.

Pressure data is wirelessly transmitted to a SignalFire Ethernet Gateway that interfaces to an RTA Automation Gateway. The RTA converter analyzes pressure data and sends an email to the cooking oil vendor to take appropriate action when detecting a programmed threshold. Using the SignalFire Software Toolkit, plant managers can check tank levels from the convenience of their personal computers whenever they choose.

Sandro Esposito serves as vice president of sales and marketing for SignalFire Telemetry Inc., with responsibilities for managing the portfolio and commercialization of the company’s wireless telemetry solutions. In addition to having more than 24 years of experience in the process control and automation industry, he holds six patents and has published 12 papers related to industrial controls and smart technologies. A graduate of College Ahuntsic in Montreal, he holds a bachelor's degree in electrical and instrumentation engineering and is actively involved in the International Society of Automation.