Pump Guy,

I am the principal engineer at an energy company in upstate New York. We perform energy audits. We have an upcoming audit on some pumps. I have some questions because I have never worked in maintenance.

What are pump wear rings? I heard that you can improve the performance of a pump by coating the internals with epoxy. Have you mentioned this in your articles? Is there something I can read on this topic?

Ronald A., PE

Hello Ronald,

I’m glad to know someone in the energy sector is thinking about pumps and the energy to operate a pump. I’ll offer some thoughts on wear rings, coatings, and conserving energy.

Wear rings are also called wear bands. Neither of these terms describes the function and purpose of these rings. The rings are not designed to wear, although it happens. A better word is "Efficiency Rings" or "Efficiency Bands."

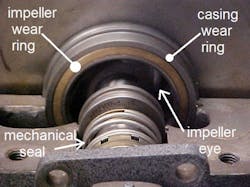

Wear rings are concentric metallic (or other material) rings used on some pumps with enclosed impellers to control and maintain the pump’s original efficiency. The inner wear ring normally seats onto the outside diameter of the eye of an enclosed impeller. This ring locks into place and rotates with the impeller. Dualsuction impellers have two wear rings. The outer ring is normally static and seats into a bore in the pump casing.There is a gap or clearance between the outside diameter of the inner ring and the bore (ID) of the outer ring. The clearance is typically 0.006" to maybe 0.030". The clearance is a function of pump size, design, purpose, and the nature (temperature, lubricity) of the liquid, and any entrained solids (crystals, sediment, contaminants) in the liquid. The rings actually separate zones of high pressure in the pump (discharge pressure) from zones of low pressure in the pump (suction pressure).

This clearance and the recirculation of liquid through the gap becomes part of the pump’s total efficiency. The total efficiency is composed of the mechanical efficiency, the volumetric efficiency and the hydraulic efficiency.

Over time, there is wear or erosion at the strict clearance. A small portion of the pumped liquid recirculates through the wear rings as high pressure searches for low pressure (Pascal’s Law). The erosion is accelerated if the liquid carries crystals or sediment. The gap is destroyed if there is misalignment or shaft deflection leading to rubbing and scraping between the rings.

Ronald, because you do energy audits and you hope people will take your recommendations to heart, let me say that replaceable wear rings are a desirable option to consider when purchasing a new pump.

Cheap pumps (the pumps that normally win a competitive bid) don’t normally carry replaceable wear rings. As the clearance erodes on a cheap pump, it is necessary to install a new impeller and casing to repair the pump. Thus, the cheap pump becomes more expensive to own and maintain than a well-built pump.

I have written about epoxy coatings in previous articles. Epoxy coatings are good where rogue solids (sediment, crystals, fineslurry) can accelerate damage and erosion to the pump internals. The epoxy provides a harder surface to the pump internals. The coating should be reapplied periodically because the coating also erodes.

I think it is a stretch to say the epoxy coatings will improve the efficiency and performance (head and flow) of a water pump. Instead, I’ll say the epoxy coatings can recover some of the pump’s lost efficiency and lost performance from erosion. The epoxy coatings can extend the service life of a water pump with periodical re-coatings.

You ask about wear rings and epoxy coatings because of your energy audit. We should all be concerned with energy and energy savings.

An eroded gap in the wear rings can cause the pump to lose maybe 2 percent efficiency. Replacing the wear rings can recover those lost efficiency points. Epoxy coatings can recover some of the pump’s lost efficiency from erosion and scale.

This is peanuts and not worth 30 minutes of banter in a Friday morning Reliability Meeting. Pipe system design and pump operation influence efficiency and performance much more than epoxy coatings, or an eroded gap on a set of wear rings. I’ll offer a verbal illustration.

Let’s say you need a pump to deliver a liquid at 600 GPM. Your pipe arrangement, elbows, valves, fittings and process devices will eat 90 ft of energy. Flow can oscillate plus or minus 10 percent. You need a pump that develops 600 GPM at 90 ft of head. The best pump for this service might be 80 percent efficient at these duty coordinates.

If the system is designed with this operation window, the pump would always be between 78 percent and 80 percent efficient, or within two points of best efficiency. This is everything you might have gained or lost with those replaceable wear bands or the labor-intensive epoxy coatings, and you don’t have to rebuild the pump to accomplish it. That’s why I use the word "peanuts."

If the pump operators aren’t trained to monitor instrumentation, or if the operators have no gauges to consult, or if the operators don’t know how to correct the pump as the system changes, the system can drag this pump away from these duty coordinates. Here are three classic examples to illustrate how this might happen in a process plant.

Elevated system resistance (a clogged downstream strainer, for instance with no instrumentation to report it) could drag and hold this pump to 200 GPM for hours where the pump may be only 35 percent efficient. Compare 35 percent efficiency to 80 percent efficiency. Over half of the pump’s efficiency is out the window. How does this compare to the 2 percent efficiency loss with eroded wear rings?

Low system resistance (for example, inadequate pressure in a downstream header, with no transducer to report it in the control room) might drag the pump to the right end of the performance curve, where the efficiency might be only 40 percent. How do you feel now about your efficiency gains with epoxy coating?

Maybe a process engineer needs more temperature in a pressurized downstream reactor vessel fed by a process pump. The back-pressure on the pump will rise with the increased temperature. The pump deadheads against the system and flow stalls at 0 GPM and 0 percent efficiency. (The motor is on, but no work or production is performed at 0 GPM. Efficiency is 0 percent.)

There is no flowmeter to report the problem because flowmeters are expensive. So, the operator assumes he is pumping into the reactor vessel because the motor is on and the valves are open.

Before long, this pump will go to the shop with premature seal or bearing failure. And while in the shop, the engineer tells the mechanic to replace the eroded wear bands to recover 2 percent efficiency. Am I making sense?

I know there are pump operators who don’t pay attention to their instrumentation (gauges, flowmeters, level indicators). And there are many more pump operators with no gauges to interpret. They do the best they can with the cards they were dealt by the production engineer.

As I write these words, there are a few pump operators in every process plant, refinery, and power plant all over the world who are operating their pumps for days and weeks against a closed valve, or a totally clogged downstream filter. Some operators leave pumps running long after the suction tank is drained and empty. These pumps are 0 percent efficient for hours, days, weeks, and months.

Of course the mysterious vibrations go up. This is the reason reliability engineers invest in vibration analysis for their pumps. (Now I’m rubbing your nose in it. But you knew that. Didn’t you?)

Pumps consume maybe 20 percent of the world’s available energy. Keeping these pumps at optimum efficiency is critical. If I were performing an energy audit, and making recommendations to save energy (money), I’d look first at pump operation and system design.

Show your customer how he or she can save 30–60 points of efficiency on each pump in the plant. Don’t waste his or her time talking about 2 percent efficiency savings. Wear rings and epoxy coatings are way down on the priority list.

Some industries like oil refineries, pharmaceutical plants, food production (soup, dairies, beer, vegetable oil) and municipal water distribution are pump intensive. Eighty percent of the monthly electric bill goes through the motors and pumps to move, mix, filter, heat, ferment, refine, strain, cool, and bottle liquid products.

The "bean counters" need to look seriously at system design and operator training. The engineers and operators, with some training and a few gauges, can turn all pumps into energy stars of efficiency. A good pump operator can compensate for inadequate system design and system upsets.

Remember, the driver (the operator) has the most influence on a car’s efficiency. The driver (operator) determines if a car is a high-maintenance car or a low-maintenance car. The driver determines the ultimate service life of a car.

If I were performing an energy audit at a power plant, refinery, hospital, chemical plant, or municipal water plant, I’d recommend that we look critically at pipe and process system design and pump operator training. With little effort and time, the pipe systems can be improved or modified so that all pumps run at their optimum efficiency with minimal operator intervention.

Cheap pumps are generally inefficient pumps. A high-efficiency pump can be 5–10 efficiency points better than a comparable cheap pump. A purchasing agent may think he saved his company $1,000 on a pump purchase and not realize that the electricity for the cheap pump will cost $4,000 more per year due to poor efficiency. The $1,000 savings on the invoice is a one-time savings. The $4,000 additional energy will hit the company every year the pump is in service. And the cost per kilowatt-hour will rise over time. Incorrect clearance on a pump’s wear bands can cost a pump maybe 2 or 3 efficiency points. This is not trivial but it is inconsequential compared to the energy savings of proper system design and operator training.

Our industry dedicates much effort, many words, and even more dollars into proper alignment and balance. Laser alignment and dynamic balance can recover (not improve) maybe 2 percent lost efficiency from misalignment and imbalance. But it can’t compare to proper system design and correct equipment operation.

I believe in lubrication. A lubrication program is vital. Inadequate lubrication is easy to improve. However, a pump operating on the extreme of its performance curve is 0 percent efficient even with the best, highest quality, synthetic grease or oil on the bearings. So why do we pay attention to lubrication and do nothing about inadequate system design or operation?

Ronald, this may be more information than you wanted. I perceived you were looking for some guidance to help with your recommendations after you conduct your energy audit on your client’s pumps. Good luck with the audit.

Larry Bachus, founder of pump services firm Bachus Company Inc., is a regular contributor to Flow Control magazine. He is a pump consultant, lecturer, and inventor based in Nashville, Tenn. Mr. Bachus is a retired member of ASME and lectures in both English and Spanish. He can be reached at [email protected].