Hi Larry,

I am a process engineer with an Indonesian petroleum company. I attended your pump course a few years ago. I have a question regarding sizing new pumps for a cooling water system.

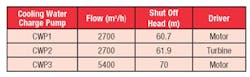

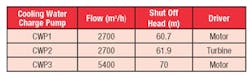

Our cooling water system supplies water via three pumps to the entire refinery. Two pumps are similar in head and flow. One of the twin pumps is driven by a fixed-speed electric motor. The other is turbine driven. The third pump is larger.

Some exchangers receive more flow than is required, while others are starved of flow. We need about 9,500m3/hr. of flow to satisfy all the users. Even though our pumps should in theory be able to supply this flow, our system does not allow this. We need to design a pump to supply more water at the cooling towers and then install another booster pump at the area where less flow exists.

What are the consequences of having pumps in parallel that have different heads? If I have to design another pump, will that have to be the same head as the other pumps? We were told that our pump heads are too low to go across the refinery. Does this mean that all three pumps need to be changed?

Lariesha N.

Process Engineer

Hello Lariesha,

Let’s do what we can by e-mail. I can schedule a visit if necessary. You asked three questions, beginning with:?

Q: What are the consequences of having pumps in parallel that have different heads?

It is always good when parallel pumps are identical twin pumps. When designed properly into the system, the system favors both pumps together. Both pumps will produce equal head and flow. Ideally, both pumps will operate at best efficiency.

However, mismatched pumps with different heads can operate together in parallel. Remember these points:

1. The smaller pump will only operate together with the larger pump when the system allows it to operate. Plot the system curve with the pump curves.

2. The system cannot favor both pumps together if the pumps are mismatched. Depending on the mismatch, one of the two parallel pumps (or both pumps) will be stressed. Therefore, design both pumps to operate on the extreme of the performance curve.

3. As you specify the pumps, specify the oversized shaft, double mechanical seal, oversized bearings, double-volute design casing, high-temperature lubricant, etc., to deal with stress from the system. Remember, if you don’t specify precisely what you need, purchasing won’t pay for it.

Plot the system curve with the unmatched parallel pumps. The system curve will show where and how the larger pump might deadhead the smaller pump. The system curve will show how the smaller pump might drag the larger pump into cavitation. The system curve will also show where both pumps will contribute head and flow together to the refinery.

Q: If I have to design another pump, should it produce the same head as the other pumps?

No. It is always nice when the pumps are identical but is not necessary.

Q: We were told that our pump heads are too low to go across the refinery—so does this mean that all three pumps need to be changed?

Not necessarily. You must clarify the complaint.

Your message to me says: “We were told that our pump heads are too low to go across the refinery.” Who told you? Did the design engineers tell you the pump head is too low? The design engineers should change the pumps if they determine that the pump head is too low for the system.

You are a process engineer. Did another process engineer report that the pump head is too low? These words don’t sound like process language.

A more realistic observation from a process engineer would be that the cooling or heat exchanging is inadequate across the refinery. The problem might be in the system and not in the pumps.

Maybe the system resistance is too high. The pump’s ability to cool and exchange heat is not reaching the other end of the refinery, and the equipment is running too hot. This is a more realistic complaint from a process engineer.

Besides, your own words support inadequate cooling” rather than low pump head. Among other things, you said: “… low cooling water velocities within our heat exchangers …”, “… total flow supplied is less than required …”, “… inadequate distribution …”, and “Some exchangers receive more flow than is required, while others are starved of flow.”

I would seek to clarify the complaint. Is the pump head definitely too low? This is a pump problem. Change the pump. Is the cooling inadequate across the refinery? This may be a problem in the system (pipes, elbows, valves, strainers, etc.). Modify and balance the system.

I hope these answers are adequate. I expect to be in your city later this year. Let me know, and I’ll schedule a visit to your refinery.

Good Luck with your Cooling Tower Pumps.

Regards,

Larry Bachus

You know how a roadmap or GPS will help you to walk or drive to an unfamiliar destination? Most maps indicate the fastest or shortest route, and even alternate routes, with points of interest along the way. Likewise, the system curve is the roadmap or GPS of your pipe arrangement.

My experience indicates that too many process and production engineers are unfamiliar with their system curves. System curves are not discussed in the university. Therefore, the engineer believes he really needs the vibration meter, oil analysis, or ultrasound to diagnose pump problems.

The system curve shows why and how your pumps overheat, go into cavitation, or suffer mysterious vibrations. The system curve also shows how to avoid these problems. More importantly, the system curve is quite easy to plot and understand.

We discuss system curves in detail in the Pump Guy lectures. We will be in New Orleans and Los Angeles later this year. For more details, see FlowControlNetwork.com/PumpGuy.

Larry Bachus, founder of pump services firm Bachus Company Inc., is a regular contributor to Flow Control magazine. He is a pump consultant, lecturer, and inventor based in Nashville, Tenn. Mr. Bachus is a retired member of ASME and lectures in both English and Spanish. He can be reached at [email protected].