(a.k.a. “The Pump Guy”)

Hey Pump Guy,

I need some advice. My team is looking at doing some simple pump and system Web calculators. Our goal is to build these calculators using some special server-side code so that folks can just copy a few lines of code and embed the widget-like calculators on their website.

Do you have any recommendations for calculators that would be useful for pump companies (manufacturers & distributors), as well as consultants? Here are the ideas that we came up with:

- Total Head Calculator

- Flowrate Calculator

- Pressure Drop Calculator

- Pipe Friction Loss Calculator

- NPSHa Calculator

- Viscosity Correction

- Unit Conversions (Head/Pressure Converter, Flow Converter, Temp Converter)

- Break Horsepower (BHP) Calculator

- Hydraulic Power Calculation (Using a combination of Flowrate, Head, Efficiency, SG, and Power (calculate the missing values)).

Thanks so much Larry, and take care!

Regards,

Justin J.

Hello Justin,

You probably know all the simple calculators and formulas. The Total Head, NPSHa, viscosity correction, head-to-pressure, pressure drop, and power formulas appear in most pump books, on the Internet, and in all university fluid mechanics textbooks.

The pipe resistance charts with friction and velocity losses are also available on the Internet and from most pipe and equipment suppliers. I don’t have anything new to add, except that I don’t often consult these charts.

For my work, the charts are mostly useless. I call the friction and velocity losses “guesstimations” — somewhere between a “guess” and an “estimate.”

I install and consult instrumentation when I do my work as a pump consultant. The pressure gauges and flowmeters will tell me the friction and velocity losses. The instrumentation also indicates where the pump is operating on the performance curve. I do this because you cannot see inside a pipe.

Apprentice pipefitters learn early in their career, “Don’t chase anything that falls into a pipe if you want to keep your fingers and hands.” Don’t chase a nut or a bolt, or a piece of gasket paper, or your watch, or your safety glasses, or your favorite wrench, or your dentures, or wedding ring. This rule is written into union agreements to protect the pipefitters, the company, and the insurers. This rule avoids lawsuits later. Some objects remain stationary in a pipe or elbow for years. And other objects will likely appear later in a downstream strainer basket.

You can’t look at the outside of a 700-ft run of 8-inch pipe and see if indeed the pipe is really Schedule 40 pipe. The run might include some sections of Schedule 80 pipe. So, do you want to “hope” the pipe-run is really Schedule 40 pipe? And what does the chart say about the resistance through that length of pipe? Do you want to believe a chart or calculator regarding velocity or resistance?

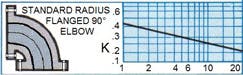

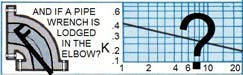

You can’t look at the outside of a 10-inch, standard-radius pipe elbow and see a long-lost pipe wrench stuck inside the elbow.

So, what is the actual friction loss through that elbow? Do you want to believe some chart or friction formula?

You can’t look at the outside of a length of pipe and see if the pipe is scaled with minerals on the inside diameter. Ten-inch water pipe eventually becomes 9-inch water pipe with scale and mineral deposits. So, what is the resistance through that length of pipe? Is this the time to “guestimate” the resistance?

You can’t stand on the floor next to the boiler in a power plant and look at the underside of a 16-inch overhead valve three stories up, and see if the valve is open, or partially open, or mostly closed. So, should you believe the operator? Or, believe some chart that proposes the theoretical friction loss through a totally open 16-inch feed-water valve?

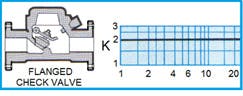

So, what is the resistance loss through that check valve? Differential gauges will tell me how much energy is lost through the check valve.

What about that basket strainer? Is the screen mostly clean or mostly dirty and clogged? Is the screen the original factory screen, or did the purchasing agent buy the screen from a pirate parts supplier? So, what is the friction loss through that basket strainer? Do you want to believe the chart? Differential gauges will tell me the actual energy hit through that strainer basket.

Consider a check valve. A published chart might show the theoretical resistance of a process check valve. However, how do you predict or measure the resistance of a spring-loaded check valve?

I was an engineering student back in the 1970s. I took Fluid Mechanics in 1973. I blindly believed the charts and my professor as I calculated the friction losses in a pipe system with elbows and valves.

The engineering students are excused and pardoned because they lack real-world experience. It is sad though that too many practicing design engineers never consider these issues as they crunch numbers in an effort to mate a pump into a dynamic pipe system.

Do you really want to know why your pumps are vibrating and overheating? Do you really want to know why your mechanical seals fail prematurely? Or, is it easier to blame the shop mechanics or the mechanical seal supplier for habitual mysterious pump and seal failures?

And that’s what I have to say about the formulas and calculators. In the real world, most of those resistance calculations are simply “guesstimations.”

Regards, Larry Bachus

All equipment failures can be attributed to:

- Inadequate Maintenance, or

- Incorrect Operation, or

- Inadequate Design, or

- A combination of these factors.

Larry Bachus, founder of pump services firm Bachus Company Inc., is a regular contributor to Flow Control magazine. He is a pump consultant, lecturer, and inventor based in Nashville, Tenn. Mr. Bachus is a retired member of ASME and lectures in both English and Spanish. He can be reached at [email protected].