Users are selecting magnetic flowmeters due to their accuracy and reliability. Magnetic flowmeters are highly accurate at a time when many flowmeter users are looking for high accuracy. And their reliability is rooted in their method of operation. Magmeters have no moving parts to wear out, and their use is backed up by decades of study and experience. They are among the most trusted meters.?

While the magnetic flowmeter market is a mature and stable one, there are some new product developments in the market that favor continued growth. One recent development is the advent of two-wire magnetic flowmeters. Two-wire meters typically cost less than four-wire magmeters and are becoming more popular with users.?

Another development is the growth of battery-operated and wireless magnetic flowmeters. Battery-operated magmeters have a similar appeal to data loggers and other open-channel flowmeters that are used in remote locations where they may only be checked periodically. Applications include water distribution, irrigation, agriculture, and networking. While only a limited number of suppliers currently offer battery-operated or wireless magmeters, expect continued growth in this niche area of the magnetic flowmeter market.

In terms of more mainstream developments, suppliers are continuing to provide innovative solutions in the area of liner types. The two most popular types of liners for magnetic flowmeters are PFA and PTFE, followed by hard rubber. KROHNE, which is one of the few companies that offers two-wire, four-wire, and wireless/battery-operated magnetic flowmeters, uses Rilsan® as their newest liner type. KROHNE claims that Rilsan provides their battery-powered magmeters greater resistance to high temperatures and chemical exposure because this liner is molecularly bound to the inner diameter of their flowmeter, unlike the typical rubber liner. KROHNE also says that the liner is harder and more resistant to coating, which makes the liner more serviceable in water extraction, irrigation, and other agricultural applications where clean water conditions cannot be assured.?

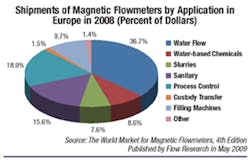

Just as differential-pressure flowmeters have traditionally been the flowmeter of choice in the United States, so magnetic flowmeters seem to be the flowmeter of choice in Europe where the top three suppliers of magnetic flowmeters are located and where food processing and pulp & paper industries are prevalent.