Pressure measurement is one of the oldest, most common means of process control: It is tried, tested and proven with good reason. Pressure technology is versatile because it can measure level, density and interface, and users can choose a measuring cell material that best suits their processes depending on measurement range, process temperature, hygienic requirements, etc. The most popular cell material is metal, but ceramic is emerging as a cell material to measure corrosive liquids in challenging applications. Still, ceramic cells are relatively new to the market and users may be unaware of their benefits.

1. Abrasion resistance

By nature, ceramic is abrasion-resistant. The material’s tight, dense matrix makes a ceramic diaphragm 10 times harder than stainless steel. This extra strength is advantageous because it makes ceramic better-suited to withstand harsh environments, including slurries, mines and paper production – any application where liquid is used to move solids. In these applications, process material often contacts pressure diaphragms, resulting in damage to the cells. This is not an issue with ceramic cells because surface scrapes do not leave marks, scratches or indentations. If product builds up on its surface over time, users can simply scrape it off with a hard metal object without harming the ceramic cell, making it suited for use in slurries that tend to disintegrate metal diaphragms.

2. Longer-lasting dry cells

Ceramic cells are known as dry cells, meaning they do not use filling oil to measure pressure. In typical pressure sensors, this oil acts as a transfer medium to move the pressure on a diaphragm to the measurement cell behind. To allow the oil to transfer, the metal used for diaphragms is thin and fragile, which leads to quick wear and tear. When metal diaphragms fail, oil contaminates process material and users may have to discard an entire batch. Such waste is costly and unsustainable. Making a bad situation worse is the fact that users often do not know failure has happened until it is too late. By the time anyone is aware a problem exists, the process is contaminated and the metal diaphragm is ruined.

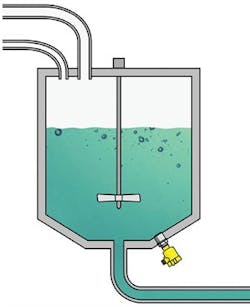

Conversely, ceramic cells use capacitive measurement at the point of pressure and do not rely on oil to move the pressure value. This means thin material that wears easily is not necessary, and it also means the process will never be contaminated with filling oil. This eliminates the risk of wasting an entire batch and replacing damaged pressure sensors. Additionally, removing filling oil does away with temperature reduction for the cell when working in a vacuum environment like one would find in a distillation column or separation tank. A dry cell is a trustworthy cell.

3. Reduced hydrogen permeation

Chemicals do not corrode ceramic cells, meaning they can be mounted flush with the process material.

When hydrogen molecules penetrate through metal diaphragms, they get trapped and react with the filling oil. This reaction causes an expansion, which falsely indicates increasing pressure. To minimize hydrogen permeation, metal diaphragms are usually coated with gold or another dense, pliable material. This slows down the transfer of hydrogen molecules from the process to the oil filling behind the diaphragm, but hydrogen transfer still happens. The dense lattice of a ceramic cell also slows down the permeation of hydrogen molecules. However, since no oil filling is present behind the diaphragm, no effect occurs on the pressure reading. In pressure cells, ceramic is worth more than gold.

4. Minimal drift

Drift is the gradual offset from calibration after measurement cycles. Over time, pressure sensor drift can have a “death by a thousand cuts” effect since it distorts measurement accuracy and reliability. Drift for metal diaphragms can appear quickly as the thin metal fatigues and does not return to true zero. This drift is corrected by frequent field “rezeroing,” industry shorthand for offsetting a sensor’s deficiencies by choosing a new value for zero. Operators should not have to exert this extra effort and mental gymnastics to compensate for their equipment, but they do because they have never had a choice. Drift is an unfortunate fact of life for pressure measurement with metal measuring cells.

Ceramic cells are drift-free because they are limited in motion, creating less fatiguing and fewer required routine calibrations. This means that repetitive cycles and temperature extremes have a minimal effect on the life of the cell membrane. In turn, operators enjoy an extended cycle for routine maintenance and have no need for rezeroing.

5. Minimal product compatibility issues

In contrast with metallic cells, ceramic cells are compatible with most process materials. Ceramic’s dense makeup makes it the ideal cell material for a variety of process media because it does not corrode like metal does. This is welcome news to applications that measure everything from saltwater to acidic solutions because they do no damage to the ceramic cell. Additionally, expensive metallic-like tantalum is required for certain chemical applications – chlorine, for example – whereas ceramics are compatible with most chemicals.

6. High overload resistance

With minimal space between the diaphragm and the body of the ceramic cell, the diaphragm bottoms out on the base when pressure exists beyond the rated span. When that pressure is removed, the cell diaphragm returns to its original position and to full operation without recalibration. This means the cell can handle elevated overpressure beyond its span without permanent damage or offset. Even with ceramics, overload protection varies from cell to cell. To learn more, users should contact their pressure instrument manufacturers.

7. Temperature output

Some manufacturers offer ceramic cells with optional temperature measurement that can be output as a standard digital HART variable or assigned as the main or secondary 4-20mA output. This additional measurement may allow users to avoid the expense of a remote temperature device in the process. It is important to note that this temperature value is usually used internally for thermal shock compensation and is not available for process compensation.

8. Detection of small pressure changes

To detect a pressure change with a metal measuring cell, oil must move through a diaphragm. That holds true even when the measurement range is small, i.e., a maximum of 25 millibar. Such a short distance requires a large diaphragm to register the pressure change. However, increasing the size of a metal diaphragm is risky because metal cells get weaker and wear out faster as they get larger. Since no oil moves in a ceramic cell, small changes can be detected without altering the size of the pressure transmitter.

Conclusion

This is not to say it is time for users to swap out all of their installed pressure instruments for new ones with ceramic cells. Metallic measuring cells have their place. If a user thinks, “I’ve never had a problem with my pressure sensor and it has a metallic measuring cell,” that is great. By all means, if metal works, keep it. Do not change for the sake of change. However, taking the benefits of ceramic in sum, one can draw a few conclusions about where users might want to consider switching to pressure instruments with ceramic measuring cells.

Ceramic’s abrasion resistance and dense makeup make it a logical fit for harsh applications including slurries and mines, and for measuring corrosive product. Ceramic’s high overload and temperature resistance make it a viable measurement cell option for tracking movement in pipelines, measuring pressure and level in pressurized batch vessels, and monitoring negative pressure in distillation columns. In difficult applications in which the measurement cell must be kept from the medium, ceramic is up to the task.

Jeff Brand is a product manager at VEGA Americas responsible for pressure, switching and capacitance probes. He has more than 12 years of experience with industrial automation and sales, nine of which have been spent with VEGA Americas. Brand has a background in engineering mechanics, automation and instrumentation.