Businesses that make discharges into rivers, smaller watercourses, and the sea are usually required to monitor flow to meet local requirements and protect the environment and human health. Accurate measurement of these flows is not only important for local compliance—since most wastewater treatment companies base their charges on volumetric discharge—submitting inaccurate data could have a significant impact on a company’s operating costs.

Accurately Measuring Flow

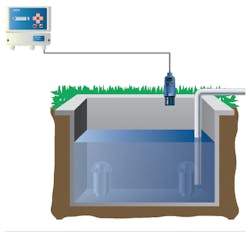

Open channels are widely used by industrial companies for the discharge of wastewater. The most common method of measuring flow through an open channel is to measure the height or head of the liquid as it passes over an obstruction—for example, a flume or weir in the channel. There is a specific relationship between the height of inlet water and the flowrate for every open channel that is free flowing through a specific controlled metering structure. This means that for any given inlet height there will be a corresponding flow. By plotting this relationship, the flow can be determined by accurately measuring the water level or head using a level sensor.

To satisfy the needs of regulatory bodies for continuous, accurate, and reliable flow data, electronic measuring devices are being increasingly specified for the measurement of water level. These have become the instrument of choice as they provide higher accuracy, improved reliability, and reduced maintenance. Level sensors based on ultrasonic technology meet these requirements and are being increasingly deployed for the measurement of flow in open channels.

Uncertainty In Measurement Systems

In open channel applications, even with the best equipment and robust maintenance regimes, regulatory authorities accept that there will be an uncertainty of measurement. The regulatory authority typically establishes uncertainty limits. For example, in the UK the target is +/- 8 percent uncertainty for the total daily volume of effluent discharged.

To achieve this figure, consideration must be given to all components of the flow measurement system, including the manufacture and installation of the primary devices (flumes and weirs) to the relevant standards, installation, and commissioning of level measurement devices and the flow calculation.

Inaccuracies in an open-channel flow system can be caused by calibration faults, incorrect installation, incorrect construction, super critical flow in weirs, subcritical flow in flumes, floating debris, environmental conditions, poor computational methods, and the inability of the measurement system to respond to rapidly changing flowrates. In open-channel installations, measurement errors can introduce significant inaccuracies and these errors can be categorized into either systematic or random errors.

Systematic errors are repetitive errors that are repeated in each measurement. These can be caused by a calibration error or incorrect flume dimensions, etc. Once identified, these errors can usually be eliminated or reduced.

Random errors are much more difficult to identify. They are caused by unpredictable or random events—for example, debris underneath the sensor or the blockage of a V-notch.

In open-channel flow measurement, most random errors directly affect the level in the channel or weir, which can have a considerable effect on the total accuracy. A good understanding of primary device construction and installation, and good housekeeping practices will help to keep these errors to a minimum.

Flumes are available in all shapes and sizes and must be dimensionally compliant—usually in line with an appropriate standard—for example, BS or ISO.

Maintenance is a major consideration, and cleanliness is important in achieving accurate flow data. If sediment or bio growth forms on the sides of the approach channel and flume cheeks, the flowmeter will invariably read high. This would have a significant impact on industrial dischargers who usually pay for the volumetric discharge based on cubic meters or per 100 gallons. A high flow reading means excessive charges for the business.

The Importance of Accurate Level Measurement

When determining the uncertainty of flow measurement in an open-channel application, the measurement that has the greatest effect is the upstream level measured in the approach channel. It is therefore very important that the level measurement device used is accurate, reliable, and unaffected by environmental changes, such as temperature.

The latest generation ultrasonic level transmitters have been developed specifically for use in open-channel flow measurement and provide highly accurate results. The ultrasonic sensor is mounted above the flow stream and transmits a sound pulse that is reflected by the surface of the liquid. The time required for a pulse to travel from the transmitter to the liquid surface and back to the receiver is used to determine the liquid level.

However, since the speed of sound in air varies with its temperature, it is necessary to compensate for factors such as the weather and heat gain from sunlight. For example, a change in air temperature from 20 C to 22 C would translate into a 1.2 cm (~0.5”) change in distance to surface value. Depending on the size and shape of the channel, this error could have a significant effect on calculated volume flow.

To overcome this problem, some modern ultrasonic transmitters are capable of automatically compensating using a remote temperature sensor connected directly into the transmitter. This is positioned above the liquid surface to accurately monitor air temperature.

The accuracy of flow measurements can also be affected by variations in surface level caused by surface turbulence or a sudden variation in flow that cause wave effects. In order to take account of these changing conditions, a rapid ultrasonic pulse rate is required. For example, the ultrasonic pulse rate of certain modern ultrasonic transmitters is 1 per second (user configurable 0.5 to 2 seconds), enabling the tracking of changing flow profiles as they occur.

The resolution of the measuring device is also very important in open-channel applications. Resolution defines the system’s ability to detect and respond to small changes in the open channel level. For example, a level error of just a few mm in the inlet height could result in a significant totalized flow error. A transmitter with a resolution of 1 mm ensures that errors due to small changes in channel height are minimized.

To confirm the accuracy of the results provided by the level transmitter, it is good practice to install a reference target for the transmitter. This provides both a rigid structure to mount the instrument and incorporates a retractable target plate to produce a reference reading at a pre-determined height above the datum level. This is usually set during commissioning using an optical or laser level, which enables the end user to perform easy checks on the system to ensure the readings are correct.

Data Recording

To convert the level measurements into flow, the digital data from the level transmitter is sent to a flow logger. This combines the characteristics of the flume or weir with the level data and performs the on-board flow calculation and integrates flow to provide cumulative and daily totals so that dischargers can be charged based on their actual flow volumes.

For example, some modern ultrasonic level transmitters will accept a 4-20mA or HART transmitter input. They can be pre-programmed with standard volumetric and flow equations to convert a level signal into contents or flow.

Regulatory authorities usually require historical data of flow volumes, so the ultrasonic level transmitter should be able to store flow data in a form that can be downloaded as an ASCII file, saved as a CSV file on a PC, and imported into Excel for generating custom reports.

Meeting the Need for Continuous Monitoring

To meet the regulatory requirements for emissions monitoring of discharges, many companies must continuously monitor their emissions to meet quality requirements.

The most common method of measuring flow through an open channel is to measure the height (or head) of the liquid as it passes over an obstruction. The requirement for accurate and reliable continuous measuring devices has seen the growth in the use of ultrasonic level transmitters for emissions monitoring applications.

Ultrasonic level transmitters do not require any maintenance and they have been developed specifically for use in open-channel flow measurement. Temperature sensors are used to compensate for changes in air temperature. When used with a flow logger, ultrasonic level transmitter can be employed to provide historical data in a format that can be used to confirm compliance with local requirements.

Peter Ward is a senior product manager for Ultrasonic Level Instrumentation with Mobrey Measurement, Emerson Process Management, based in Slough, UK. Prior to Mobrey, he worked for GEC Elliott Process Instruments involved with design of level and flow control systems, and later Arkon Instruments, Ltd., specializing in open-channel flow. Mr. Ward has more than 35 years experience in the Water & Wastewater industry and has been an MCERTS Inspector (Monitoring Certification Scheme) for flow measurement on behalf of the UK Environment Agency.