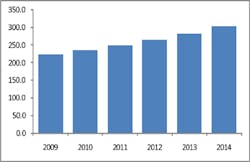

The worldwide market for vortex flowmeters totaled $224 million in 2009, according to a report by Flow Research, titled The World Market for Vortex Flowmeters, 4th Edition. Flow Research says demand was primarily driven by the versatility of vortex meters, which can readily measure liquids, steam, and gas. In addition, the American Petroleum Institute’s approval of a standard for using vortex flowmeters in custody transfer has continued to push sales upward. The study also finds that new companies are entering the vortex flowmeter market and existing single-variable vortex providers are entering the multivariable market.

Flow Research projects a compound annual growth rate (CAGR) in revenues for the total worldwide vortex flowmeter market of 6.3 percent through 2014. By 2014, the vortex flowmeter market is projected to reach $303.7 million. The most rapid growth is occurring where new process plants are being built, primarily in China, the Middle East, and in developing Asian countries.

“Vortex meters withstood the economic downturn better than most other new-technology flowmeters because of their ability to measure steam as well as liquids and gas,” says Jesse Yoder, Ph.D., president of Flow Research. “Magnetic flowmeters cannot measure steam flow, and Coriolis and ultrasonic flowmeters are just beginning to be used for this purpose. Not only can vortex meters tolerate high process temperatures and pressures, but they can also measure steam flow at varying velocities. This gives them a leg up in a variety of industries, including oil & gas.”