By Dick Laan, Ultrasonic Flow Product Manager, and Rick Lowrie, Water & Wastewater Industry Manager, KROHNE Inc.

As interest in biogas grows, more attention is being paid to measuring biogas flow, which has long been a problem area in process measuring technology. High water and carbon dioxide (CO2) content make biogas a demanding medium and a difficult measuring task, but a new generation of ultrasonic flowmeters makes biogas measurements stable and manageable.

Biogas Energy Sources On The Rise

According to the U.S. Biogas Council, the U.S. has about 2,000 sites producing biogas, with another 12,000 called ripe for development.[1] Biogas is being promoted in the U.S. as an alternative to conventional fuels as it increases energy security and produces fewer greenhouse gas emissions, in addition to other environmental and economic benefits. [2]

As an illustration of where the U.S. market may be heading, Europe has more than 10,000 operating digesters. According to Germany’s Biogas e.V. professional association, well over 1,000 new biogas plants were built in 2011 in Germany alone. Today, more than 7,000 installations generate a total electrical power of more than 3000 MW and rising. Within just a few short years, biogas has thus reached a share of around 3 percent of the total energy consumption in Germany.

READ ALSO: 5 Key Insights On Flowmeter Calibration from Leading Industry Experts

Traditionally, biogas in these plants is a product of the fermentation of sludge from wastewater treatment plants and landfills. Nowadays, other bio feedstock such as waste from cattle farming and other agricultural operations are also used to produce biogas. This gas is generally used in combined heat and power plants to directly generate electricity and heat using a gas engine. More and more, biogas is reworked to grid quality to supply into the gas grid. Biogas is also being used as an alternative vehicle fuel.

Measuring Methane Content Crucial to Successful Operations

When it comes to using biogas, knowing the methane (CH4) content is crucial. Operating gas engines in a combined heat and power plant smoothly and efficiently can only be guaranteed if the biogas has the right minimum methane content. The plant operator must thus be familiar with the composition and quantity of the biogas used.

This is especially true when biogas deliveries to gas grid operators are used in custody-transfer applications. Since the methane content of biogas can vary greatly, plant operators rely on continuous and reliable information about the biogas. But this is exactly what creates a great challenge for many operators today. Generally, multiple measurements may be taken in a biogas plant, for example before and after the storage tank. However, successfully mastering the measuring task is no mean feat. This is largely due to the demanding measuring parameters associated with biogas applications.

Difficult Measuring Parameters

Depending on the bio feedstock and process, biogas contains only about 50-70 volume percent methane. The remaining portion is made up of 30-50 volume CO2 and smaller amounts of oxygen (O2), hydrogen sulphide (H2S), and nitrogen (N2). In addition, the biogas can contain up to 5-6 volume percent free liquid water, since the biogas is saturated with water during fermentation, which then gets into the pipeline following cooling down and leaving the fermentation tank.

When dissolved in water, the H2S creates a corrosive solution in the pipeline. In addition to high moisture, resistance to corrosion must also be taken into consideration when selecting a measuring device. Bacteria can also be deposited in the flowmeter during biogas measurement.

The temperature ranges from slightly above the ambient temperature to 122 F and the pressure is typically 20-25 inches H2O. In principal, however, process conditions can vary greatly. For example, when measurement is done directly after the fermentation sudden temperature drops can occur when new sludge is fed into the fermentation tank. In addition, the measurement may not cause any loss in pressure. Depending on what is required, it pays for the measuring devices used to cover the widest possible measuring range. Most biogas plants, in the wastewater industry for example, have a pipeline diameter of 2” to 8”. Larger sites for biogas production can also require larger nominal sizes (12” to 16”).

Flow measurement technology has attempted to meet these special measurement requirements with a variety of different measuring methods, but a satisfactory solution to the measuring task had yet to be found. For example, orifice plates have proven themselves to be completely unsuited to biogas measurements under the outlined pressure conditions, because they cause pressure losses and may thus significantly interfere with the process.

The conditions for using the vortex flowmeter are in turn very limited for measurements at low flow velocities. Thermal mass flowmeters are still the most commonly used measuring devices in the biogas industry, but these measuring instruments also suffer from a considerable handicap: water in the biogas line considerably restricts its performance.

Based on their design, ultrasonic flowmeters have always been particularly well suited to biogas applications because they guarantee a full transit without loss of pressure or any negative effect on the flow and they can cover a wide measuring range. However, in the past they have had to deal with high water content. In addition, the high CO2 content typically present in biogas flows also had a negative effect on the measuring stability, since CO2’s molecular structure can significantly decrease the dispersion of the ultrasonic signals. In addition, the cost to purchase these devices is still comparatively high, which often made the use of ultrasonic flowmeters unattractive.

State-Of-The-Art Ultrasonic Flow Measuring Technology for BiogasThe measuring instrument, which functions according to the time-transit differential method, guarantees flow measurement with a high degree of long-term stability regardless of the gas composition. The solution is maintenance-free and immune to deposits. Thanks to its special signal converter design, the OPTISONIC 7300 also features considerably higher signal strength. The NACE-approved Grade 29 Titanium transducers provide excellent corrosion resistance against H2S. An enhanced digital signal processor (DSP) also allows for better detection of small acoustic signals strongly dampened by high CO2 content. Meter construction also eliminated any effects from water on measurement. The device does not have such limitations as regular recalibrations, pressure loss or flow range restrictions. In addition, to make various measurements comparable, the standard volume can be measured based on temperature and pressure inputs to the OPTISONIC converter.

Experience has shown that the device can perform stable and accurate biogas measurements, exactly what plant operators need to ensure the viability of their biogas operations.

Calculation of Methane Content Using OPTISONIC 7300

The measuring device features an integrated calculation of the methane content, which as noted is critical to efficient gas engine operation when biogas is used. The calculations shown are taken from an actual wastewater treatment plant application example.

The molar mass (M) of a gas is determined according to the following formula

γ = Adiabatic index, pre-set value into the flowmeter electronics; an average value of 1.31 is entered for the CO2/CH4 mixture.

R = Molar gas constant, approximately 8.3145 J mol-1 K-1.

T actual = Gas temperature in Kelvin, can be measured via a 4-20 mA input on the converter

VoS = Sound velocity of the gas

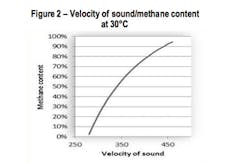

Figure 2 shows the velocity of sound/methane content at 30 C.

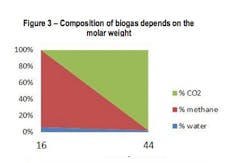

The methane content can be calculated from the molar mass, considering the following:

The molar weight of CO2 (44)

The molar weight of methane (16)

The molar weight of water (18)

The amount of water in the gas depends on the temperature. For a water-saturated gas the amount of water is known. Figure 3 illustrates that the composition of biogas depends on the molar weight.

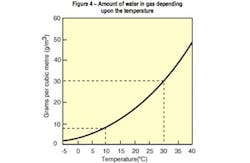

The methane content is measured with an accuracy of 2 percent (including uncertainty of the temperature measurement of 1 percent). Figure 4 illustrates the amount of water in a gas depending on the temperature.

The advancements of new flowmeters come at an opportune time, just as the growing importance of biogas as an energy source has been crying out for reliable flow measuring devices.

References

- Current and Potential Biogas Production, American Biogas Council, http://www.americanbiogascouncil.org/pdf/biogas101.pdf, retrieved 8/12/13.

- Renewable Natural Gas (Biogas), Alternative Fuels Data Center, US Department of Energy, http://www.afdc.energy.gov/fuels/emerging_biogas.html, retrieved 8/12/13.