A major power generator on the East Coast was having a serious problem with premature tube failure in the feedwater heater in one of its 400-megawatt pulverized coal plants. The company has asked not to be identified, but says it thinks the nature of the problem may be widespread and would like to share the solution with the rest of the industry.

“We were getting hot spots in the water wall,” says Tim, the plant’s chief engineer. “We were pretty sure this was contributing to the tube failure, and maybe the only cause. We could measure the temperature at various spots on the water wall easily enough, but we thought the problem might be caused by inconsistent water flow, so what we needed was to find a way to measure the flow of the return water.

However, there were two problems with measuring the water flow. The first was that the company didn’t want to cut into the pipe to generate the flow measurement. The second was that the return water was condensed from steam and under pressure, so the pipe temperature was around 650 F.

In search of a solution, Tim went online to see what was available and found a clamp-on ultrasonic meter, made by FLEXIM, that was capable of measuring flow at up to 750 F. “I had always heard that clamp-on ultrasonic flowmeters could not retain contact in high-heat applications,” Tim says.

A High-Heat Solution

“Depending on the meter, the gels or pads used for acoustic coupling between the ultrasonic transducers and the pipe have a limited temperature tolerance,” says Izzy Rivera, service manager for FLEXIM. “Also, high temperatures accelerate the aging of the transducer’s piezo elements and reduce their operating life.”

Rivera says FLEXIM’s WaveInjector transducer-mounting fixture is designed to combat these factors. It allows the transducer to be mounted at a safe distance from the pipe, while still maintaining accurate readings. A clamp-on transducer mounted directly on the pipe can only operate up to around 400 F. The WaveInjector utilizes a mounting structure that removes the transducer from the pipe and positions it on waveguide plates. It also enables a set of standard transducers to operate accurately at temperature ranges from -256 F up to 750 F.

How Transit-Time Ultrasonic Meters Measure Flow

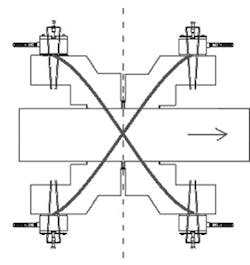

Transit-time ultrasonic flowmeters exploit the fact that the transmission speed of an ultrasonic signal depends on the flow velocity of the carrier medium. Like a swimmer swimming against the current, the signal moves slower against the flow than with it.

When taking a measurement, the meter sends ultrasonic pulses through the medium — one in the flow direction and one against it. The transducers alternate as emitters and receivers. The transit time of the signal going with the flow is shorter than the one going against. The meter measures transit-time difference and determines the average flow velocity of the medium. Since ultrasonic signals propagate in solids, the meter can be mounted directly on the pipe and measure flow non-invasively, eliminating any need to cut the pipe. Also, with new technology, it can be isolated from an excessively hot environment and still deliver accurate data.

Initial Problems

The six pipes that were being measured were 14-inch diameter, with inch-and-a-half thick walls. They ran 150 feet straight down from the steam drum. “We installed the WaveInjectors and the ultrasonic meters right near the top where the six down comers come out of the drum,” says Tim. “This made sure the meters were easily accessible, but after the meters were installed, we got no signal, just a lot of noise in the liquid.”

“We went out to see what was wrong,” says Rivera. “We investigated and came to the conclusion that they had air in the liquid. We suggested that the water level in the steam drum is too low, only about a couple of inches, and that caused a vortex as it drained into the down comers introducing air into the mix.” Rivera believed the introduction of air made the fluid a two-phase liquid, which the meters couldn’t read. However, management was convinced there was no air in the mix, which meant the only alternative was to pull the WaveInjectors and use the meters to measure flow only when the system was on shutdown.

Finding a Flow Solution

“At first we didn’t think air was an issue,” says Tim. “Then, during a shutdown, we raised the level in the drum to about 20 inches at a much lower temperature than the typical 650-700 F.” The temperature was actually down to about 120 F. The higher water level did away with the noise and the meter was able to accurately measure flow. “[Only] now we couldn’t measure flow at the elevated pressures and temperatures we wanted to when the system was operating,” says Tim. However, at the lower temperatures it was possible to use the pump curves and extrapolate from that temperature up to the operating temperature. “This helped us determine what we needed to do to solve the tube failure problem,” says Tim. “It wasn‘t ideal, but we were able to figure out the correct flows to eliminate the hot spots, repair the damaged tubes, and install the correct orifices.”

The tubes that come out of the mud drum have different orifice sizes, and some of the orifices were literally gone. Some of the ends of the tubes were eroded away over the years, so some of them had literally the end of the tube for an orifice instead of an orifice. The ends of the tubes were cut, and new ends were welded on with new orifices, and the flow was distributed based on the temperature reading in the walls. “We had temperature readings at different locations in the water wall and the extrapolated flow measurement,” Tim says. “We knew where we had some elevated temperatures, and then we were able to determine the correct orifice sizes and change them when we were off line. It gave us a good idea of how to more evenly distribute our flows and therefore our temperatures.” As a result, the company was able to protect waterwalls better and increase tube life.

Successful Installation

A year passed, and the cooler measurement at the lower temperatures made Tim realize that the low water level in the steam drum was part of the problem.

Tim figured that on the down stream side of the feedwater pumps the increased pressure could collapse, enabling more accurate measurements. FLEXIM ran a test, putting the WaveInjectors and the meters on the line in the basement near the entrance to the other drums at the discharge side of the pumps. The test worked, but on only two of the six pipes. It was agreed upon to raise the water level in the steam drum to 10 inches, which enabled accurate flow readings on all six pipes. It took a while, but the solution Tim was looking for was ultimately achieved.

“We now think the air in the line probably had something to do with the hot spots,” says Tim. “But the flow not being distributed properly was also a cause.” Of course, the heat transfer’s not as good where you have air in the line. Now that the tube and flow problems on the unit have been resolved, the company plans to move forward with a similar solution for a sister unit. “We’re sure, with what we’ve learned, we will be able to get accurate flow readings right away,” says Tim.

Jack Sine is a freelance writer specializing in power, chemical and HVACR industries. He can be reached at [email protected] or at 845 831-6578.

Izzy Rivera is service manager for FLEXIM, a manufacturer of clamp-on ultrasonic flow measurement devices. Mr. Rivera can be reached at [email protected].

www.flexim.com