Gas flow measurement is becoming more important as oil prices continue to stay high and as environmental concerns mount about alternatives to natural gas, such as coal and nuclear power. Natural gas is cleaner burning than oil, and it is also less expensive. Coal as a power source is inexpensive, but it is difficult to handle the pollutants that coal creates. Nuclear power has some major advantages, but many people do not trust it due to the potential for dangerous nuclear accidents.

Technologies like solar and wind power are attractive alternatives to fossil fuels; the problem with them is that they are still quite expensive because they are in the early stages of development. The price of alternative energy solutions will come down as more research and development is done, and as more products are brought to market. But this could take a number of years. In the meantime, the world is likely to rely on oil, natural gas, coal, and nuclear energy for the large majority of its power.

Many people are seeing natural gas in a new light today because new technologies have been developed that make it possible to extract natural gas in new locations. Shale gas is part of this story, and while there is concern over the impact the hydraulic fracturing process employed during shale gas drilling is having on drinking water supplies near drilling sites, the energy potential represented by shale gas in the United States is significant. In addition, new natural gas finds have expanded available reserves. According to current estimates, today the world has enough natural gas reserves to last from 50 – 75 years at a time when oil supplies are diminishing. As a result, many believe natural gas can potentially serve as a clean-burning, long-term bridge to renewable forms of energy.

In this context, it is worthwhile to take a look at the advantages and disadvantages of the main traditional technology flowmeters used to measure gas flow — differential-pressure (DP), positive-displacement (PD), and turbine flowmeters.

RELATED: Pros & Cons of New Technology Flowmeters for Gas Flow

Differential-Pressure Flowmeters for Gas Flow Measurement

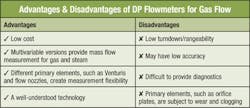

Differential pressure (DP) is a mainstay for low-cost gas flow measurement. Despite their limitations, many companies still trust DP flowmeters, particularly when used with orifice plates, to measure flow where accuracy is not at a premium.

Over the past several years, pressure-transmitter suppliers have released a number of new products with advanced features. These features promise higher accuracy, greater reliability, enhanced diagnostics, and more advanced communication protocols. In fact, a Colorado company called DP Diagnostics LLC, has developed what it says is the first-ever diagnostics tool for differential pressure flow measurement systems.

The promise of greater reliability is perhaps the strongest driving force behind improvements in pressure transmitters, including differential-pressure transmitters. While some pressure products may have a higher initial purchase price, end-users cite a number of reasons for shifting to higher-performing products. These include the need to conform to regulatory requirements, the need for reliability, a desire to standardize pressure products, and the need to do custody transfer. End-users seem willing to pay for higher performance, although this varies with application and with features.

Multivariable DP Flowmeters

The use of multivariable flowmeters has been growing substantially over the past several years. Several new companies have entered this market, including ABB, Invensys/Foxboro, and Yokogawa. Multivariable DP flowmeters measure more than one process variable, usually differential pressure and/or pressure and temperature. Many of them incorporate a pressure and a temperature transmitter into a single device, making it unnecessary to purchase these products separately. Multivariable DP transmitters are mainly used to measure mass flow, and they are primarily used for steam and gas flow measurement.

Like other DP flowmeters, multivariable DP transmitters require a primary element to create the restriction in the flowstream that enables the DP flow measurement. They can be used with orifice plates, Pitot tubes, Venturis, flow nozzles, and other primary elements. They are increasingly popular as end-users seek to reduce costs, as well as to measure more flow of steam and gas. Multivariable flowmeters also provide more information about the process, and this is another attractive feature.

One main advantage of DP flowmeters is their low cost. Orifice plates are quite inexpensive and can be installed with a DP flow transmitter to create a flow measurement. DP flow is one of the oldest flow technologies, and it is the most studied and best understood type of flowmeter. The American Gas Association (AGA) issued AGA-1, its first standard for the use of DP flowmeters for flow measurement in 1930. Parallel approvals did not come until 1981 for turbine meters and 1998 for ultrasonic meters. Disadvantages of DP flowmeters are that some primary elements, such as orifice plates, are subject to wear, and they typically have low turndown ratios. Orifice plates can also be subject to clogging if there are impurities in the flowstream.

Positive-Displacement Flowmeters for Gas Flow Measurement

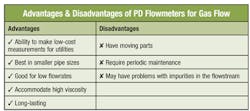

Positive-displacement (PD) flowmeters are the workhorses of today’s flowmeter world. They perform many important flow measurements that many people take for granted. For example, positive-displacement meters are widely used for billing applications for both water and gas.

Even though they face stiff competition from new-technology meters in some segments, PD meters still remain the best solution for certain applications. The PD market is so large that, like differential pressure flowmeters, PD meters benefit from the advantages of a large installed base.

Positive-displacement meters are used as billing meters to measure the amount of gas used in houses, commercial buildings, and industrial plants. Industrial plants, such as chemical, food processing, and pharmaceutical plants, also use PD meters for billing purposes. These meters are different from the meters used to measure gas as part of the manufacturing process.

Many of the PD meters used for gas utility measurements are diaphragm meters. However, technology improvements are occurring within the PD gas flow market. Rotary PD meters are replacing the older-style diaphragm meters. These newer rotary meters are smaller and lighter than diaphragm meters. In some cases, when customers take a diaphragm PD meter out of service, they replace it with a rotary PD meter. Rotary meters represent a newer technology, and they allow end-users to upgrade their measurement capability while staying within the class of PD meters. Rotary meters are also used for non-utility gas flow measurements in industrial environments. One company that makes both diaphragm and rotary meters is Elster-Instromet.

PD meters for gas applications face some competition from turbine flowmeters. However, PD meters are mainly used for the smaller pipe sizes, and most PD meters for gas applications have sizes somewhere between 1.5 inches and 10 inches. Turbine meters, by contrast, perform best with steady, high-volume flows. For this reason, turbine meters are more likely to be used for pipe sizes above 10 inches. This is also the range where ultrasonic meters excel. While ultrasonic, turbine, and PD meters overlap in the four-inch to 10-inch size range, PD meters still have an advantage in the lower sizes. Low flowrates are not a barrier to PD meters. For this reason, PD meters will continue to be used in the smaller line sizes to measure gas flow.

Besides doing well in measuring low flowrates, positive-displacement flowmeters also excel where many other flowmeters have difficulties, such as in measuring high viscosity liquids. In addition, they provide a very cost-effective solution for utility applications that require low-cost meters that last for many years. The main change occurring here is that automated meter reading (AMR) systems now allow meters to be read from a remote location.

Turbine Flowmeters for Gas Flow Measurement

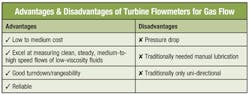

Turbine flowmeters still remain a viable and popular choice for measuring gas flows. They excel at measuring clean, steady, medium-to-high-speed flow of low-viscosity fluids.

There are several reasons why turbine meters will continue to maintain their wide usage for gas flow applications. One is that turbine meters have a significant cost advantage over ultrasonic meters, especially in the larger pipe sizes. Their price may also compare favorably to DP flowmeters, especially in cases where one turbine meter can replace several DP meters. Users who are already familiar with turbine technology and don’t want to spend the extra money required to invest in a new technology are likely to stay with turbine meters.

Secondly, turbine meter suppliers are making technology improvements to make turbine meters more reliable. Many of these improvements involve making the moving parts more reliable. By making ceramic, sapphire, and ruby ball bearings that are more durable than hard carbon, suppliers add significantly to the life of the bearings. This is important, since some customers select new-technology meters over turbine meters because turbine meters have moving parts. Other recently introduced improvements include bi-directional flow, self-lubrication, and significantly reduced pressure drop.

The chief advantage of turbine flowmeters is their relatively low cost when compared to new-technology flowmeters, such as ultrasonic and Coriolis. Despite the technological improvements by suppliers, having moving parts is still a disadvantage for turbine meters. Turbine meters also cause pressure drop. This is a necessary result of their technology, since placing a rotor in the flowstream causes some loss of pressure. However, some suppliers, such as Elster-Instromet, have addressed the issue of pressure loss with their bi-directional SM-RI-2 turbine flowmeter.

Traditional Technology Flowmeters Need Innovation

Traditional technology flowmeters still have an edge over new-technology flowmeters in terms of both revenues and units for flowmeters used for gas flow measurement. In 2010, new-technology flowmeters accounted for 39 percent of the total revenues for the gas flow measurement market, while traditional technology meters made up the remaining 61 percent. The primary reason for this is the size of the DP flowmeter market. This market, consisting of DP flow transmitters together with primary elements, accounts for 34 percent of the total worldwide gas flowmeter market. The DP flowmeter market is the largest of any gas flowmeter type on a worldwide basis.

In the long run, however, there is a shift in technologies from traditional technology to new-technology flowmeters in gas flow, just as there is in the broader flowmeter market. The primary reason is the higher accuracy and reliability of new-technology flowmeters, compared with their reduced need for maintenance. By 2015, new-technology flowmeters are projected to account for 46 percent of the total gas flowmeter market. However, the large installed base of DP and positive-displacement flowmeters especially will still make them a viable force, even four years from now.

One reason for the stronger growth rate forecast for new-technology flowmeters is that new-technology suppliers are currently investing more in research and development than are traditional meter suppliers. This means that there is a steady stream of new-technology flowmeters being introduced to the market. Suppliers of traditional flowmeters can help out their own cause by working in similar ways to bring out innovative products. Three companies that are doing this are Emerson Daniel, Elster-Instromet, and Cox Flow Measurement. If more suppliers of traditional flowmeters would devote more efforts to research and to bringing out new products, traditional meters could experience a faster growth rate.

One area that could use some innovation is primary elements, for example. Products like the Annubar® (Emerson Rosemount), the Accelabar® (Veris) and the V-Cone® (McCrometer) have made a major impact on the primary elements market. While primary elements are tied to DP flow technology, this technology remains the largest segment of the gas flow measurement market. New and innovative solutions in primary elements and for other traditional technology flowmeters can and will help keep these technologies in play for the foreseeable future.

Jesse Yoder, Ph.D., is president of Flow Research Inc. in Wakefield, Mass., a company he founded in 1998. He has 24 years of experience as an analyst and writer in process control. Dr. Yoder specializes in flowmeters and other field devices, including pressure and temperature products. He has written over 150 journal articles on instrumentation topics. Dr. Yoder can be reached at [email protected].

For more information on Flow Research’s research in the area of gas flow measurement, see www.gasflows.com.