Coriolis flowmeters are a proven and highly reliable technology in the flow measurement field. They are known for accuracy and consistency, but until recently, this technology was not considered for plants that could only accommodate two-wire devices due to a variety of reasons.

When considering replacing legacy two-wire flowmeters, many facilities lack the necessary cable rack space due to years of unmined cable to upgrade to standard four-wire Coriolis flowmeters. And, while plant managers may wistfully sigh and say they are simply using what is available, the reality is, these same plant managers will continue to deal with unexpected shutdowns, accuracy issues, unplanned maintenance or a need for workarounds.

Budgets are getting tighter, and many facilities need to find ways to increase efficiencies with less staff, especially as highly skilled workers are retiring at an increasing rate. So, what is the solution and how does it work?

Coriolis flowmeter reliability

What makes a Coriolis flowmeter so reliable in the first place? The obvious answer is that the meter has no moving parts that require servicing or replacement. But there’s more to the story.

Even though Italian scientist Giovanni Battista Riccioli first described the actual Coriolis effect in 1651, noting that a cannonball fired to the north will deflect to the west due to the rotation of the Earth, it wasn’t until 1835 when French mathematician and scientist Gaspard-Gustave de Coriolis first mathematically noted the Coriolis effect.

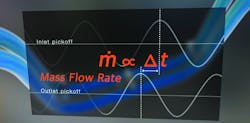

From Coriolis’ work in mathematical notation, it became possible to determine and clearly describe the Coriolis effect in more than just the Earth’s rotation and the meteorological effects created by that rotation. A flowmeter uses the same mathematically measurable principles by inducing a vibration in tubes that a fluid passes through. The vibration along the tubes provides a rotating frame of reference that indicates the Coriolis effect.

Specific methods may vary depending on the design of the meter, but the changes in the vibration observed represent the mass flow rate and density of the fluid, which can be mathematically calculated to give an accurate density and flow rate measurement.

Because of the simplicity and effectiveness of the design, a Coriolis flowmeter is highly accurate under a range of circumstances. It can accommodate significant turndown as well to meet efficient and safe plant operating requirements. Particularly in the hydrocarbon and chemical industries, a turndown ratio of 50:1 is a desirable option to meet flow needs and process parameters.

Figure 2. A visual and mathematical representation of mass flow rate

The desire for two-wire technology

When many of today’s chemical plants, refineries and power generation stations were built, Coriolis flowmeters were not available in a two-wire configuration. However, with advances in technology, this is now a viable option. For many plants that have historically used two-wire technology and are now in need of retrofitting, this is good news.

In the past, many plants had to use whatever was available in the market, which included differential pressure (DP), positive displacement (PD) and turbine meters. Each of these meters presents challenges with reliability and accuracy; not the least of those problems is that they all have moving parts that can wear out, need maintenance and lead to unscheduled plant shutdowns.

Historically, turbine meters have been relatively inexpensive, but when adding up regular scheduled and unscheduled maintenance, part replacement and revenue lost through scheduled — and unscheduled — downtime over the life of the meter, they become far less of a bargain.

Flowmeter reliability is key

In industries where volatility is an issue and an unnoticed change in the material flowing through the pipes can spell disaster — ranging from lost material and revenue, to plant shutdowns, to the possibility of causing an unsafe plant environment — reliability of the equipment and tools is a critical must.

Not only do meters need to operate within set parameters, but also provide the ability to add in the right diagnostic tools to help improve overall measurement data. Having the right diagnostics is like having an engineer built right into the meter, checking all elements of the flow and alerting users to problems well before they become critical.

Meter diagnostics have been an integral part of the standard Coriolis flowmeter and are now a part of a two-wire Coriolis flowmeter, giving the meter an advantage over existing technologies. These added tools make the Coriolis flowmeter more accurate and reliable, which saves costs over the life of the flowmeter.

Capital expense versus ROI

In any project, from an upgrade or retrofit to engineering the configuration and technology of a completely new plant, cost is a primary factor in every step of the process.

Consider a retrofit as an example. An existing plant might have cabling in the overhead racks that goes back 40 or 50 years to when the plant first began operation. Over the years, more cables may have been added to replace old ones, but the old cables were left in place because the plant could not afford to stand idle during any removal work. Even today, removing that much cabling would require significant time and manpower — an expense no plant wants to put on its books.

However, a simpler and more cost-effective solution is to swap out existing two-wire meters and reuse the existing cable by installing a Coriolis two-wire flowmeter without adding wiring expenses or needing to run piping for flow conditioning.

Sign of the times

Having the best possible tools for the job increases safety and efficiency and improves the bottom line. It can also smooth the transition — as experienced engineers retire and are replaced by millennials — ensuring that year-over-year goals are met.

Many of those retiring engineers and technicians take with them decades of experience on how to work with the infrastructure, how to read a meter and how to troubleshoot. They know the shortcuts, the workarounds and temporary fixes to keep a process running. But that is hard-won knowledge that cannot just be transferred in a few days of training. This is where an investment in retrofitting gains yet another attractive checkmark in the pro column.

New meters with advanced diagnostic tools require fewer initial skills and training to be used by a new hire. Also, new meters let the user know if problems arise and can suggest the next course of action. With the right equipment and tools, personnel will be better positioned for success and have a greater ability to reduce risks to the processes and the plant — a benefit for management at all levels.

Anthony Gentile is a marketing product manager with Emerson Automation Solutions, Micro Motion. He has 15 years of experience in the area of Coriolis flow measurement and holds a bachelor’s degree in chemical engineering and petroleum refining from Colorado School of Mines, as well as an MBA from Regis University.