For decades in the food and beverage industry, instrument data was constrained to single analog process variables communicated via individual 4-20mA current loops. But modern instrumentation advances, particularly digital communications, now provide a wealth of additional diagnostic and other information, providing operational insights which are not easily obtained using conventional 4-20mA measurements alone. However, a lack of awareness of digital capabilities that are already present among existing instrumentation has led to a delay in adoption in the food and beverage sector.

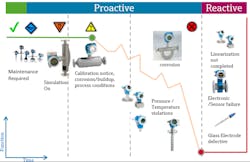

In today’s data-centric landscape, smart instrumentation provides a wealth of diagnostic and other information, empowering plant personnel to get far more from their instruments than a single 4-20mA primary process variable. This extended data, transmitted from instruments to host systems via digital communication protocols, helps plant personnel improve efficiency and avoid unplanned shutdowns by giving them the data they need to implement proactive maintenance and predictive monitoring (Figure 1).

Engineers, managers and operators in the food and beverage industry are observing their peers in other industries, who are often farther down the path of digital transformation, and — encouraged by the results — are also beginning to embrace this digitalization trend.

Conventional instrumentation challenges

Many factors impact and even interfere with the accuracy of a conventional instrument’s process variable analog output. Operators interpreting such a signal received by a programmable logic controller, distributed control system, asset management system or another host system simply have no other information regarding its accuracy. Each analog loop scales a single process value as electrical current, but is unable to transmit secondary variables, such as temperature on a pressure instrument. Additionally, communication is unidirectional only, so there is no way to send commands from a host to the instrument.

Traditional analog instrumentation also lacks diagnostic information, making it nearly impossible to foresee or troubleshoot instrument failure. Malfunctions cause unplanned downtime and costly instrumentation repairs in the best cases, or catastrophic equipment damage and safety hazards in the worst. Bound by analog electronics, traditional instruments must be hardwired to a host system, sometimes limiting placement in hard-to-reach areas of a facility.

Digital pathways for enhanced connectivity

HART over 4-20mA

For retrofitted and new applications where hardwiring transmitters back to a host system is existing or convenient, instruments can use the bi-directional digital HART communication protocol. Data is superimposed on a 4-20mA analog current loop, providing two-way communications between an instrument and a host system. The exchanged data includes primary process values, one or more secondary process values, diagnostics, calibration, maintenance and other information. This wealth of data makes configuration easy and improves operational process insights, compared to traditional analog-only instrumentation.

Because HART-enabled instruments can transmit multiple process values to a controller via a single loop, users gain flexibility to continue using existing analog loops for real-time control, while taking advantage of additional process and diagnostic data provided to the host system for making data-driven decisions within a facility (Figure 2).

An estimated 80% of instrumentation used for real-time control and monitoring in the food and beverage industry already supports HART, but many processors are not using it, often because they are unaware of this existing capability.

Transmitting this data is also possible via many Ethernet-based protocols. These provide several of the same benefits as HART, but typically operate at much higher speeds, enabling the inclusion of more information, along with faster response times.

IO-Link

IO-Link possesses a unique set of advantages — particularly for applications in the food and beverage industry — combining simple configuration, a standardized protocol, fast data transmission speeds and cost efficiency. Recognized as an international standard IEC 61131-9, IO-Link is a bidirectional digital communications protocol that provides measurement and other devices with basic functionality, most notably instrument diagnostic information.

Similar to a remote input/output (I/O) hub, an IO-Link “master” device is used to connect multiple instruments to a host system via an industrial Ethernet protocol, such as EtherNet/IP, PROFINET or Modbus-TCP/IP. The master serves as a gateway, transmitting diagnostic data, secondary process values and host system commands among all connected devices (Figure 3).

Integrating IO-Link-capable instruments, using M12 washdown-grade connectors and unshielded cables up to 20 meters in length, is especially popular among machine builders and skid suppliers in the food and beverage industry. This is because basic instruments with support for IO-Link fulfill most operational requirements, while the diagnostics of IO-Link can drastically improve troubleshooting efforts when issues arise. The installation requirements of fieldbuses add complexity and costs, but IO-Link instruments, by contrast, are about as close to “plug-and-play” as any come.

Additionally, the majority of IO-Link instruments can be optionally operated in 4–20mA analog mode with simple configuration and wiring changes, enabling flexible installation and integration. When ready, facilities can switch the devices to digital mode to harness the power of remote configuration, increased instrument diagnostic data and multiple process variables transmitted from a single instrument.

Compared to instrumentation with direct Ethernet connectivity, IO-Link devices are not directly accessible from an upper-level system, such as an asset management system. Instead, users must tunnel through the IO-Link master to reach them. However, faster data polling speeds make this quicker than connecting to instruments via HART. But one of the greatest strengths of IO-Link systems is the simplicity of instrument configuration and ease of device replacement, reducing the level of training required to maintain and service plant instrumentation.

Ethernet-APL

The Ethernet Advanced Physical Layer (Ethernet-APL) is a more recent development, providing the ability to transmit digital data via industrial Ethernet protocols using a single two-wired shielded cable per instrument, while also providing power for 4-wire instruments. With the same cable requirements as HART — though markedly different gateway and termination specifications — Ethernet-APL can simplify retrofits by eliminating the need to pull new wires to instruments (Figure 4).

Ethernet-APL is protocol agnostic, and it supports industrial communication protocols such as PROFINET, EtherNet/IP, Modbus TCP, HART-IP, OPC UA and other higher-level network protocols (Figure 5).

Ethernet-APL provides high-speed data transmission at a 10Mbit/s data rate, making it possible to send and receive more data than is possible with older digital methods. It provides a robust basis for continuous diagnostics, monitoring, industrial internet of things connectivity and remote instrumentation verification.

Because communication is handled via standard Ethernet protocols, instrument data routing among process control systems and asset management tools is highly efficient as most control environments already support these protocols.

Results

Food and beverage automation systems regularly use primary process data to monitor and control operations, but plant personnel often discard status and diagnostic data. By dismissing this data, facilities miss out on opportunities to optimize, simplify and safeguard their operations.

A corn wet-milling facility was experiencing issues with one of its processes, and it began to suspect a flowmeter was providing inaccurate values. However, an online Heartbeat verification of the installed Endress+Hauser Promag H300 electromagnetic flowmeter using instrument diagnostic data proved the flowmeter was not the source of the issue.

The online protocol, leveraging diagnostic data, saved two technicians six hours of labor, along with plant downtime, by alleviating the need to remove, replace and bench test the flowmeter in questions. Within a matter of minutes, the processor determined the meter was working within specifications, so it moved on to troubleshooting other components. It turned out there was a problem with an upstream valve, causing unexpected flow rates.

Online diagnostics increase reliability and uptime

Today’s smart instruments provide a plethora of diagnostic data, helping processors maintain their systems with much greater reliability. The trick is often simply realizing the data is available, and then adjusting operational workflows to use it effectively.

Instrument diagnostics and other functions make it easier to detect problems, and with quicker troubleshooting and servicing when issues arise. Sustaining a competitive edge in the food and beverage industry requires topnotch production efficiency and precise monitoring of variables like stock, hygiene, safety and inventory conditions are crucial to minimize material waste and adhere to strict standards.

Digital protocols in general, and IO-Link in particular, can help food and beverage processors, who experience challenges with the constant threat of product loss and the difficulties of rigorous manual management. These capabilities help expand visibility and generate holistic insights, empowering plant personnel to optimize operational efficiency, maintain product quality and maximize profitability.

Ola Wesstrom is the senior industry manager of Food & Beverage for Endress+Hauser USA. He is responsible for the development and implementation of best practice measurement solutions, supporting customers throughout the industry segment. Ola has a Bachelor of Science degree in instrumentation and automation from National Pulp & Paper College in Sweden. Since joining Endress+Hauser in 1992, he has held various positions, focusing on Food & Beverage since 2001.

Endress+Hauser