Much of the world’s oil and gas is produced offshore and then transported over the ocean to marine storage terminals before refining and distribution. The marine terminals that receive oil and gas products are complex hives of activity as bulk fuels or refined petrochemical products are loaded or unloaded from ships and then stored in large tank complexes prior to pipeline or other modes of delivery to the eventual end users.

Safety is always the primary concern at marine terminals because these bulk fuels and refined petrochemicals can be highly combustible and flammable, as well as toxic. Any spills that occur have serious potential safety and environmental effects. Transferring oil and gas products from ship to shore or vice versa requires highly specialized equipment and trained operators. When these fluids are moved from tanker ships into the terminal and to storage tank areas, two of the major challenges are always loading/unloading spills and tank overfills.

During unloading/transfer, there is a high potential for explosions and fires that can quickly spread to the rest of the terminal. Such accidents can be catastrophic if the equipment is not used properly and if precautions are not taken to ensure safe, efficient operations. Moreover, cargo ships and terminal facilities have been tasked by governments and other regulatory bodies around the world to significantly reduce pollution.

The challenges

Terminal loading arms connect shore installations to vessels delivering or transporting petrochemical products such as crude oil, diesel, petrol bitumen products and many different types of specialized chemicals. Loading arms are highly engineered, specialized pieces of equipment that, in marine environments, must adjust themselves to the constant motion of tankers responding to windy weather and the ocean tides.

The terminal loading arms have flexible joints that connect to shore installations and the various sizes of vessel so the fluid or gas product can either be pumped in or out of these vessels. They have to cross over relatively long distances, and they have counter weights installed to balance the weight of the product being pumped.

At rest when not in use, the arms often catch a lot of high winds and become easily unbalanced if the point of gravity is not at the bottom where the counter weight is located. In the at-rest position, it is critical that these arms are completely empty when retracted into their folded rest position. In order for the arms to fold properly, any remaining residual fluid leftover in the arms after finishing the loading or unloading process must then be returned to a slob tank.

To ensure the arm is completely empty after loading/unloading requires the operators to keep the pump running a little longer to transport any remaining fluid into the slob tank. Another potential spill process hazard exists if the connection from the arm to the slob tank is not entirely open. When the arm is partially closed, this position prevents the arm from fully draining, so product stays behind in the loading arm.

If the arm is not fully drained, accidents have happened under stormy high wind conditions when the loading arms have tipped over because of the weight of the product left in the arm. These accidents have potentially hazardous consequences because of the highly combustible nature of petrochemical products and could endanger workers, damage vessels or affect other onshore terminal equipment.

Best practice solutions

When a marine terminal’s operating team decided to prevent this type of loading arm accident, they contacted the applications group at Fluid Components International (FCI) to discuss ways to improve operational safety. The FCI applications staff listened to the terminal team’s concerns and suggested that its thermal flow sensing technology and flow switch expertise could be of value in resolving the issues.

Beyond solving the primary problem, the dual-alarm FLT Switch’s Alarm 2 is also now set to detect when fluid is flowing through the loading arm in both directions: The switch indicates when fluid is flowing for either loading or unloading ships, making maximal use of the switch to ensure safe operation of the loading arm under all operating conditions.

In a different marine terminal location, the switch is helping terminal supervisors verify that its workers have opened the correct valve and/or turned on the correct pump to send the correct fluid to the intended tank or vessel during unloading/loading operations. Sending the wrong fluid to the wrong location can cause a number of problems including overfills and spills, as well as cross-contaminating products.

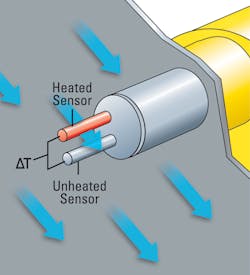

Flow switch technology

The switch’s electronic control circuit converts the RTD temperature difference into a conditioned DC voltage signal. These signals are used to drive adjustable set point alarm circuits and outputs. Depending on the switch configuration, alarms are field-configurable for flow, temperature, high or low, hysteresis, time delay and more.

The fact that this flow switch’s sensor is free of any moving parts and is robust enough for heavy-duty applications and harsh physical environments such as the outdoor location where the loading arms are in operation was appreciated by the terminal operations team. The flow sensor is designed with all-welded construction using 316L stainless steel or other materials such as Hastelloy C, Monel or titanium where corrosion is a concern.

The switch’s sensing and switching capability is achieved by combining a precision, all-welded sensing element with an advanced, user-friendly control circuit. Two standard sensing element configurations are available: The “S” element was chosen by the terminal operations team and is designed for use in standard heavy industrial applications and in applications with high velocity liquid set point requirements. The switch’s “F” element configuration is designed for fast-response gas applications.

The switch’s accuracy of liquid flow measurement is as precise as ±2% of the set point velocity over a ±50°F temperature range; repeatability is ±0.5% reading. Both sensing elements can be supplied in either standard (-40°F to 350°F) or medium (-100°F to 500°F) temperature configurations. The “S” element is also available in an optional high temperature (-100°F to 850°F) configuration.

The standard electronics package provided with this switch is integrally mounted in an IP67-rated enclosure, either epoxy-coated aluminum or, for close-to-shore installations, in an all stainless steel enclosure, which was chosen by the terminal’s operations team. The remote mounting of the electronics up to 150 meters away is available to meet safety requirements.

The terminal’s operations team found the switch was easy to set by utilizing the available analog output signals. They could easily view the status of the switch via its built-in display and do routine checks without removing the switch from the loading arm, switching to simulation mode and reading voltage settings is all they need to do.

This switch comes with a choice of process connections: NPT, BSP or ANSI and DIN flanged, or a retractable version is available for hot tap requirements. While the switch relies on an insertion configuration type of sensor, its outer diameter is a maximum of only 22 millimeters and the resulting pressure drop is less than 1 milliBar, so there is no loss of pumping energy or risk of blockages because of the sensor.

The operations team also appreciated the certified SIL-2 compliance of the FLT Switch. It is also available with multiple hazardous area approvals, including FM, CSA, IEcEx, ATEX and GOST. The SIL-2 compliance and the multiple safety approvals supported the terminal operation team’s overall regulatory compliance requirements.

Conclusion

For two-plus years, the FLT Switch has been successfully operating without incident in the terminal operator’s loading arms. Since then, the terminal operator has installed additional switches in its process due to the performance of these switches in the loading arms application.

Richard Koeken is the regional sales manager for Europe/CIS/Africa at Fluid Components International, a manufacturer of flow and level measuring instrumentation utilizing thermal dispersion technology. Koeken has been with FCI for nearly five years. He has over 10 years of experience helping customers in several different market sectors to find a solution in meeting their flow measurement challenges. He can be reached at [email protected].

Richard Thomassen is the product manager at ODS Metering Systems in the Netherlands. He has over 20 years of experience specializing in flowmeter, process analyzers and sampling systems for the oil and gas and petro chemical industries. Thomassen holds a Bachelor of Science in chemical engineering from Rotterdam University of Applied Sciences. He can be reached at [email protected].