Oilfield reservoir souring — increased concentrations of hydrogen sulphide (H2S) in oil production — is a significant problem for operators. Because hydrogen sulfide is toxic and highly corrosive, sour crude is more expensive to refine than sweet crude oil, which typically contains less than 0.5% sulfur.

While sulfide is often found to occur naturally in oil, the process of pumping seawater into reservoirs to maintain pressure during secondary recovery can introduce sulfate-reducing bacteria into what would otherwise be a sweet crude oil environment. Microbiological oilfield reservoir souring is a process in which the introduction of seawater provides the additional sulfate and microbiology needed for increased concentrations of hydrogen sulphide when downhole conditions are optimal for microbial growth.

It can take several years of secondary recovery operations and resulting microbial activity before increased souring is detected in produced fluids, thus operators need to accurately assess whether souring is likely to take place in their fields and identify the risk early enough to ensure it can be treated cost-effectively. Treatments include the use of injection chemistries, such as nitrates and biocides, or through end-of-pipe scavenger solutions.

Typical approaches to souring remediation and souring control are categorized by the following two distinct types of chemical treatment:

- Competitive-exclusion treatments, i.e., encouraging nonsouring bacteria

- Biocide injection, i.e., attempting to kill all bacteria

Competitive-exclusion treatments

Calcium nitrate is classified as a competitive-exclusion treatment for reservoir souring, as this promotes the growth of nitrate-reducing bacteria, which can then outcompete the problematic sulfate-reducing bacteria in the reservoir. Both sulfate-reducing bacteria and nitrate-reducing bacteria are present in seawater and are introduced together during secondary recovery.

As the reduction of nitrate ions to nitrogen is a more "energetically-favorable" metabolic process, nitrate injection results in the proliferation of nitrate-reducing bacteria and the utilization of nitrate rather than sulfate as an electron acceptor. Therefore, souring remediation and souring control can be observed in wells that are receiving the correct dose concentration of calcium nitrate. However, if insufficient calcium nitrate is injected into the oilfield, this can result in the growth of sulfate-reducing bacteria and the production of sour fluids.

Calcium nitrate injection can be a suitable souring remediation and souring control strategy for field operations. However, the chemical demand of an injector-producer pair is dependent on how favorable the downhole conditions may be for microbiological growth. For example, in wells that have a large volume of rock and can support microbiological growth, it may be found that the calcium nitrate demand for complete souring remediation is too great for the well to operate economically or that such large quantities of chemical cannot be shipped and stored on the platform.

That said, if a well has a lower microbiological activity, thus a lower souring propensity, the concentrations of calcium nitrate required for souring control become economically and logistically viable. Such treatment can ensure that produced fluids from the field require less topside processing and that any produced crude oil is within export tolerance limits for sulfide concentrations.

Biocide injection

In the latter case, biocides are used for good "housekeeping" practice to keep topsides water injection systems clean and to attempt a delay in the establishment of biogenic souring. The two most common broad-spectrum biocides used in field operations are glutaraldehyde and tetrakis (hydroxymethyl) phosphonium sulfate (THPS)-based products. The biocidal activity of glutaraldehyde is due to the ability of the molecule to alter DNA, RNA and protein synthesis within the microbial cells. However, THPS has an alternate mode of action by increasing the permeability of cell membranes, resulting in the loss of essential cellular material.

Microbiological oilfield souring research

Until recently, laboratory-based investigations into whether an oilfield would sour involved the use of simple sand, oil and seawater bottle tests, or upflow sand packs subjected to atmospheric pressure. However, these tests could not be used to draw accurate comparisons with actual field conditions and biological activity, primarily because they were unable to replicate the pressures or temperatures found downhole.

With at least 45 pressurized bioreactor columns, ranging from 25 centimeters to 4 meters in length, in daily operation at its research facility, Rawwater has been subculturing oilfield bacteria strains for more than 30 years. By 2018, the company had accrued the equivalent of 400 years’ worth of pressurized oilfield souring data — a growing data set containing information relevant to reservoirs worldwide. Testing conditions cover a spectrum of oil types and range from atmospheric pressure to 12,000 psig, with temperatures up to the boiling point of water. Souring studies have lasted from a matter of weeks to a number of years to monitor the rate of souring and have been operated using crude oil and seawater samples from major oilfields globally.

Predictive data tool

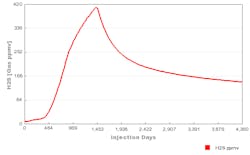

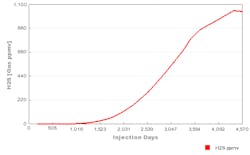

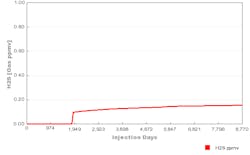

Once a base profile for souring is established, a real-time sensitivities processor is used to examine the effects of changes across multiple parameters, for example, modifying inputs such as injection temperature, injection sulfate concentration and time to breakthrough of injected water.

Conclusion

Due to the significant health, safety and economic implications related to downhole microbiological souring, souring forecasting is essential. Souring remediation regimes should be implemented to maximize treatment efficacy and optimize the economic viability of field operations.