Improving technologies and methods to increase the recovery of oil from existing reservoirs is a global challenge. In the U.S., oil production at reservoirs can include three phases: primary, secondary and tertiary (or enhanced) recovery. The U.S. Department of Energy (DOE) estimates that primary recovery methods — which rely on the natural pressure of the reservoir or gravity to drive oil into the wellbore, combined with pumps to bring the oil to the surface — typically tap only 10 percent of a reservoir’s oil. Furthermore, secondary efforts to extend a field’s productive life — generally by injecting water or gas to displace oil and drive it to a production wellbore — still only push recovery totals to between 20 and 40 percent of the original oil in place. Clearly, much untapped oil and gas remains in existing wells.

Enhanced oil recovery

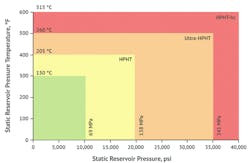

As a result, oil and gas exploration and production companies are increasingly operating in high-pressure, high-temperature (HPHT) downhole conditions using enhanced oil recovery (EOR) techniques to extract as much of the remaining 60 to 80 percent out of the reservoir as economically feasible. These newer production methods typically utilize gas, thermal or chemical injection to extend the productive life of a play.

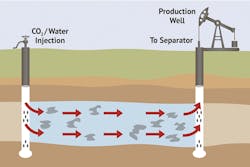

Gas injection uses natural gas, nitrogen or carbon dioxide that expands in a reservoir to push additional oil to a production wellbore — or other gases that dissolve in the oil to lower its viscosity and improve its flow rate. According to DOE, gas injection now accounts for nearly 60 percent of EOR production in the U.S.

Thermal recovery introduces heat, typically steam, to lower the viscosity of oil and improve its ability to flow through the reservoir. Thermal techniques are employed in more than 40 percent of U.S. EOR production.

Chemical injection involves the use of long-chained molecules called polymers to increase the effectiveness of waterfloods or the use of detergent-like surfactants to help lower the surface tension that can prevent oil from moving through a reservoir. Chemical techniques figure in about 1 percent of EOR production in the U.S.

Despite the effectiveness of these methods, they place significant additional strains on the mechanical seals, pump seals, O-rings, gaskets, T-seals and packings that are the workhorses of downhole oil and gas recovery applications. Exposure to high temperatures can cause these seals to lose their elasticity, making them hard, brittle and susceptible to outgassing. Contact with harsh chemicals and solvents can cause some elastomeric seals to swell, potentially leading to their rupture and the contamination of both the process and outside environments.

High-pressure, high-temperature enhanced oil recovery techniques require ultra-durable equipment components.

Elastomer challenges at HPHT

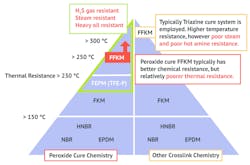

Many kinds of fluoroelastomers exist, each with its own features. Of these, peroxide-curable hydrogenated nitrile butadiene rubber (HNBR), nitrile rubber (NBR) and ethylene propylene diene monomer rubber (EPDM) have a thermal resistance of greater than 150°C. Peroxide-curable tetrafluoroethylene propylene (FEPM/TFE-P) has a thermal resistance of greater than 230°C.

Triazine-curable perfluoroelastomers (FFKMs) have higher temperature resistance of greater than 300°C; however, they have poor steam and hot amine resistance. Peroxide-curable FFKMs typically have better chemical resistance but relatively poorer thermal resistance. Therefore, specialized FFKM solutions have been developed.

New ultra-polymers

Components made from specialized peroxide-curable FFKMs can meet the challenges of operating in these harsh environments, exceeding the performance characteristics of the fluoroelastomer (FKM) and HNBR families of elastomers now commonly used in many oil and gas industry applications.

Specialized peroxide-curable FFKMs provide superior resistance to the high temperatures, pressures and increasingly aggressive chemicals employed in oil and gas recovery and, therefore, are better resins for fabricating O-rings, gaskets and other oil field seals and packings. Components formulated with these peroxide-cured FFKMs resist wear and last longer in critical applications, resulting in reduced downtime, improved productivity and decreased maintenance costs.

The chemical structure of these resins is derived from tetrafluoroethylene and perfluoroalkyl vinyl ether, which offers the highest resistance to chemicals, oils and solvents — and provides excellent compression set resistance, mechanical strength, electrical insulation and ease of processing. They also can be compounded and molded to be highly resistant to rapid gas decompression (RGD).

Specialized FFKM formulations improve performance in high-pressure, high-temperature environments. Many kinds of fluoroelastomers exist, each with different features.

Thermal capacities of specialized peroxide-curable FFKMs depend on the grade selected for the application. Some FFKMs can impart a continuous service temperature at 230°C with peak excursion exposure to 250°C. Others can impart a continuous service temperature at 250°C with peak excursion exposure to 270°C, while even newer grades can surpass 300°C.

These materials can also be used to fabricate parts for demanding applications in the harsh environments found in the chemical processing, industrial equipment, food handling, semiconductor manufacturing, pharmaceutical, heavy-duty diesel and automotive industries.

Allowance for customized parts

When specialized peroxide-curable FFKMs are supplied to customers as a raw product rather than as a finished part, manufacturers can customize the finished part for their clients’ specific needs. However, this requires that these resins be optimally formulated, molded and cured to take full advantage of their physical properties.

The optimal formulation depends on the intended use in each case. Press cure conditions (temperature and time) must be decided in consideration of a variety of factors, such as the size of parts, required properties and scorch safety.

To achieve the best physical properties, these resins also require a post cure. The recommended standard condition is 250°C for four hours or more in air (or inert atmosphere). Cure times must also be optimized based on the size of the part.

Return on investment

As specialty elastomers designed to perform without failure in the most aggressive operating environments, specialized peroxide-curable FFKMs are priced commensurately. However, because these parts are mission-critical components of oil and gas exploration and production operations, elastomeric seals that underperform and leak or rupture can be a safety, environmental and liability risk that results in incalculable costs to human life, aquatic and atmospheric ecosystems — and a company’s reputation.

Reference

- Enhanced Oil Recovery, U.S. Department of Energy. https://energy.gov/fe/science-innovation/oil-gas-research/enhanced-oil-recovery

Masahide Yodogawa is group leader of Fluoropolymer Processing Group, R&D Division with AGC (Asahi Glass Company Ltd., Tokyo, Japan). He joined AGC in 1999 and has spent more than 18 years conducting material technology development of fluoropolymers and fluoroelastomers.