Safety. Cost-effectiveness. Optimal valve selection. Inventory reduction. Plant operators are familiar with these terms that require time, effort and a lot of money to address. Correct? Well, not necessarily so.

Many plant owners and operators spend a tremendous amount of money on Front End Engineering and Design (FEED) and perhaps long negotiations with Engineering, Procurement and Construction services (EPCs), but the aim is common: to optimize the process of selecting the correct equipment for the safe, reliable operation of the plant. Optimizing the process can be achieved with a relatively simple, but logical, approach to a company’s Total Cost of Ownership (TCO) program.

Owners of chemical and petrochemical plants throughout the world continually seek effective approaches for achieving measurable improvements in their TCOs. To address this customer need, a new collaborative project with major chemical and petrochemical companies is designed to develop, promote and implement standardization programs and processes. These initiatives will focus on the goal of increasing efficiency and reducing TCO related to the procurement, installation and maintenance of valves and controls equipment, and inventory control processes across multiple plant sites.

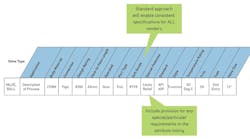

Figure 1. Typical example of minimum attributes required to specify a ball valve

Some companies embrace and benefit from standardization programs. The project allows suppliers to support them with their standardization initiatives.

Customers can potentially save millions of dollars annually by standardizing the models of valves and control equipment that they use enterprise-wide. This increases reliability and efficiency and delivers proven results. The standardization process described begins with an evaluation. Once the evaluation is completed, a team then works in collaboration with the customer to develop and implement a customized standardization plan across their facilities over a period of several years.

Some TCO benefits that customers can expect from this standardization project include, but are not limited to:

- Cost savings by commonly used processes across the enterprise to define, specify and order technical equipment

- Availability of products on short notice to allow quick response and delivery to solve problems

- Technology-driven product standardization with reliable, high-quality products that significantly reduces plant downtimes, unexpected outages and operational issues

- Technical support and consultancy provided by dedicated representatives to enhance partnerships and identify new areas for improvements for customers

- Long-term commitment and a solutions-oriented team approach to help customers with their toughest challenges and deliver the best value and TCO

- Standardization on best possible product selection across multiple facilities. These products must be suitable to the application to increase reliability and lifetime. (Note that specifying, purchasing and installing valves and other technical products that are the best-in-class may not be the least expensive approach, but it is the best approach for safety and reliability.)

Standardization for success: How it works

The approach to achieving an effective standardization process and program includes three primary components:

- Availability of accurate specifications and datasheets for commonly used valves and other technical components is of prime importance. In the business process, the end user provides the specification for products. When more detailed information and accurate data is provided by the end user, the supplier can address the customer’s specific need more effectively. Major design criteria must be accurate so that “assumption” work – which can cause significant problems such as increased downtime and/or retrospective refit work – can be significantly reduced with the goal of eventually being completely eliminated. Having accurate and complete specifications is critical to unlocking a facility’s potential to reduce costs, improve efficiency and ensure safety by standardizing on valves and controls equipment.

The potential of having an incorrect or inaccurate order specification can have a negative impact on operational safety. Specifications that allow interpretation of key design elements can cause catastrophic accidents like failures of valves critical for safety or stable production. The goal is to reduce downtime and improve reliability and efficiency.

- Identifying and adopting best practices related to specifications and inventory management and suppliers using a standardized approach are key parts of the overall process. The standardization approach includes:

- Standardizing specifications for pipe class and valve class development (i.e., customers and suppliers must look at the bigger picture). Valve manufacturers must work closely with customers to align their processes for maximum, mutual benefit. Original equipment manufacturers (OEMs) need to identify a valve’s prime function before proceeding to identify and standardize on the use of the pipe class and valve class by identifying the most common fluids; using a common pipe class system; selecting major vendors; developing basic rules – technical delivery conditions; defining valve specification forms and requirements across a variety of fluids; developing common valve specifications; starting with top 10 valve types; and expanding to all valve types.

- Adopting an inventory management approach. How does this work best?

- Standardize – Analyze previous usage with standardized item numbers to determine inventory and know the current state of inventory.

- Optimize – Use findings to develop a centralized material management system and supply chain.

- Localize – Assess and ensure the availability of correctly specified equipment and parts for distribution to the local site. Make parts available to reduce delivery time and increase access in time (time, cost and availability).

- Working with suppliers who adopt and maintain a consistent, standardized approach (i.e., all competing suppliers use the same product and equipment description, which leads to a simpler procurement process) leads to better collaboration and a streamlined work flow.

- Ensuring consistent execution by all parties and early supplier involvement leads to program success. Having the highest level of management commitment within the end user’s organization is extremely important. However, to be truly effective, developing a trusting relationship between end users and key suppliers facilitates early supplier involvement and allows suppliers visibility within that end user’s organization. the common goal between an end user and a supplier is to work within their core competencies to provide a powerful formula for joint success.Critical steps to ensure consistent execution and early supplier involvement are: Define project concepts while leveraging the OEMs’ expertise and knowledge; provide technical support and advice during specifications planning; reduce time and costs by better interfacing with the EPC provider; enable the OEM to dedicate manufacturing capacity for project-specific activities; and identify engineering cut-off points and capture changes to engineering requirements before progressing to the assembly stage, mitigating cost and scheduling implications.

Impact on the bottom line

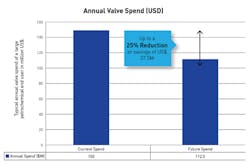

By implementing an effective standardization program, customers can expect to reduce their TCOs by up to 25 percent, which translates to potential savings of millions of dollars annually.

Suppliers of valves, controls and other plant automation equipment and solutions must continually address and adapt to add value to the customers they serve. The relationship between valve manufacturers and end users can often change dramatically because of new technologies, innovative processes, rapid execution of capital investments and other unplanned factors that affect operations. The best way to develop and enhance the relationship between a supplier and a customer is for the supplier to care enough about that customer’s business as if it were its own.

Christof Lindner is director of Pentair Valves & Controls global accounts for the chemical and petrochemical industry. He may be reached at [email protected]. For more information, click here.