The geared products global market is expected to stagnate going into 2016. Like other downstream process industry sectors, a volatile global economy and geopolitical uncertainties are hurting the gearboxes market following growth in 2014. The market had seen a strong recovery in 2010 and 2011 followed by a contraction in 2012 and slight recovery in 2013. The market grew slightly going into 2014 with an estimated worth of more than $12 billion.

Data analytics company IHS, Inc. predicts the geared products market will gradually grow from the middle of the forecast period with a revenue compounded annual growth rate (CAGR) of 1.6 percent from 2014 to 2019 to reach $13.0 billion in 2019.

Asia Pacific was still the largest regional market for geared products in 2014. The region held 46 percent of global revenues with an estimated value exceeding $5.5 billion. The Europe, the Middle East and Africa (EMEA) region was the second-largest regional market in 2014 with a value of over $43 billion, representing 36 percent of global revenues.

Performance of gearboxes and geared motors

The market for gearboxes continued to be larger than 2014, accounting for an estimated 60.3 percent of market revenues. However, IHS forecasts that the market gearboxes will grow much slower than the market for geared motors through 2019, with contraction occurring up to 2016. Overall, the market is predicted to generate a revenue CAGR of 0.9 percent from 2014 to 2019 primarily because of the underperformance of its main downstream process industry sectors, especially mining and cement as well as metal processing.

The market for geared motors is forecast to see a 2.8 percent revenue CAGR from 2014 to 2019. This is caused in part because the share of geared motors in discrete industry sectors is higher than gearboxes’, and the discrete sector for geared products is forecast to grow faster than those of the process sector from 2014 to 2019. The geared motor market is projected to reach nearly $5.5 billion in 2019, accounting for approximately 42 percent of total geared products. This is up from 39.7 percent in 2014.

Downstream industry performance

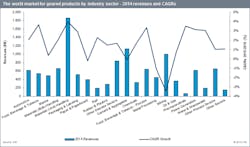

The performance of the geared product market is largely dependent on the underlying growth in the industries that use them, which include many machinery and process sectors. The materials (unit) handling sector is the largest sector for geared products. It accounted for 15.5 percent of market revenues in 2014 with an estimated value of nearly $19 billion and the highest revenue CAGR from 2014 to 2019 at 4 percent.

The food and beverage sector (including machinery and process) is the next largest sector, and it is projected to also grow at the second-fastest CAGR of the downstream industries at 3.5 percent from 2014 to 2019. Mining, one of the major downstream sectors, is forecast to perform the worst across all industry sectors with a revenue CAGR of -3.4 percent, followed by metal processing.

Looking at the market landscape, European suppliers continued to lead the total market for geared products in 2014, with eight out of the top 10 companies making up an estimated 45 percent of total global revenues in 2014. SEW Eurodrive remained the market leader in geared products, primarily because of its dominance in geared motors. Siemens was the market share leader for gearboxes and held the second highest total geared product market share.