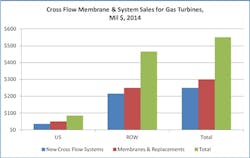

The market for cross-flow membrane systems, repair parts, replacement membranes, chemicals, and related instrumentation for use in gas turbine and combined cycle power plants will exceed $550 million this year, according to McIlvaine Company.

Gas turbine systems utilize cross-flow systems, including reverse osmosis, ultrafiltration, and microfiltration, in a number of processes.

Applications include:

1. Intake water

2. Boiler feedwater

3. Cooling tower recycle

4. Fogging nozzle dematerialized water

5. Wastewater from the cooling tower and balance of plant.

The report says there is an increasing use of treated municipal wastewater in new plants. This frequently requires the use of membrane systems to make the water suitable for plant uses.

READ ALSO: East Asia to Lead Cross-Flow Membrane Market in 2014

The boiler feedwater system includes a series of filtration steps and it is common to have microfiltration or ultrafiltration for prefiltration before entering the reverse-osmosis (RO) system.

Cooling water, as it recycles, builds up concentrations of solids that must be reduced. Microfiltration is one option to accomplish the needed separation. Fogging nozzles improve the plant output by evaporating water in the inlet gas stream. This water must be purified to prevent maintenance problems.

The practice of eliminating all wastewater in a zero liquid discharge system is increasing, while cross-flow membranes are being used to provide water for reuse, the report says.

Since membranes must be replaced every few years, the market for replacement parts is growing; as is the market for repair parts for pumps, valves, and instrumentation and treatment chemicals to prevent membrane scaling.

For more membrane filtration-related news and products, go here.