Just as there are many applications for pressure measurement, there are also many different instruments used for pressure measurement. These include pressure gauges, pressure sensors, pressure transducers, and pressure transmitters. There are also specialized devices for measuring pressure extremes, such as vacuum pressure.

Pressure Gauges

Pressure gauges are relatively inexpensive mechanical devices that, for the most part, are read manually. One of the most well-known types is called the Bourdon gauge, which was patented in France by Eugene Bourdon in 1849. In 1852, Edward Ashcroft bought the American rights to the design of the Bourdon gauge and founded the Ashcroft Manufacturing Company to make pressure gauges for steam engines. This was the beginning of the company that is today known as Ashcroft Inc. Ashcroft is located in Stratford, Conn., and it still sells pressure gauges, along with a variety of other products, including pressure transducers and transmitters, pressure and temperature switches, and test instruments.

Bourdon gauges contain a thin-walled metal tube that is typically threaded into the compartment where pressure is being measured. As pressure increases in the tube, the tube begins to straighten. On the other end of the tube is a lever system that contains a pointer. As the tube straightens, the pointer moves around a dial, indicating pressure in pounds per square inch (PSI). Common tube shapes include curved or C-shaped, spiral and helical. This is a mechanical device that is manually read. Another type of mechanical gauge that operates in a similar fashion and also contains a pointer is called a diaphragm gauge.

Traditional gauges, such as the Bourdon and diaphragm gauges, are sensitive to vibration and condensation. Another type is called a “filled” pressure gauge, and it is filled with a viscous oil. This design has fewer moving parts than the traditional pressure gauges and is more reliable. This design dampens pointer vibration and is not susceptible to condensation.

Pressure Sensors

Pressure sensors operate by sensing pressure and converting it into an electrical quantity. Two of the main types used are piezoresistive and capacitive. Piezoresistive is the most commonly used.

Piezoresistive materials change resistance to the flow of current when they are strained or compressed. A piezoresistive pressure sensor consists of a micro-machined silicon diaphragm that has a piezoresistive strain gauge diffused into it. The diaphragm is fused to a silicon or glass backplate. The sensor contains resistors that are typically arranged in the form of a Wheatstone Bridge Circuit. As pressure increases on the silicon, it is more resistant to current passing through it. As a result, the output of the Wheatstone Bridge is proportional to pressure.

Capacitive pressure sensors use a thin diaphragm as one plate of a capacitor. This diaphragm is usually metal or metal-coated quartz. The diaphragm is exposed to a reference pressure on one side and to the process pressure on the other. Pressure changes cause changes in the capacitance. Pressure changes can be determined by monitoring the changes in capacitance values.

Pressure Transducers

Pressure transducers resemble pressure transmitters, but they are generally lower in cost and smaller than pressure transmitters. They often have loose wires at one end and do not perform at the same level as pressure transmitters. Pressure transducers are widely used in the discrete industries, such as automotive and plastics. They are less typically used in the process industries.

Pressure Transmitters

While pressure sensors can detect variations in pressure by converting changes in resistance or capacitance to electrical values, these electrical signals are relatively weak. These signals are not strong enough to be transmitted over distances, or sent to a controller that may be located at a long distance from the pressure sensor. To accomplish this, a pressure transmitter is required. A pressure transmitter contains a pressure sensor plus a signal conditioner to amplify the output from the pressure sensor. Pressure transmitters also typically contain a display that shows the pressure value that is conveyed by the pressure sensor and converted into a standardized output. This output is typically either 4-20mA or a digital signal.

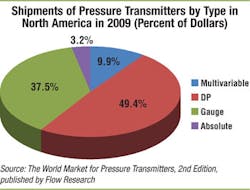

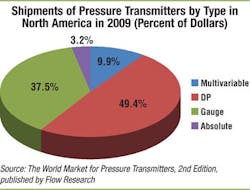

There are four main types of pressure transmitters: absolute, gauge, differential pressure, and multivariable.

Absolute Pressure Transmitters: Absolute pressure transmitters, which sense absolute pressure, are referenced to a full vacuum. The pressure of the measured media is compared against the reference pressure of an absolute vacuum in a sealed reference chamber. Absolute pressure transmitters are used to measure pressures that are not influenced by atmospheric pressures. Vacuum transmitters are often used where high accuracy is required, such as low-pressure measurement of vacuum distillation columns.

Gauge Pressure Transmitters: Gauge pressure transmitters, which sense gauge pressure, are referenced to atmospheric conditions. Gauge transmitters are vented to atmospheric pressure rather than to an absolute vacuum. Gauge pressure transmitters are widely used in the process industries to measure the pressures of liquid, gas and steam.

Both absolute and gauge pressure transmitters are growing in part by replacing pressure gauges, switches, and transducers. Pressure transmitters are more stable and reliable than pressure transducers. As end-users increasingly automate their operations and also build new plants, they are more likely to choose pressure transmitters over pressure transducers. Absolute and gauge pressure transmitters also have the advantage that, unlike differential pressure transmitters used for flow, they do not have another technology that is replacing them.

Differential-Pressure Transmitters: Differential-pressure (DP) transmitters measure the difference between two pressures. They are used for both flow and level applications. When used for flow applications, they measure the difference between pressures on the upstream and downstream side of a constriction in the pipe, called a primary element. This difference in pressure is used to compute flowrate.

DP transmitters have been used for more than 100 years to measure flowrate. They have a pronounced advantage over other types of flowmeters in installed base. Despite this, they are being displaced in some applications by new-technology flowmeters such as Coriolis and ultrasonic. This is especially the case when higher accuracy and greater reliability are required.

Multivariable Pressure Transmitters: Multivariable pressure transmitters measure two or more process variables. In many cases, they measure volumetric flow, along with pressure and temperature, and use these values to compute mass flow. Multivariable transmitters are becoming more widely used for steam and gas flow measurement. While they are more expensive than single-variable DP transmitters, they typically cost less than buying a DP transmitter along with individual pressure and temperature transmitters. Multivariable transmitters were first introduced in 1992 by Bristol Babcock, now part of Emerson Process Management.

Specialized Pressure Measurements: Measurement in a Vacuum

While pressure gauges, sensors, transducers, and transmitters can handle a wide variety of pressure measurement applications, some applications require specialized instrumentation. Such is the case with vacuum measurement, for which thermal vacuum gauges have been designed.

Thermal vacuum gauges are products designed to measure pressure in either a vacuum or in very low pressures. They employ a heated thin wire or filament. In this way, thermal vacuum gauges resemble thermal flowmeters, which place a heated wire into the flowstream and infer the flow by measuring the speed with which heat is dissipated.

Thermal vacuum gauges sense the cooling effect of a heated filament on the gases in the vacuum chamber being measured. When the constantly heated filament is placed in a gas, the surface temperature of the heated filament is a function of the surrounding vacuum. At higher pressures, there are more gas molecules, and so the surface temperature cools more. At greater vacuum levels, there are fewer gas molecules, and so the surface temperature of the filament cools less. Most thermal vacuum gauges are calibrated for air, which is predominantly nitrogen. If other gases are used, an adjustment is required due to the different cooling effects of different gases. There are four main types of thermal vacuum gauges.

Thermocouple Gauges

Thermocouple gauges relate the temperature of one of its filaments in the process gas being measured to its vacuum pressure. In one method, this filament is heated by a constant electrical current of 20-200mA DC, and the thermocouple generates an output of about 20 mV DC. As the vacuum increases and the pressure is reduced, the temperature of the heated wire increases. If thermocouple gauges have a gauge controller, they can sense pressure in a range similar to those of convection-type Pirani gauges.

Pirani Gauges

Pirani gauges have an electrically heated wire in the presence of the gas for which pressure is being measured. Pirani gauges measure the amount of current that is required to keep the wire at a constant temperature. Because each gas has a different thermal conductivity, it is important to know what type of gas is being measured. Each Pirani gauge is calibrated for the type of gas it is sensing. Pirani gauges cannot measure pressures above 1.0 Torr because the thermal conductivity of gases doesn’t change above that pressure. One Torr is equal to 1/760 atmosphere, so it is quite a low unit of pressure.

Combination A Gauges

Combination A thermal gauges use a temperature-compensated tungsten wire to detect the cooling effects of convection and conduction. Combination A gauges are used to measure pressures from Atmosphere – 1e4 Torr. The ability of Combination A gauges to respond to both convection and conduction extends the measurement range. The gauge responds to the thermal conductivity of the gas at higher vacuums, and it responds to convective cooling by the gas molecules at lower conductivity.

Combination B Gauges

Combination B gauges combine a Pirani Gauge with a Hot Filament Ion Gauge or a Cold Cathode Gauge. Both types are used to measure pressures at very low vacuums. Combination B gauges can measure pressures from Atmosphere – 1 e9 Torr. As the vacuum increases, the gauge switches to the cold cathode or the hot filament technology, depending on the technology being used. This gives the Combination B gauge the widest measurement range of any type of thermal gauge.

Applications

There are many applications for thermal vacuum gauges. They are widely used in semiconductor manufacturing, freeze drying, vacuum deposition, vacuum pressure controllers, fuel-cell research, and air conditioning and refrigerator manufacturing. Almost any manufacturing process that involves measuring pressure in a vacuum, whether high or low, is a potential application for thermal vacuum gauges.

Jesse Yoder, Ph.D., is president of Flow Research Inc. in Wakefield, Mass., a company he founded in 1998. He has 22 years of experience as an analyst and writer in process control. Yoder specializes in flowmeters and other field devices, including pressure and temperature products. He has written over 110 journal articles on instrumentation topics. Dr. Yoder can be reached at jesse@flow research.com.

Flow Research is currently working on a new study, The World Market for Pressure Transmitters, 3rd Edition, which is due for release in April 2011. For more information, see www.worldpressure.com.