In 1933, radio pioneer Edwin Armstrong demonstrated a new technology that would transform broadcasting: frequency modulation (FM) transmissions capable of delivering higher-fidelity sound and less interference than amplitude modulation (AM). Eventually, FM broadcasting became standard for radio and television with a form used in today’s digital wireless communications. AM remains but FM is preferred for most purposes.

Creative engineers have found ways to adopt FM for a variety of applications, including radar for tank level measurement. The basic radar approach takes advantage of an electromagnetic wave’s ability to bounce off surfaces, including liquids. If it is possible to measure the time required for a signal to travel to the surface of the liquid, reflect and return to the device at the top of the tank, then it is possible to calculate the distance traveled and therefore level. This is the working concept of both noncontacting radar (NCR) and guided-wave radar (GWR) level measurement. Radar level instruments provide a top-down, direct, accurate and reliable measurement of the distance to the surface of liquids, sludges, slurries and some solids.

GWR transmits a pulse down a wave-guide probe (see Figure 2), which might extend all the way to the bottom of the tank. This guides the pulse and helps concentrate the reflection, so it is unaffected by objects inside the tank that might cause an undesired reflection. The downside is the potential for the probe to interfere with moving objects such as an agitator.

Figure 2. GWR sends a pulse down a wave guide to minimize dissipation of the signal.

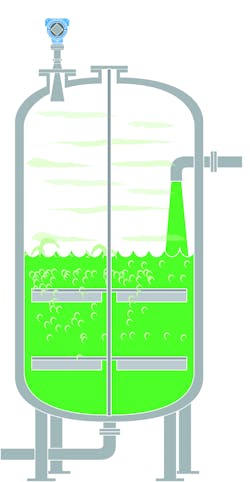

NCR technology (see Figure 3) sends a signal through the open head-space in a tank down to the stored product surface. Since it does not touch the contents, it is unaffected by many process conditions such as density, viscosity, conductivity, coating and vapor. It is also an ideal choice for tanks with moving objects, corrosive products, wide temperature range and difficult pressure conditions, since these have no impact on measurement accuracy. With built-in diagnostic capabilities, straightforward commissioning and no moving parts, NCR instruments offer both ease-of-use and low maintenance requirements.

Figure 3. NCR minimizes extension into the tank and does not touch the product.

Moving into the FMCW age

Given that the distance from a radar instrument to the surface of a tank’s contents could be a little more than a foot or two, the amount of time required for the pulse to travel is virtually instantaneous. Getting an accurate measurement of something so quick requires some clever engineering. NCR uses one of two methods: pulse or frequency-modulated continuous wave (FMCW). GWR uses pulse, but the more focused signal provided by the wave guide creates different operating characteristics than NCR.

Pulse systems use time expansion to convert these extremely short intervals to a slower timescale. The surface echo is built up of tens of thousands of short radar pulses transmitted from the instrument at the tank top and aimed directly at the process material below. The instrument measures the time delay between the transmitted and received echo signal, and an on-board microprocessor then calculates the distance to the material’s surface and, consequently, the level measurement.

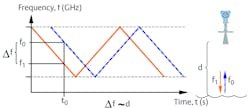

FMCW uses the same reflected signal concept but applies it differently. Instead of measuring time-of-flight of a specific pulse, an FMCW instrument transmits a continuous signal from the antenna at the tank top, but with a constantly changing frequency (see Figure 4). After the signal is reflected by the surface of the contents, the echo is picked up by the antenna. Since the transmitted signal constantly varies in frequency, the echo has a slightly different frequency compared to the signal being transmitted at that moment. The difference between these frequencies is directly proportional to the echo delay, enabling distance to be accurately measured.

Figure 4. The ability of FMCW to use frequency change for determining distance can help avoid problems that affect pulse measurements.

The difference between these two approaches is analogous to AM versus FM radio broadcasting. Pulse systems are more like AM in that the signal is more susceptible to interference from sources such as internal tank structures, foam, high vapor concentrations and turbulence. For example, if turbulence is bad enough, a pulse may be scattered and effectively lost due to a poor reflection. The instrument may incorrectly assume the reflection from the next pulse is actually the lost pulse, but with a much later return time, causing it to read a distance greater than actual. Measurement accuracy can also be influenced by any drift of the pulse frequency and even temperature inside the tank.

FMCW captures its process variable information in the frequency domain, which supports more accurate signal conversion. Its signal processing can ignore the common interference sources. Moreover, FMCW has higher receiving sensitivity and uses higher-strength signals than pulse systems, helping it to perform better in difficult situations where there may be turbulence and foam.

Why we still have both — pulse and FMCW

Just as FM radio has not eliminated AM, there are still lots of pulse technology radar instruments available. Why have these not been replaced by FMCW?

FMCW isn’t new — in fact, the technology has been around for decades, and its technological advantages have been recognized since the beginning. The reason so many pulse instruments remain is largely related to power consumption. Pulse instruments are efficient to the extent that GWR instruments using WirelessHART can operate for years at a time on batteries.

As for FMCW, the working assumption all along was that they were, by definition, big, bulky four-wire devices and would consume, at least by instrumentation standards, a lot of power. If a power source was not convenient, many users stuck with pulse instruments unless some process condition demanded the more sophisticated approach.

That situation has changed. Like many electronic devices, FMCW instruments have become far smaller and more efficient with improved power utilization. Therefore, two-wire FMCW NCR instruments (such as the one shown in Figure 1) have emerged on the market and are growing in popularity.

Types of applications where FMCW shines

The following are a few examples of the types of applications that lend themselves well to FMCW instruments.

Foam: Foaming liquids can disrupt echo reflection, and the extent to which this interferes with an accurate measurement can be difficult to predict and depends largely on the foam’s properties. One kind may dampen out the signal completely, while other types may be transparent. The thickness, density and dielectric constant are key factors that need to be analyzed. Dry foam tends to be transparent, so the instrument reads the actual liquid surface. If the foam is wet or especially dense, the microwaves are often reflected from the foam surface, and the top of the foam is seen as the level. The latest FMCW instruments have a double-surface handling function, allowing the user to select either the foam layer surface or underlying product surface as the output. This enables the product surface to be measured rather than the foam layer.

FMCW has higher receiving sensitivity and uses higher-strength signals than pulse systems, helping it to perform better in difficult situations where there may be turbulence and foam.

Condensation: FMCW technology is generally unaffected by condensation and low-pressure steam, but heavy condensation on the antenna can affect the measurement. When this is a problem, air purging may be required to prevent clogging of the antenna. In high-temperature applications, mounting the transmitter in an insulated tank spud is recommended. Insulation prevents the nozzle from becoming a cold spot, causing condensation and liquid buildup on the antenna. In extreme situations, heat tracing may be necessary to keep the spud above the dew point.

Storage, buffer and blending tanks: FMCW technology delivers highly reliable and accurate level measurements when applied to both metallic and nonmetallic vessels containing any liquid, including oil, gas condensate, water or chemicals. As these transmitters have no moving parts and do not contact the product, they reduce maintenance and improve safety. If agitators are necessary, sophisticated FMCW instruments can use software to see past false echoes so measurement accuracy is unaffected.

Reactor vessels: Chemical reactions can create a variety of conditions inside tanks — often resulting in vapors, foam and turbulence — while density can change as part of the reaction, and pressure can vary from vacuum to positive pressure. FMCW instruments can cope with these factors to provide measurement accuracy and reliability.

Still pipes: When a tank’s content is turbulent — whether from agitation, product blending or splashing — an effective return signal can be disrupted. Adding a still pipe can reduce the effect by isolating the surface and reducing turbulence. These situations often call for GWR, but FMCW instruments can also provide accurate readings within the confined space of the pipe.

Conclusion

The two main modulation techniques for NCR instruments — pulse and FMCW — are both effective, but with its greater sensitivity and accuracy, FMCW is suited for challenging applications. Today’s FMCW products are more compact and provide high energy efficiency, allowing operation with the low power supplied by a two-wire loop. This eliminates the need for additional power infrastructure and enables these devices to provide accurate and reliable level measurement in a wider range of challenging applications.

Ingemar Serneby is a senior application specialist with Rosemount Tank Radar, Emerson Automation Solutions. He has an electrical and electronics engineering degree from Chalmers University of Technology and has worked for Emerson for nearly 30 years.