Some have said, “experience is the best teacher.” This adage not only applies to life in general, but also in the quest for the most effective process for the sizing and selection of valves for industrial applications.

Unfortunately, even today, valve sizing and selection is not typically experienced-based. Instead, the sizing and selection process all too often relies on standard equations and rules of thumb, which are applied to valve performance data collected in the manufacturer’s laboratory. The laboratory data is very accurate in itself. However, the rules of thumb make very broad assumptions about flow conditions that will be present in the actual system.

Often, this assumptive process is good enough and the valves selected will be durable and adequate to their purpose. On the other hand, when valves misbehave and the result is poor process control, reduced output, component degradation due to noise, vibration and cavitation, and unscheduled downtime, the root cause of the problem is likely an inadequate selection process due to the over-reliance on generalized rules of thumb.

This problem can be fixed. Over several decades, valve manufacturers have collected performance data on tens of thousands of valves in the field under actual line conditions. In the early days, this research involved going to the installation and measuring relevant conditions. Within the past decade, microprocessor-based data collectors embedded in valve controllers have geometrically expanded the amount of data available for process system modeling. Users who take the time to accurately model their processing line conditions can now rely on more accurate equations so that they can select and size valves, actuators and trim with a substantially higher degree of resolution.

Of course, modeling line conditions and applying line-specific equations to a range of possible valve choices until the best fit is obtained can be very time consuming. This is where expert sizing and selection software comes in. This software incorporates the manufacturers’ laboratory data and experienced-based sizing algorithms. The software has the intelligence to guide users through a semi-automated line modeling and component selection procedure during which various flow performance outcomes are observed as various valves and components are swapped in and out of the system. This results in the best possible combination of valves, actuators and trim for the process loop in question.

Expert sizing software compresses what used to take days into hours and minutes and yields sizing and selection information for critical valve applications that can frequently deliver a huge payback in terms of improved process safety and productivity.

Many Variations

Several manufacturers have offered expert sizing and selection software and refined their selection processes and algorithms over many successive years—sometimes decades. While they all, to some degree, make selection and sizing easier, they also have unique differences in terms of the operator interface, library of valve types, models, actuators and trim components available, and the variety of analyses that can be performed. Some users who want to compare components from different manufacturers may find this tool frustrating, since vendors can only include their own products in the library, and they don’t have access to all of the competitor options and performance data.

Until recently, most expert sizing software focused on control valve applications. This makes sense because control valves are most critical for assuring optimum process performance, end-product quality, and productivity. However, over the years, releases of expert software have added new analytical capabilities and valve types. For example, new calculation modules have been introduced that enable the selection of intelligent automated on/off valves and emergency valves.

An on/off calculation tool allows the selection of metal- and soft-seated on/off valves with advanced actuator sizing, including adjustable safety factor and torque key figures. By using the tool, users can select the actuator more quickly and accurately in the engineering phase. They can also use the mass calculation tools to select a number of interrelated package components simultaneously.

For ESD (Emergency Safety Device) valve sizing, safety requirements (such as an actuator-sizing safety factor or a complete valve assembly safety integrity level) can be evaluated using special tools within the software program. The SIL (Safety Integrity Level) module for final element PFD (Probability of Failure on Demand) calculation allows both 1oo1 and 1oo1D (D standing for diagnostics) final-element calculation that takes into account the use of a valve, an actuator, and a partial-stroke test device. In addition, one-to-several pneumatic components can be taken into account in the calculation.

How It Works

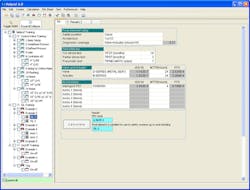

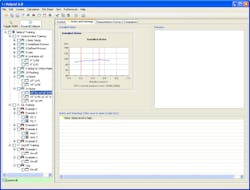

Successful control valve sizing and selection depends on knowing the actual process conditions in the system in which the valve is to be installed. This information is rarely available first hand. The more assumptions one has to make on flow conditions, the less accurate control valve sizing is going to be. Fortunately, when a few flow conditions are known accurately, an algorithm can be found that can model the behavior of a given control valve for the whole flow range. Expert sizing software leads the user through a sequence of data input steps, which allows for the calculation of this algorithm.

Expert software predicts the performance of the control valve package as a part of the system before installation. By comparing the predicted performance of different valves, users can quickly arrive at the most appropriate control valve package to ensure the desired process performance. This procedure allows users to avoid oversizing of valves and undersizing of actuators, reducing valve acquisition and maintenance costs while optimizing process control.

For example, the selection of a control valve is divided into two parts. First, the mechanical selection in which suitable valve style, materials and pressure rating are selected to guarantee safe and reliable performance according to good engineering practices and local laws and regulations. This selection should be made using bulletins and technical information specific for each valve type.

Then comes sizing, which is an iterative process resulting in the selection of valve package components that meet process control objectives while preventing unwanted phenomena such as excessive noise or liquid cavitation. After the valve size has been determined, other valve package components can be fine-tuned to optimize the installed performance of the valve to phase out such undesirable control characteristics as hunting, excessive slow, or fast response and poor accuracy.

One way this is done is by adjusting controller response patterns to compensate non-linearities detected in the valve’s installed flow characteristic curve. Expert sizing software presents the user with a broad range of mathematical correction and compensation tools to linearize control valve performance as much as possible.

Troubleshooting Specific Conditions