The ultrasonic flowmeter market is one of the fastest-growing flowmeter markets in the world, and the technology is rapidly evolving to overcome traditional and new challenges. Ultrasonic meters dominate the gas custody transfer market — one of the fastest-growing areas within the entire flowmeter market. Ultrasonic flowmeters are heavily dependent on the oil and gas industry, and that is one of the reasons for growth in this market. Other forces, such as continued population growth and economic expansion, are also fueling growth.

Many end-users are replacing traditional flowmeters — especially turbine and differential pressure (DP) types — with ultrasonic flowmeters. At the same time, ultrasonic suppliers are exploring ways to take market share away from Coriolis, positive displacement and turbine flowmeters, including by accommodating complex conditions in the upstream gas market where the conventional meters are strong. Ultrasonic meters can accurately measure either liquids or gases and outshine Coriolis meters in gas. Ultrasonic flowmeters are being more widely used in the chemical and refining industries to measure process gases. These meters are an alternative to magnetic flowmeters that cannot meter nonconductive liquids or gas. Insertion and inline ultrasonic meters will continue to be used to meter flare gas in large pipes.

Suppliers are pouring considerable research and development effort into ultrasonic flowmeters, perhaps at the expense of other meters such as vortex and turbine. They have enhanced the accuracy and reliability of ultrasonic flowmeters, most significantly by increasing the number of paths or chords, which increases the number of measurement points. They have also introduced dual transmitters, sophisticated sensors, microprocessors, lithium batteries, titanium and other materials.

Advanced detection and validation is also improving reliability. Suppliers are enhancing path configurations and diagnostics and incorporating self-verifying techniques. These enhanced capabilities are eliminating the need for flow conditioners and are also increasing the ability of ultrasonic meters to determine sources of error, including foreign materials and non-gas fluids. Remote user access to real-time flow phenomena such as crossflow and swirl angle enables users to quickly identify and address flow disturbances with corrective actions.

Early history

Tokyo Keiki first introduced ultrasonic clamp-on flowmeters to commercial markets in Japan in 1963. In 1971, Badger Meter first brought clamp-on ultrasonic flowmeters to the United States by reselling Tokyo Keiki’s meters. In 1972, Controlotron began manufacturing its clamp-on ultrasonic flowmeters in Long Island, New York. In the late 1970s and early 1980s, Doppler flowmeters began to be used. Because they were not well understood, they were often misapplied. As a result, many users got a bad impression of ultrasonic flowmeters during this time. In the 1990s, transit-time emerged as the leading ultrasonic technology, and ultrasonic meters began growing significantly in popularity and capabilities.

In the early 1980s, both Panametrics and Ultraflux experimented with ultrasonic meters for gas-flow measurement. In the mid-1990s, a group called Group Europeen de Recherches Gaziers (GERG) published a technical monograph on ultrasonic flowmeters for gas flow measurement. A monograph out of GERG led to increased European ultrasonic flowmeter use from 1996 to 1999.

The GERG monograph laid the groundwork for the publication of AGA-9 by the American Gas Association. AGA-9 lays out criteria for using ultrasonic flowmeters for custody-transfer applications. Since its publication in June 1998, ultrasonic flowmeters have become widely used for custody transfer of natural gas. They are especially suited for measuring gas flow in large pipelines, easily handling flow in those above 20 inches in diameter, as well as smaller pipelines. Its main competitors for custody transfer of natural gas are the differential-pressure (DP) orifice meter and turbine flowmeter.

Principle of operation

There are two main types of ultrasonic flowmeters, transit time and Doppler:

Transit time ultrasonic flowmeters

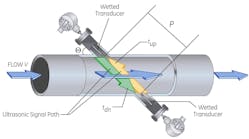

A transit time ultrasonic flowmeter has both a sender and a receiver. It sends two ultrasonic signals across a pipe at an angle: one with the flow, and one against the flow. The meter then measures the “transit time” of each signal. When the ultrasonic signal travels with the flow, it travels faster than when it travels against the flow. The difference between the two transit times is proportional to the flowrate.

Transit time ultrasonic flowmeters are distinguished according to the number of “paths” they have. A path is simply the path or track of the ultrasonic pulse as it travels across the pipe and back again. Many ultrasonic flowmeters are single or dual path, meaning that they send either one or two signals across a pipe and back. Typically, there are two transducers for each path; one is a sender and one is a receiver.

Doppler flowmeters

Doppler flowmeters also send an ultrasonic signal across a pipe. Instead of tracking the time the signal takes to cross to the other side, a Doppler flowmeter relies on having the signal deflected by particles in the flowstream. These particles are traveling at the same speed as the flow. As the signal passes through the stream, its frequency shifts in proportion to the mean velocity of the fluid. A receiver detects the reflected signal and measures its frequency. The meter calculates flow by comparing the generated and detected frequencies. Doppler ultrasonic flowmeters are used with dirty liquids or slurries. They are not used to measure gas flow.

Multipath meters for custody transfer

Probably the single-most important factor in the recent growth of ultrasonic flowmeters in the past two decades has been the rapid growth in the market for multipath ultrasonic meters for custody transfer of natural gas. This market includes natural gas, process gases and flare gas. Of these three, the market for natural gas flow is expected to show the strongest growth. This market involves the use of multipath ultrasonic flowmeters for custody transfer.

Multipath transit time flowmeters use more than one ultrasonic signal or “path” in calculating flowrate. Typically, multiple pairs of sending and receiving transducers determine flowrate, with the transducers alternating in their function as sender and receiver over the same path length. The flowrate is determined by averaging the values given by the different paths, providing greater accuracy than single-path flowmeters. By strategically locating the positioning of these paths, the flowmeter measures flow at multiple points of cross-section within the flowstream’s profile, leading to greater accuracy.

Clamp-on meters growing in popularity

Early on, some end-users had problems installing clamp-on meters correctly. Many of these doubts have been eliminated by improved technology and by user experience. Many end-users have come to understand and appreciate the advantages of clamp-on flowmeters. These advantages include high turndown ratios, long service life, low maintenance, relatively low cost, valuable diagnostics, no moving parts, bi-directional flow measurement and redundancy capabilities. Clamp-on meters are relatively easy to install, and do not interrupt the flow or cause pressure drop. They are small, lightweight and come in a wide range of pipe materials and sizes. They do especially well in large line sizes.

Frontiers of research

There are many frontiers of research for ultrasonic flowmeters. These include introducing more measurement paths, providing better diagnostics, increasing the accuracy of inline and clamp-on meters, using lighter and more durable materials of construction, and providing more redundant measurement. Another frontier is measuring raw natural gas at gas production wells and pipelines. This gas often contains natural gas liquids, dirt, dust and other particles.

Another important frontier is hydrogen measurement. Some ultrasonic flowmeter manufacturers now offer meters that measure hydrogen and are exploring how to best measure hydrogen and hydrogen blends. They are also eyeing whether to enter the renewable energy market, which includes hydrogen renewable natural gas from methane and synthetic fuels. Hydrogen’s physical properties are quite different from other gases, including natural gas, and flowmeter suppliers have had to adapt to those differences, as well as figure out ways for ultrasonic meters to accurately measure hydrogen blends.

Ultrasonic flowmeters have a bright future

Ultrasonic flowmeters will continue to benefit from the expanding oil and gas market, including high oil prices. They will also benefit from the growing U.S. economy, which appears to be making a “soft landing.” The leading suppliers are making many technological improvements. And Emerson’s acquisition of FLEXIM late in 2023 gives new prominence to clamp-on meters. Look for the ultrasonic meter market to continue to expand as suppliers meet new measurement challenges.

Dr. Jesse Yoder is president of Flow Research Inc., a company he founded in 1998. Dr. Yoder has 35 years of experience as a writer and as an analyst in process control and instrumentation. He has written more than 280 market research studies, most of them regarding flow and instrumentation. Dr. Yoder has also written more than 300 articles on flow and instrumentation for trade journals. Many can be found at www.flowarticles.com.

Flow Research