The recession of 2009 had a significant impact on the flowmeter market, as many end-user companies canceled projects or put them on hold. The good news is that the flowmeter market rebounded in 2010 and has continued to show signs of strong growth in 2011 and in early 2012.

The flowmeter market does not exist in a vacuum though; it is subject to the same economic pressures and influences as chemical, food & beverage, and other process markets. In addition, the flowmeter market today is actually made up of more than a dozen submarkets, each corresponding to a different flow technology.

One of the broad trends in the flowmeter market is the transition from traditional technology flowmeters to new-technology meters. While this transition is continuing, many traditional meters are holding their own due to their large installed base and a large number of suppliers. However, the picture is different for each type of meter.

Considering New-Technology Flowmeters

New-technology flowmeters share several characteristics:

1. They were introduced after 1950;

2. They are a main focus of research and new product development by flowmeter suppliers; and

3. Their performance in areas such as accuracy and reliability is generally at a high level.

New-technology flowmeters include Coriolis, magnetic, ultrasonic, vortex, and thermal.

Coriolis Flowmeters

Some of the most dramatic developments in the world of flow today are occurring in Coriolis meters. While the large majority of Coriolis flowmeters still have a line size of 2 inches or less, some major developments are occurring involving large-line size Coriolis meters. Rheonik (now part of GE) used to be the only company that manufactured Coriolis meters in line sizes above 6 inches. Today, several other companies have entered this market and are producing Coriolis meters that fit in line sizes from 6 to 16 inches.

Endress+Hauser and Emerson, Micro Motion both produce bent-tube Coriolis meters that fit in this line size range, while KROHNE produces a straight-tube meter for line sizes from 6 inches to more than 10 inches.

One important distinction within Coriolis meters is between bent-tube and straight-tube meters. Even though the majority of Coriolis meters are still of the bent-tube variety, straight-tube meters have made significant inroads into liquid measurement. They have been less successful in measuring gas flow. KROHNE introduced the first commercially successful straight-tube meter in 1994. Straight-tube meters have a distinct advantage in size and weight when it comes to making meters for line sizes of 10 or more inches.

Magnetic Flowmeters

Magnetic flowmeters have the disadvantage that they cannot be used to measure gas, steam, or nonconductive liquids such as oil. On the other hand, they do an excellent job of measuring liquids, whether clean or dirty. Magnetic flowmeters are particularly popular in Europe where the leading suppliers reside. Europe also has a larger population than the United States in a much smaller geographic area. This requires more measurement of water and other liquids and also requires better resource management.

It used to be commonplace that AC (alternating current) magmeters were used to measure dirty liquids, and DC (direct current) magmeters were used for cleaner liquids. However, just as ultrasonic suppliers have improved transit-time technology, magnetic flowmeter suppliers have improved DC technology to be able to handle liquids with some impurities. They have also introduced high-strength DC meters to better handle noise issues.

Ultrasonic Flowmeters

The ultrasonic flowmeter market is the fastest growing of any flowmeter type, with the exception of the emerging technology of multiphase meters. It is actually composed of a number of submarkets that differ by type and application. This makes the market as a whole somewhat complex.

One way to look at the market is by the method used to produce the ultrasonic signals that detect flowrate. The methods used are transit time, Doppler, and hybrid. Transit-time ultrasonic transducers send a signal across a closed pipe and bounce the signal back to the other side. A receiving transducer detects the returning signal. When the signal travels with the flow, it travels faster than when it travels against the flow. The flowmeter uses this difference to compute flowrate.

Transit-time meters do best in clean fluids, but recently suppliers have made transit-time meters that handle fluids with some impurities.

Instead of sending a signal across the pipe, the ultrasonic signal in Doppler flowmeters is reflected off of particles in the flowstream. These particles are traveling at the same speed as the fluid. As the ultrasonic signal is reflected off the particles, its frequency shifts in proportion to the velocity of the fluid. A receiver detects this frequency shift, and the flowmeter uses this information to compute flowrate. Doppler flowmeters are mainly designed for dirty liquids and liquids with entrained particles.

Hybrid ultrasonic meters incorporate both transit-time and Doppler technology, so they can be used for both clean and dirty fluids.

Ultrasonic flowmeters can also be divided into inline, clamp-on, and insertion. Inline meters require cutting a pipe so the meter can be fitted “inline” with the pipe, with either wafer or flanged fittings. Clamp-on meters can be clamped onto the outside of the pipe, which does not require cutting the pipe. The signal passes through the pipe wall and through to the other side of the pipe, then typically bounces back to a receiving transducer.

Clamp-on meters have the disadvantage that the pipe wall can interfere with their signal, so they are typically less accurate than inline meters.

Insertion meters are mounted into the pipe using a hot tap or cold tap method. They avoid the expense associated with the cost of the meter body, since they are mounted directly in the pipe. One major use of insertion ultrasonic meters is for flare and gas stack measurement where they compete with averaging Pitot tube and thermal flowmeters.

Much of the current research is going into multipath transit-time meters used for custody-transfer measurement. Suppliers have manufactured multipath meters with from three to 18 paths. A high number of paths does not automatically guarantee higher accuracy, but some paths are used for diagnostic purposes. Having three or more paths rather than just one or two does make for higher accuracy, which is why multipath flowmeters are used for custody-transfer applications.

Considering Traditional-Technology Flowmeters

Traditional-technology meters have the advantages of longevity and large installed base over new-technology meters. Traditional- technology meters possess the following characteristics:

1. They were introduced before 1950.

2. They are less the focus of research and product development than new-technology meters;

3. Their performance in terms of accuracy and reliability is generally not as high as that of new-technology meters; and

4. They are also less likely to adopt smart communication protocols and typically have a lower level of self diagnostics than do new-technology flowmeters.

Traditional technology meters include differential pressure (DP), positive displacement, turbine, open channel, and variable area.

One area where positive-displacement meters still have a decided advantage over other types is in commercial and industrial utility of gas for consumption by businesses, industrial plants, and large structures such as apartment buildings. Here there is a trend for rotary meters to replace diaphragm meters, but these are both types of PD meters. No other flow technology has yet begun to significantly penetrate this application.

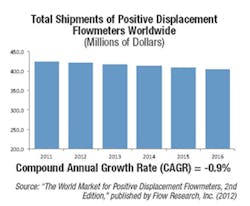

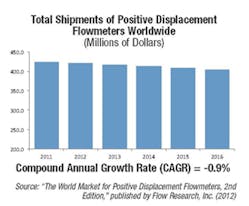

Probably the single biggest drawback to growth in the positive-displacement flowmeter market is that there does not appear to be a significant amount of research and development going on in this market. If suppliers would spend as much time and resources on product improvement and on new product development as Coriolis and ultrasonic flowmeter suppliers do, this market would have a chance to grow. Unless this begins to happen, the positive-displacement flowmeter market is likely to continue to decline.

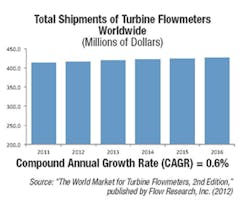

Turbine flowmeters do have the disadvantage of having moving parts that wear over time. Suppliers have responded by introducing more durable bearings, different rotor designs, dual rotors, and bi-directional capability. Some suppliers are continuing to offer the same products as before and are not actively engaged in new product development. Others are choosing to expand their product line to include other technologies rather than improving their existing turbine technology.

Winning the Battle for Market Share

Regardless of whether turbine and positive-displacement meters are growing slowly or declining slowly, they are still losing market share to new-technology meters. The Coriolis and ultrasonic flowmeter markets are growing in the range of 6 percent to 8 percent per year. So while the turbine flowmeter market is growing very slowly, and the PD flowmeter market is declining slightly, their percent of the total flowmeter market is declining. This fact is not likely to change in the foreseeable future.

How Oil & Gas Is Driving Flowmeter Development

The gas flowmeter market is a large and diverse market. It is being driven by the world’s need for energy. Some of the most exciting and dynamic segments of this market include shale gas, liquefied natural gas (LNG), and compressed natural gas (CNG). In addition to natural gas, measuring the flow of industrial gases such as argon and nitrogen is also an important and growing market.

Probably the fastest growing niche within the flowmeter market is the market for ultrasonic flowmeters for custody transfer of natural gas. This is due mainly to the growth in pipeline applications for natural gas distribution. However, the multiphase flowmeter market is another segment within flow that is growing at about the same rate as the custody transfer ultrasonic market. Multiphase flowmeters are much more expensive than ultrasonic flowmeters, but the technology is less developed. Multiphase flowmeters are used at the wellhead to determine the amount of water, gas and oil coming out of the ground.

As oil prices have risen to exceed $100 per barrel, measuring it accurately and reliably has become more important than ever before. In addition, it has become profitable to drill in wells that were not profitable at lower oil prices. New advances in the hydraulic fracturing process have made it possible to get more oil and gas out of existing wells. Despite declines in the oil fields of Mexico and the North Sea, a steady stream of new oil and gas finds is keeping oil and gas producers busy drilling in many new places, including subsea locations. Furthermore, the need for LNG in the Asia-Pacific region is generating new methods of transporting natural gas, including floating production, storage, and offloading (FPSO) units.

Like Life, Variety is the Spice of the Flowmeter World

The most exciting developments today are in ultrasonic, Coriolis, and multiphase flowmeters. This is where the bulk of the research and development money is going, and these are the meters that are mainly meeting the growing demands of the energy market today. However, turbine and positive-displacement flowmeters still have their place, and they still have niche applications where they are the best solution. So just as it takes many different kinds of people to make the world go round, it takes many types of flowmeters to measure the fluids that go through round pipes.

Jesse Yoder, Ph.D., is president of Flow Research Inc. in Wakefield, Mass., a company he founded in 1998. He has 24 years of experience as an analyst and writer in process control. Dr. Yoder specializes in flowmeters and other field devices, including pressure and temperature products. He has written over 170 journal articles on instrumentation topics. Dr. Yoder can be reached at [email protected].