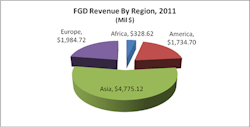

Coal-fired power plant operators will complete investments of $8.8 billion for flue gas desulfurization (FGD) systems starting operation in 2011, according to a report by McIlvaine Company. The investment in 2012 will be down and will bounce back in 2013.

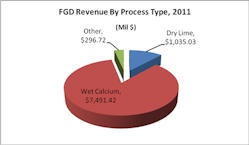

Wet calcium systems account for the large majority of the units, according to McIlvaine. These units use either limestone or lime and produce calcium sulfate or gypsum. If an additional oxidizing step is incorporated, the gypsum is suitable for wallboard. In fact, in Europe most wallboard is produced from FGD gypsum.

The dry systems are segmented into spray driers and circulating dry scrubbers (CDS). McIlvaine says the CDS systems are carving out a larger market share due to the ability to handle coals with higher sulfur levels.

U.S., European and Japanese suppliers of systems compete globally. Many are divisions of boiler companies and are capable of providing complete generation plants. A number of Chinese companies will also be contending in the international market in the future.