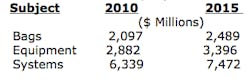

The world market for fabric filters and bags to remove pollutants from stack gases will grow modestly to $10 billion in 2015, up from $8.3 billion in 2010, according to a report by McIlvaine Company.

The total market is defined as bags plus systems. Equipment is included as part of systems. McIlvaine says the market for bags will increase by 20 percent in this period, while the market for equipment and systems will be quite erratic. The reason is the large swing in the market for fabric filters for coal-fired power plants. One large power plant could require the investment of over $100 million for a filter system. In some years, there are 10 more new large plants forecasted than in the previous year or the subsequent year. So the equipment and systems markets will vary considerably from year to year. Growth in the Chinese fabric filter market will continue to be significant, as it is already the leading purchaser. China will represent 29 percent of the total market in 2015 vs. only 18 percent of the total for the U.S. The cement market in China will continue to be larger than the rest of the world combined. China has more power plants, but presently electrostatic precipitators are preferred over fabric filters for this application. The one growth market in the U.S. is retrofitting cement plants to meet the new air toxic regulations. This could result in over 100 new fabric filter systems, with an investment of over $0.5 billion. The Asian market generally will experience growth well above the rest of the world. The expansion of heavy industry in this region will be substantial. Foundries, steel mills, cement and chemical plants all require investment in fabric filters. In Europe, biomass combustion is the biggest growth market. The industry is served by a small number of resin and other material suppliers, a modest number of media suppliers, and large numbers of bag and equipment companies. Media and resin companies are strategically locating global manufacturing facilities. There is a big demand for high temperature bags. The selling price is many times that of a conventional low-temperature polyester bag. Cartridges continue to gain market share over tubular bags. Membranes are gaining on non-wovens.